Anti-sagging APAO-modified alkyd resin water-based functional coating

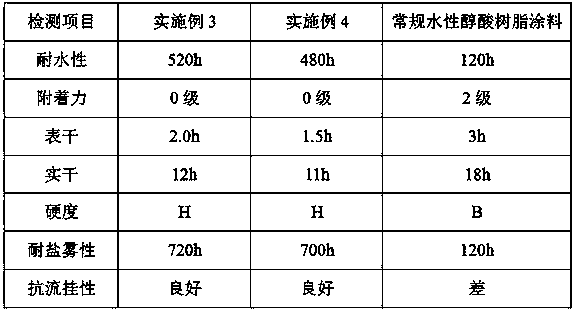

A technology of water-based alkyd resin and alkyd resin, which is applied in the direction of polyester coating, coating, etc., can solve the problems of human body and ecological environment, poor anti-sag performance, insufficient water resistance, etc., and achieve good mechanical properties, High hardness and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An APAO modified water-based alkyd resin A, consisting of the following formula in parts by weight: 26.0 parts of soybean oil, 7.5 parts of maleic anhydride grafted APAO, 28.0 parts of phthalic anhydride, 10.0 parts of terephthalic acid, and 18.0 parts of butanediol 24.0 parts of trimethylolpropane, 15.0 parts of xylene, 3.5 parts of n-heptanoic acid, 5.0 parts of dimethylolpropionic acid, 8.0 parts of triethylamine, and 130.0 parts of deionized water.

[0029] A kind of preparation method of APAO modified water-based alkyd resin A in the present embodiment, comprises the following steps:

[0030] a) In the multifunctional reaction kettle, add soybean oil, phthalic anhydride, terephthalic acid, butanediol, trimethylolpropane, dimethylol propionic acid and xylene in sequence according to the weight of the formula, and stir at a low speed Access to N 2 , to remove the O in the reactor 2 ;

[0031] b) Heat up to 110°C, keep it warm for 0.5h, remove free water, quickly r...

Embodiment 2

[0034] An APAO modified water-based alkyd resin B, consisting of the following formula in parts by weight: 20.0 parts of castor oil, 9.0 parts of maleic anhydride grafted APAO, 20.0 parts of maleic anhydride, 10.0 parts of adipic acid, trimethylol 22.0 parts of methyl propane, 9.5 parts of neopentyl glycol, 14.0 parts of xylene, 3.5 parts of n-heptanoic acid, 5.2 parts of dimethylolpropionic acid, 8.2 parts of triethylamine, and 115.0 parts of deionized water.

[0035] A kind of preparation method of APAO modified water-based alkyd resin B in the present embodiment comprises the following steps:

[0036] a) In the multifunctional reaction kettle, add castor oil, maleic anhydride, adipic acid, trimethylolpropane, neopentyl glycol, dimethylol propionic acid and xylene in sequence according to the weight of the formula, at a low speed N was introduced under stirring 2 , to remove the O in the reactor 2 ;

[0037] b) Heat up to 110°C, keep it warm for 0.5h, remove free water, q...

Embodiment 3

[0040] An anti-sagging APAO modified alkyd resin water-based functional coating, which consists of: 65.0 parts of APAO modified water-based alkyd resin A, 20.0 parts of silicon-modified water-based alkyd resin, 5.0 parts of propylene glycol, 0.5 parts of thickening agent, 3.0 parts of propylene glycol butyl ether, 3.0 parts of propylene glycol methyl ether acetate, 0.2 parts of defoaming agent, 0.3 parts of leveling agent, 0.2 parts of wetting agent, and 15.0 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com