Composite microbial preparation for in-situ remediation of drain outlet of steel smelting port ditch

A composite microorganism and in-situ repair technology, applied in the field of composite microbial preparations, can solve the problems of reducing oily substances and inapplicable in-situ repair, and achieve the effects of promoting dissolution, improving sedimentation performance, and strengthening the mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

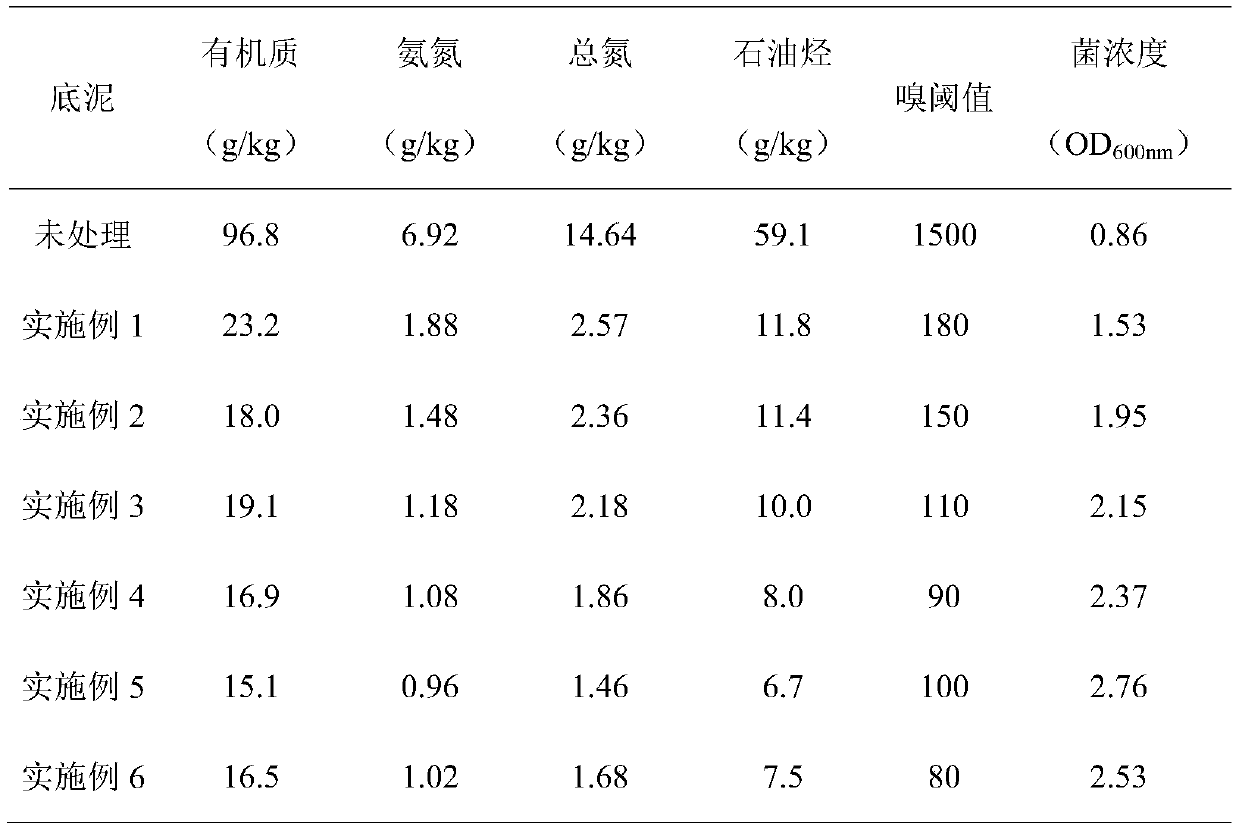

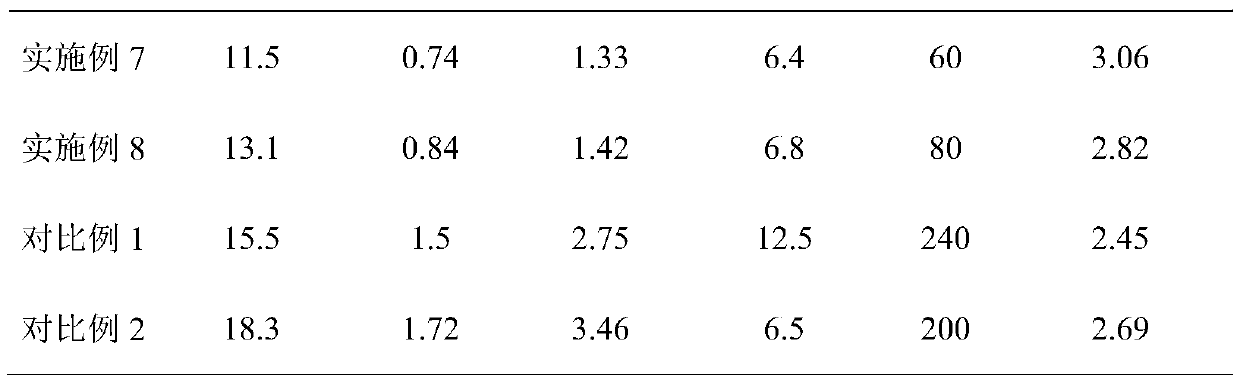

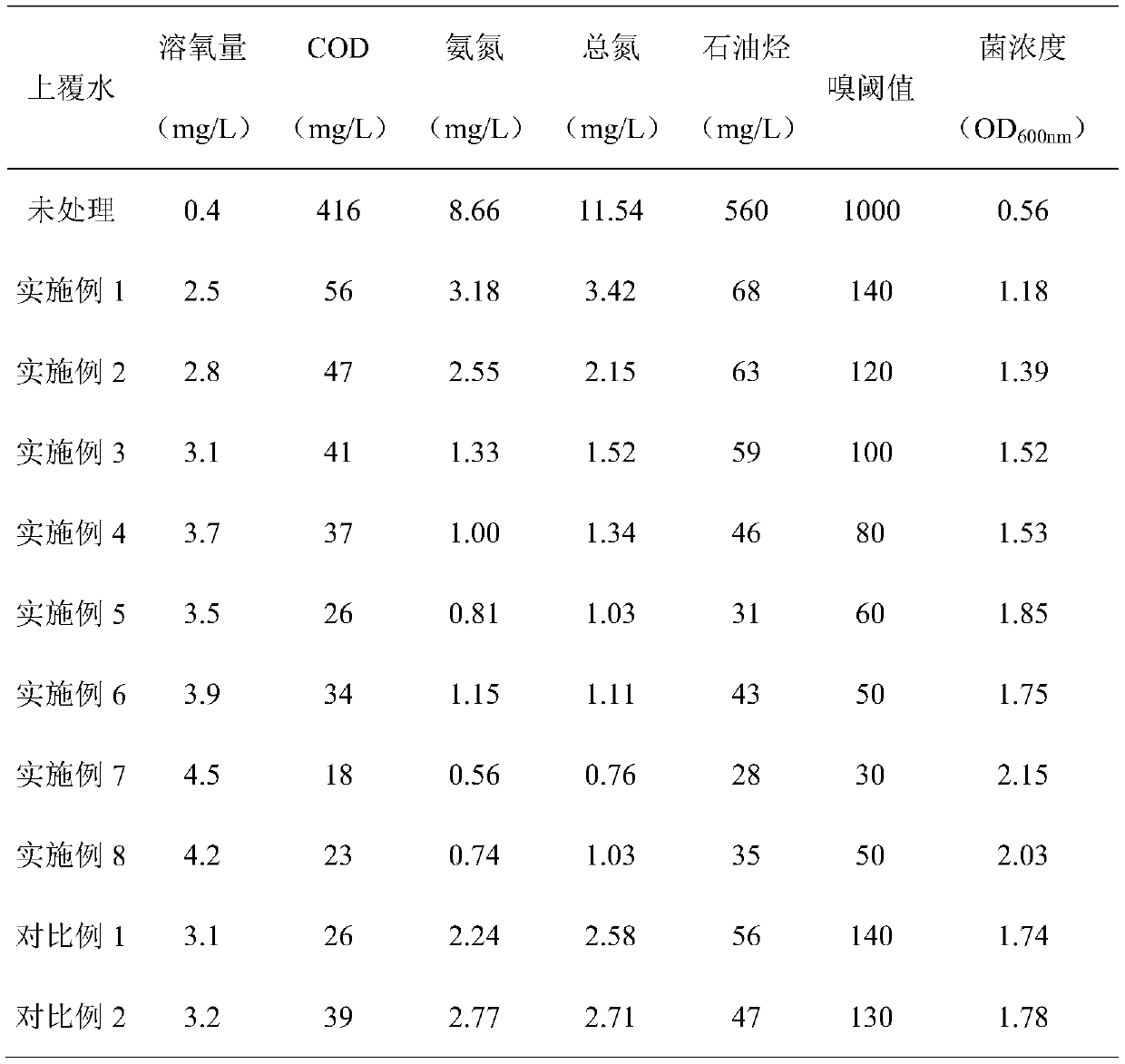

Examples

preparation example Construction

[0029] The preparation method of the modified steel slag is as follows: mix the steel slag and 2mol / L hydrochloric acid solution at a mass volume ratio of 1:1-2, stir at room temperature for 4-6 hours to obtain porous steel slag, then drain the porous steel slag, and use deionized Wash with water until neutral, grind and magnetically separate to obtain modified steel slag from which magnetic metals have been removed.

