Ultrafine nitrogen-doped molybdenum carbide nanoparticle loaded on three-dimensional nitrogen-doped flower-shaped carbon spheres, as well as preparation method and application thereof

A nanoparticle and nitrogen-doped technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of high Mo-H bond, unfavorable hydrogen precipitation, high temperature, easy agglomeration, low transmission efficiency, etc. problem, to achieve the effect of facilitating charge transfer, reducing adsorption energy, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

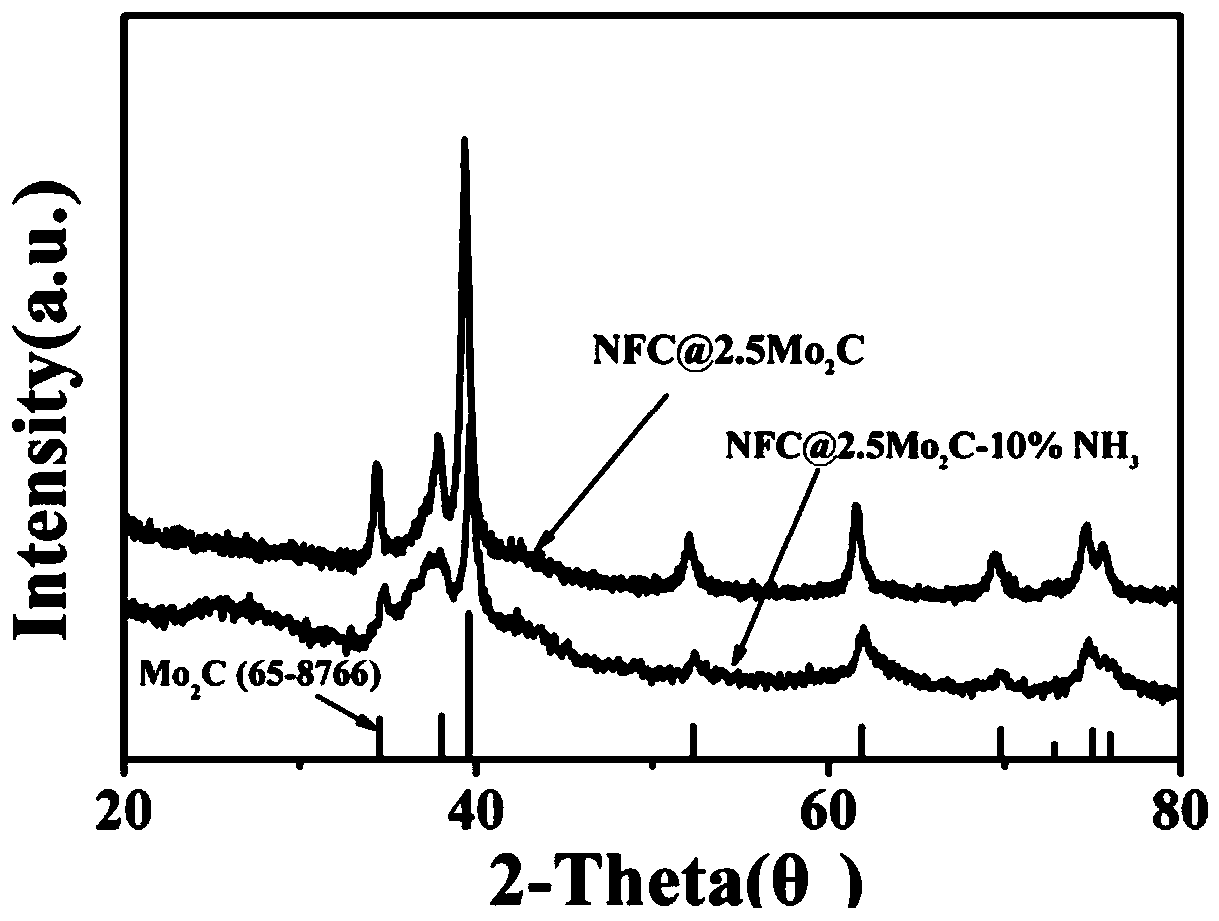

[0035] Sample preparation: Dissolve 1g of flower-shaped carbon spheres and 1g of cetyltrimethylammonium bromide in 75mL of deionized water and disperse evenly, then add 1.5g of ammonium molybdate and wait for the ammonium molybdate to dissolve and disperse evenly, then transfer to the reaction kettle , reacted at 200°C for 10 h, cooled to room temperature, filtered and washed the solution three times, and transferred to an oven at 80°C to dry the sample. Then collect the solid powder, anneal at a high temperature in an argon atmosphere, raise the temperature to 800°C at 5°C / min, keep it for 2 hours, and then cool it naturally to obtain ultrafine nitrogen-doped molybdenum carbide nanoparticles supported by three-dimensional nitrogen-doped flower-shaped carbon spheres electrocatalyst.

