Preparation method of composite nanofibrous membrane loaded with nanozyme and its wound dressing

A composite nanofiber and nanozyme technology, applied in the field of synthetic fibers, can solve the problems of easy ingrowth of wound granulation tissue, inability to keep the wound moist, easy to cause foreign body reaction, etc., to achieve inhibition of bacterial growth, controllable absorbability, The effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the composite nanofiber membrane loaded with nanozyme provided by the application, the preparation method adopts the following steps:

[0031] (1) 0.1-0.5 parts by weight of nanozymes are dissolved in 100 parts by weight of an aqueous solution of polyvinyl alcohol-acrylamide graft copolymer with a mass fraction of 5-15% to prepare a spinning solution;

[0032] Wherein, the nanozyme is selected from any one or more of ferric oxide, tricobalt tetroxide, trimanganese tetraoxide, and the particle size is 5-50nm; the grafting rate of polyvinyl alcohol-acrylamide graft copolymer is 45- 55%;

[0033] Further, in the spinning solution, the nanozyme interacts with the amino groups in the polyvinyl alcohol-acrylamide graft copolymer, and self-assembles together through electrostatic attraction, which increases the solubility and solution stability of ferroferric oxide. The suspension of enzyme and polyvinyl alcohol-acrylamide graft copolymer is more sta...

Embodiment 1

[0040] (1) choose 17-88 type medical grade polyvinyl alcohol, be mixed with the polyvinyl alcohol aqueous solution that mass fraction is 15%;

[0041] Add K with a concentration of 0.04mol / L to the aqueous solution of polyvinyl alcohol 2 S 2 o8 , stirred at room temperature to make K 2 S 2 o 8 Fully dissolved and mixed with polyvinyl alcohol to obtain a mixed solution, K 2 S 2 o 8 Make the hydrogen on the side hydroxyl of polyvinyl alcohol fall off to form an active center, and initiate the polymerization of acrylamide at the active center;

[0042] Add an aqueous solution of acrylamide with a mass fraction of 15% to the mixed solution, react at 40° C. for 4 hours to obtain a product solution, and the molar ratio of the added acrylamide to polyvinyl alcohol is 6:1;

[0043] After the reaction is over, wash the product solution with acetone to remove unreacted small molecules; take the organic solid phase after suction filtration, and dry it at a constant temperature at ...

Embodiment 2

[0048] (1) Get 100 mg of iron ferric oxide nanozyme with a particle size of 10-25 nm, add 100 ml of polyvinyl alcohol-acrylamide graft copolymer aqueous solution with a mass fraction of 12%, ultrasonically vibrate for 15 hours, and prepare a spinning solution;

