A plasma jet device

A plasma and jet device technology, applied in the field of plasma, can solve the problems of lack of external connection protection and insulation device, no heat dissipation structure, difficult to use in practice, etc. The effect of ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

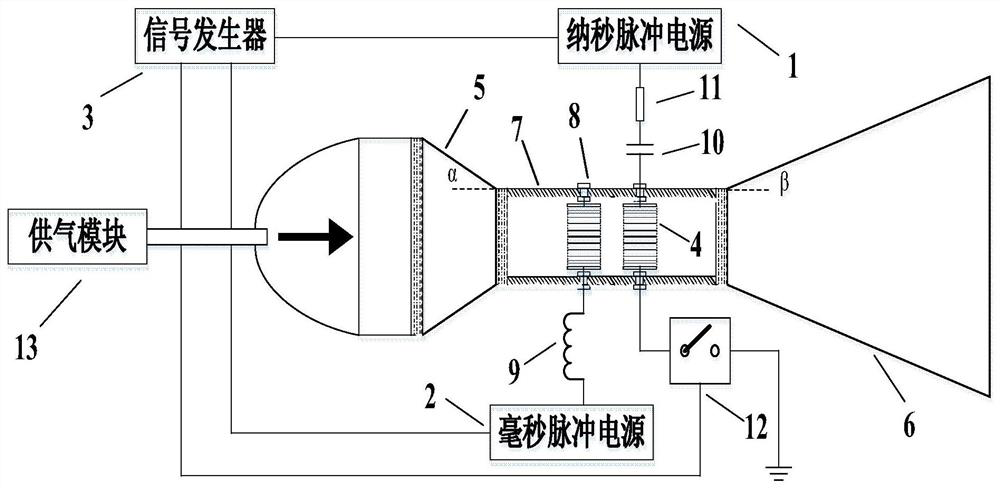

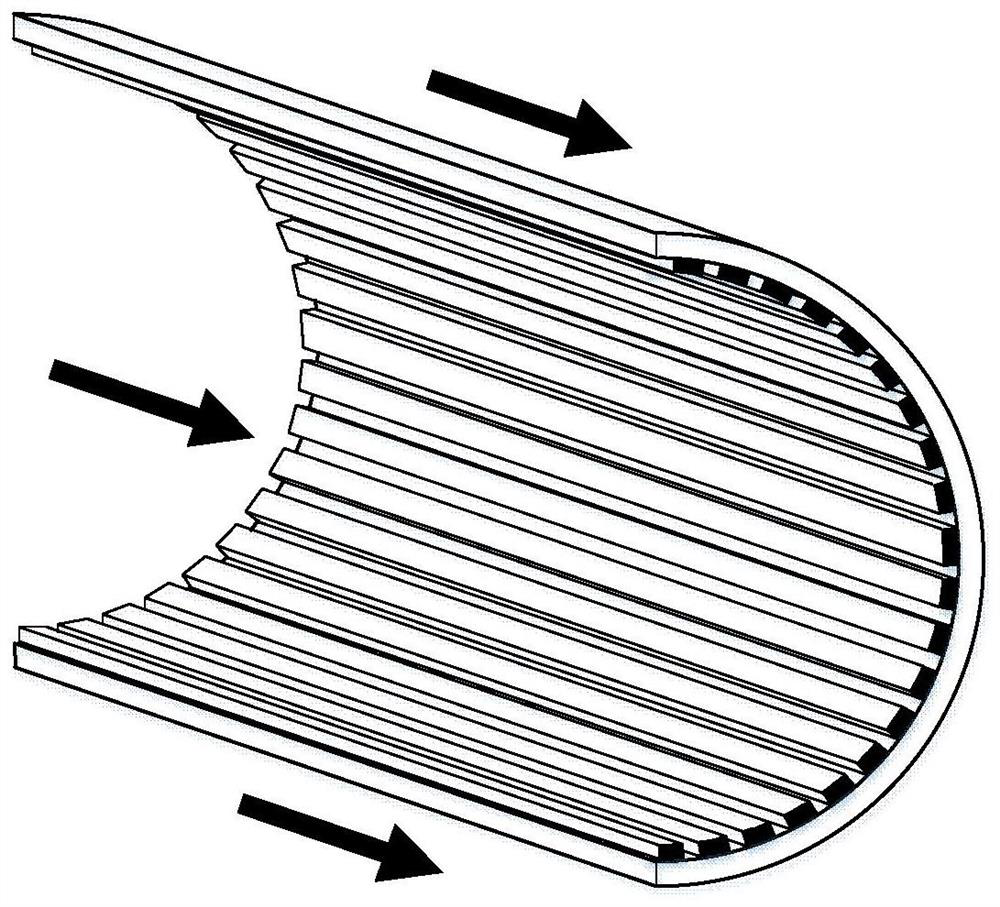

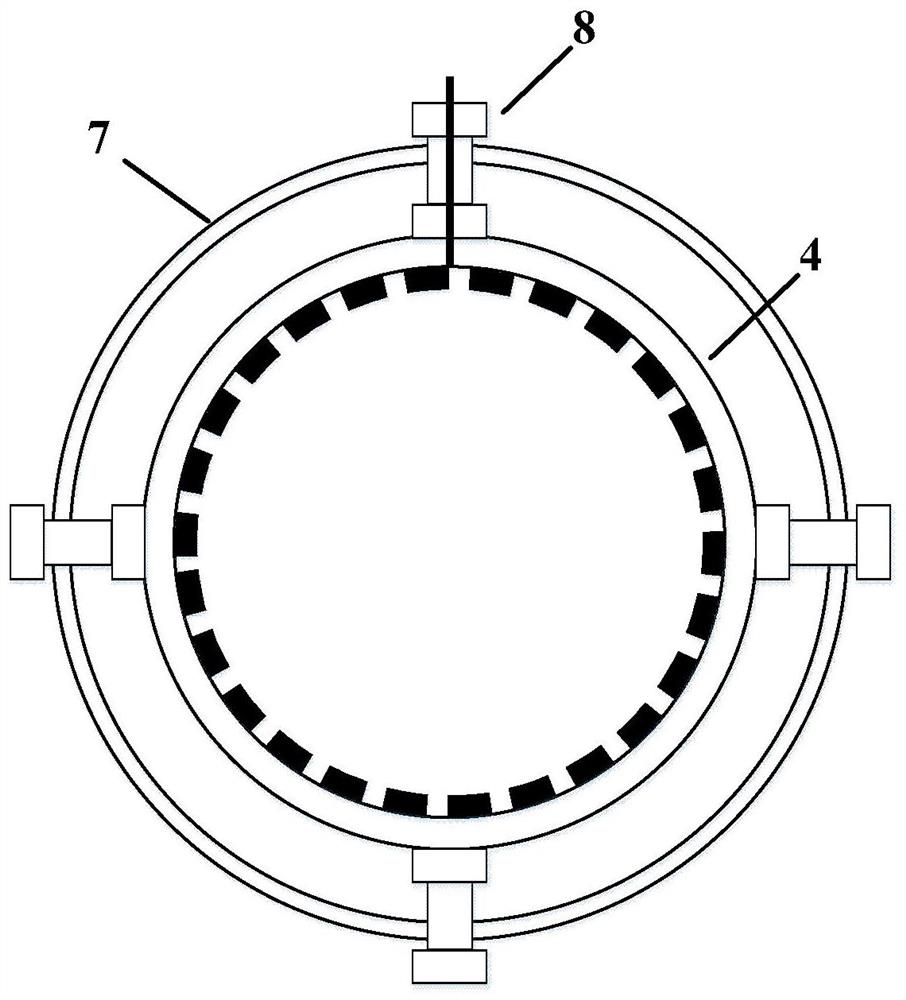

[0033] A plasma jet device such as figure 1 As shown, it includes nanosecond pulse power supply 1, millisecond pulse electric block 2, signal generator 3, toothed ring electrode 4, Laval nozzle contraction section 5, Laval nozzle expansion section 6, Laval nozzle throat 7 , flange 8, inductor 9, capacitor 10, resistor 11, high-voltage solid state switch module 12 and gas supply module 13. Among them, the schematic diagram of the toothed ring electrode and the cross-sectional view of the Laval nozzle throat are respectively shown in figure 2 and image 3 shown. Both ends of the throat of the Laval nozzle are provided with threads, and the contraction section of the Laval nozzle and the expansion section of the Laval nozzle are provided with threads that match the threads of the throat of the Laval nozzle, so as to realize the connection between the three. Connection.

[0034] In this embodiment, argon is selected as the working gas, and the gas flow rate is set to 50 L / min...

Embodiment 2

[0039] In this example, nitrogen is selected as the working gas, the gas flow rate is set to 100 L / min, and other devices are the same as those in Embodiment 1.

[0040] In this embodiment, the plasma jet generation process:

[0041] The control signal timing diagram is as follows Figure 5 As shown, adjust the pulse trigger signal through the signal generator to set the nanosecond pulse power supply to output pulse voltage in the form of pulse train, the frequency is 1kHz, the single pulse width is 200ns, the number of single-cycle pulses is 5, and the pulse interval time is 2μs. Set the trigger signal frequency of the high-voltage solid-state switch to 1kHz, turn on the solid-state switch 2 μs ahead of the nanosecond pulse power supply in timing, and close the solid-state switch with a delay of 2 μs after the end of the pulse train. After a delay of 2μs after the solid-state switch is closed, the millisecond pulse power supply outputs a pulse voltage with a frequency of 1kH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com