Phosphonate structure-containing ionic monomer and flame-retarding and smoke-suppressing ionomer synthesized under catalysis of ionic monomer, and preparation methods and applications thereof

A technology of ionic monomer and phosphonate, which is applied in the field of flame-retardant and smoke-suppressing copolyester ionomer and its preparation, and reactive ionic monomer, which can solve the problems of poor cationic dyeing performance, increased processing cost, and human health hazards, etc. problems, achieve excellent catalytic ability, high degree of polymerization, and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

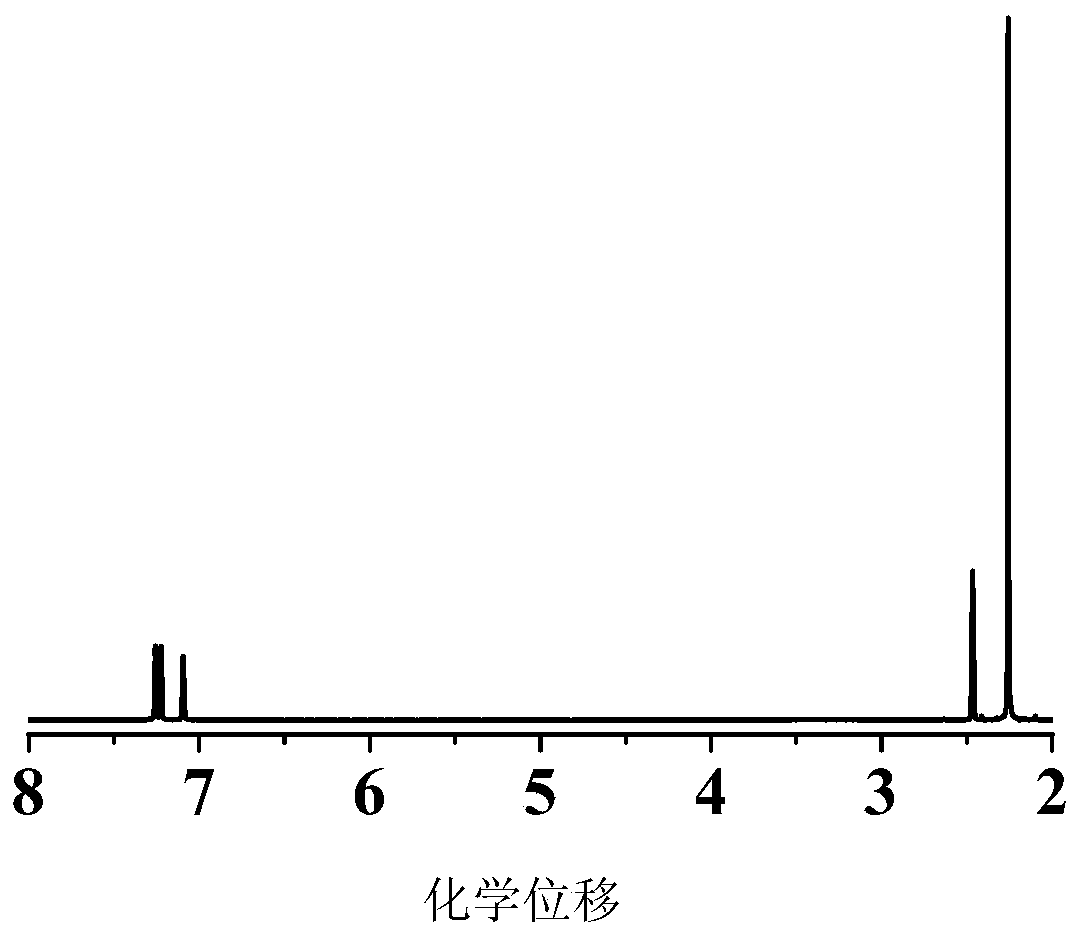

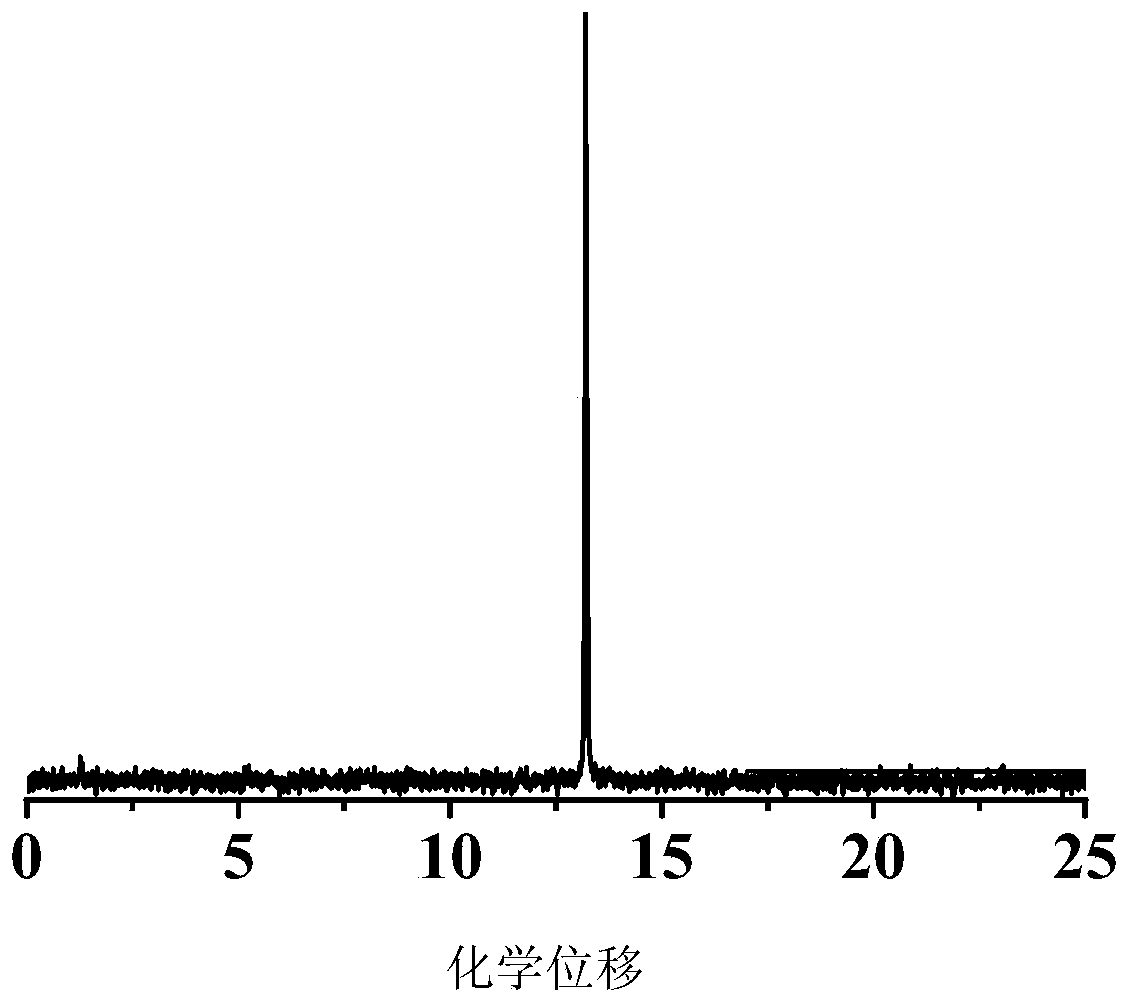