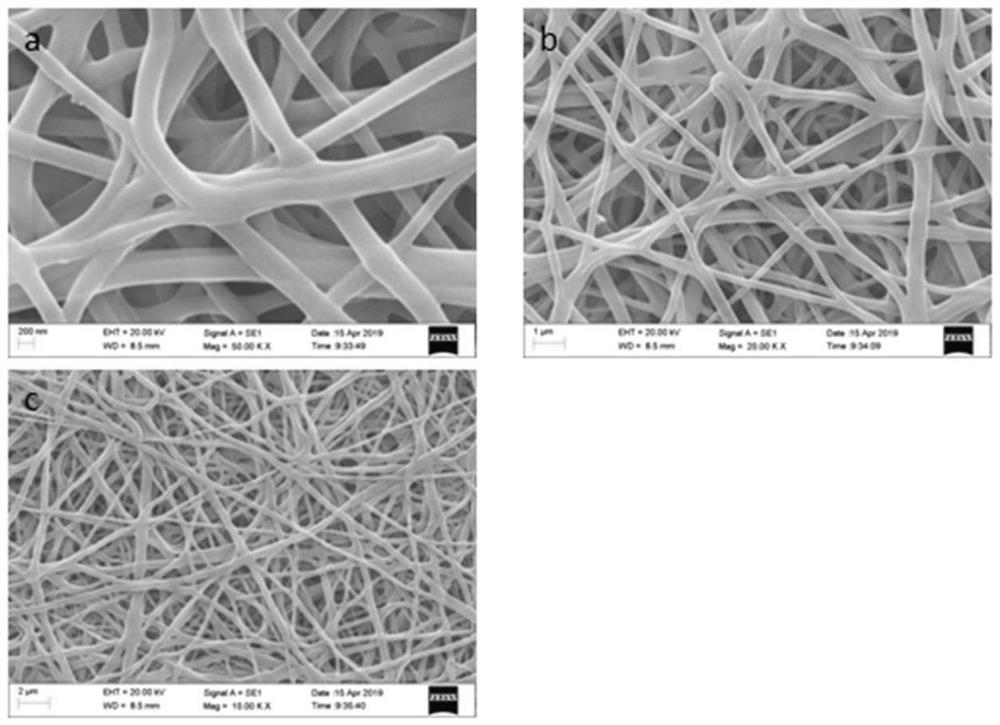

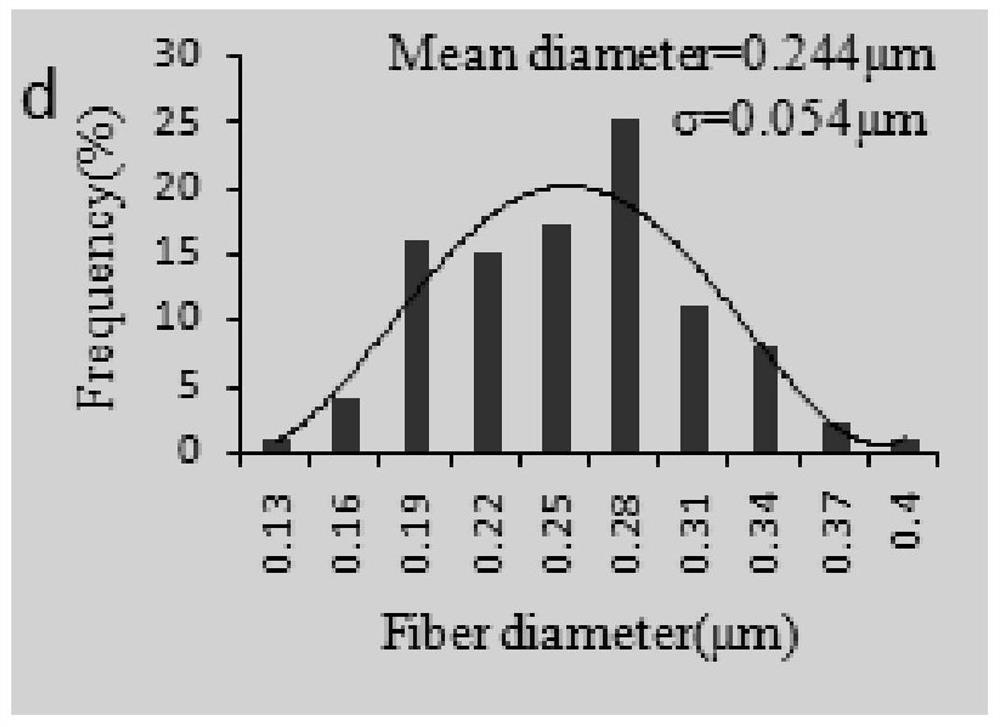

[0049] (2) The spinning solution is spun into a nanofiber film with a thickness of 0.1-0.2mm by electrospinning method using the needle-free electrospinning method, the spinning voltage is 35,000 volts, the receiving distance is 180mm, and the ambient temperature is 25°C , the ambient humidity is 35%, and the walking speed of the solution box substrate is 0.03m / min;

[0050] (3) The prepared composite nanofiber membrane was cross-linked at 120° C. for 15 minutes to obtain a composite nanofiber membrane with a desired degree of crosslinking.

[0051] This embodiment is the same as the preparation method of polyvinyl alcohol-acrylamide graft copolymer in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com