[0030] The preparation method of the modified steel slag loaded with microorganisms: adding the mixed bacteria powder and modified steel slag into the fermentation medium, shaking and culturing at room temperature at 100-150 rpm for 6-8 hours, freeze-drying until the water content is lower than 6%, and obtaining the modified microorganism-loaded steel slag. Steel slag;

[0031] It has been found through experiments that when the parameters of the above preparation method are reasonably adjusted within the protection scope of the present application, the performa...

Embodiment 1

[0033] A compound microbial preparation for in-situ restoration of the sewage outlet of the Smelting Ganggang Canal, comprising: 20 parts of Aspergillus niger, 15 parts of Monascus, 40 parts of Nitrobacter victorii, 12 parts of Thiobacillus denitrificans, 10 parts of anaerobic Ammonia oxidizing bacteria, 15 parts of Pseudomonas stutzeri, 15 parts of Acinetobacter venezii, 28 parts of Bacillus licheniformis, 155 parts of carrier, and the carrier is made of modified steel slag. Its preparation method comprises the following steps:

[0034] S1. Preparation of microbial fermentation broth: respectively cultivate Aspergillus niger, Monascus, Nitrobacter victoria, Thiobacillus denitrification, anammox bacteria, Pseudomonas stutzeri, Acinetobacter venezii and Bacillus licheniformis to live bacteria Number greater than 2×10 9 CFU / mL, freeze-dried to obtain the seed powder of various strains, and then uniformly mixed the seed powder according to the proportion by mass to obtain the mi...

Embodiment 2

[0038] Example 2 is basically the same as Example 1, the difference being that the carrier is made of modified steel slag and coconut shell at a mass ratio of 12:1. Its preparation method comprises the following steps:

[0039] S1. Preparation of microbial fermentation broth: respectively cultivate Aspergillus niger, Monascus, Nitrobacter victoria, Thiobacillus denitrification, anammox bacteria, Pseudomonas stutzeri, Acinetobacter venezii and Bacillus licheniformis to live bacteria Number greater than 2×10 9 CFU / mL, freeze-dried to obtain the seed powder of various strains, and then uniformly mixed the seed powder according to the proportion by mass to obtain the mixed powder;

[0040] S2. Add the mixed bacteria powder and modified steel slag to the fermentation medium, shake and cultivate at room temperature at 100-150 rpm for 6-8 hours, freeze-dry until the water content is lower than 6%, and obtain the modified steel slag loaded with microorganisms;

[0041] S3. Take the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com