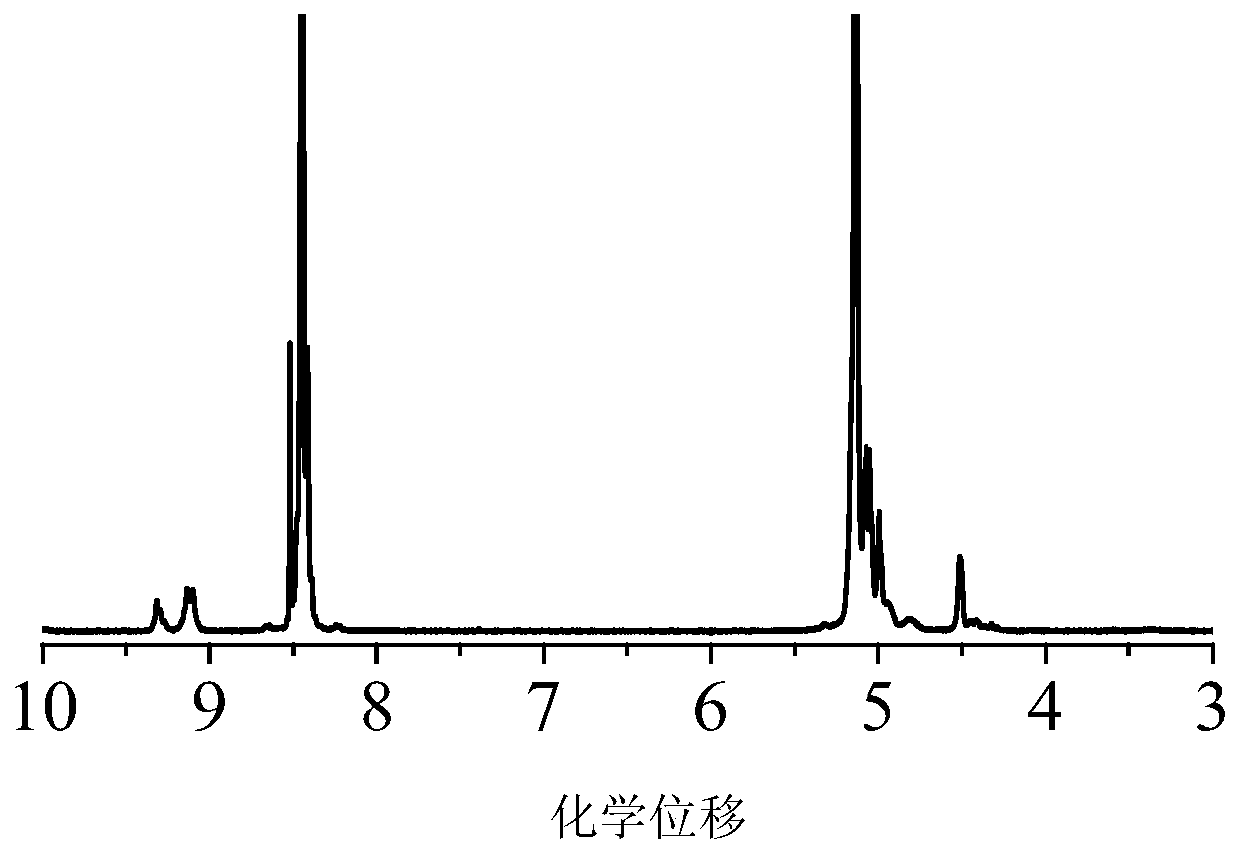

Embodiment 1

[0064] Add 274g of dimethyl isophthalate-5-phosphonic acid, 200g of potassium bicarbonate and 1L of water into the reaction vessel, and then dissolve them completely under magnetic stirring and slowly raise the temperature to 50°C, while vacuuming with a water pump. After 60 minutes of reaction, the stirring was stopped, the water was removed by rotary evaporation, and dried to obtain dimethyl isophthalate-5-dipotassium phosphate.

Embodiment 2

[0066] In the reaction vessel, add 274g of dimethyl isophthalate-5-phosphonic acid, 168g of sodium bicarbonate and 1L of water, then dissolve it completely under magnetic stirring and slowly raise the temperature to 70°C, while vacuumizing with a water pump. After 40 minutes of neutralization reaction, stop stirring, remove water by rotary evaporation, and dry to obtain dimethyl isophthalate-5-phosphate disodium.

Embodiment 3

[0068] In the reaction vessel, add 274g of dimethyl isophthalate-5-phosphonic acid, 162g of calcium bicarbonate and 1L of water, and then dissolve them completely under magnetic stirring and slowly raise the temperature to 60°C while vacuuming with a water pump. After 50 minutes of neutralization reaction, stop stirring, remove water by rotary evaporation, and dry to obtain dimethyl isophthalate-5-calcium phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com