[0036] Electrocatalytic application: 2 mg of sample and 1 mg of conductive carbon are dissolved in 500 μL of alcohol-water mixture, and ultrasonically mixed to form a black suspension. Take 10 μL...

Embodiment 2

[0038] Sample preparation: Dissolve 1g of flower-shaped carbon spheres and 1g of cetyltrimethylammonium bromide in 75mL of deionized water and disperse evenly, then add 2.5g of ammonium molybdate and wait for the ammonium molybdate to dissolve and disperse evenly, then transfer to the reaction kettle , reacted at 200°C for 10 h, cooled to room temperature, filtered and washed the solution three times, and transferred to an oven at 80°C to dry the sample. Then collect the solid powder, anneal at a high temperature in an argon atmosphere, raise the temperature to 800°C at 5°C / min, keep it for 2 hours, and then cool it naturally to obtain ultrafine nitrogen-doped molybdenum carbide nanoparticles supported by three-dimensional nitrogen-doped flower-shaped carbon spheres electrocatalyst.

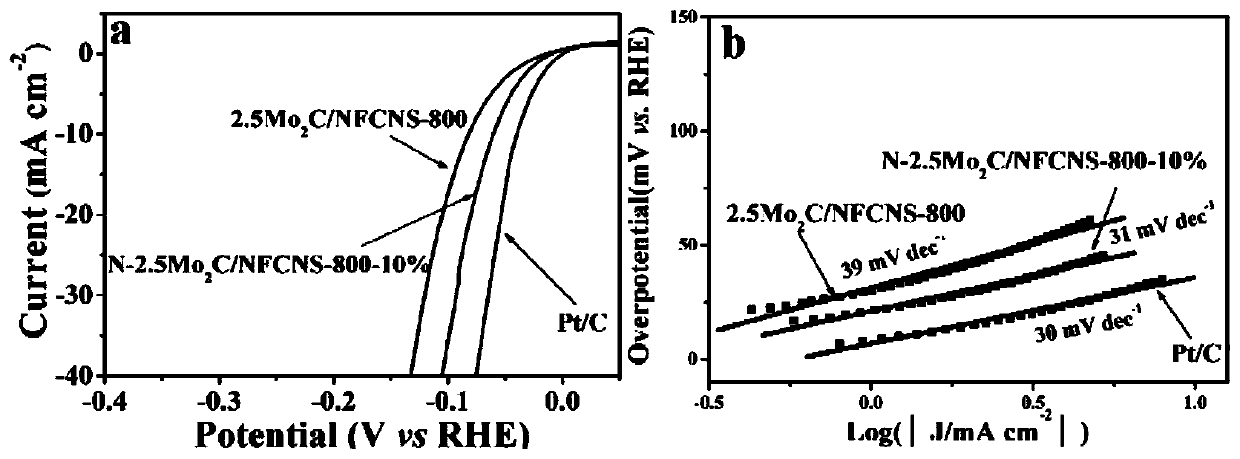

[0039] Electrocatalytic application: preparation and testing of electrodes are the same as in Example 1. The sample current density is 10mA / cm 2 , the overpotential in acidic solution is 82mV. ...

Embodiment 3

[0041] Sample preparation: Dissolve 1g of flower-shaped carbon spheres and 1g of hexadecyltrimethylammonium bromide in 75mL of deionized water and disperse evenly, then add 3.5g of ammonium molybdate and wait for the ammonium molybdate to dissolve and disperse evenly, then transfer to the reaction kettle , reacted at 200°C for 10 h, cooled to room temperature, filtered and washed the solution three times, and transferred to an oven at 80°C to dry the sample. Then collect the solid powder, anneal at a high temperature in an argon atmosphere, raise the temperature to 800°C at 5°C / min, keep it for 2 hours, and then cool it naturally to obtain ultrafine nitrogen-doped molybdenum carbide nanoparticles supported by three-dimensional nitrogen-doped flower-shaped carbon spheres electrocatalyst.

[0042] Electrocatalytic application: preparation and testing of electrodes are the same as in Example 1. The sample current density is 10mA / cm 2 , the overpotential in acidic solution is 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com