Gene for encoding LsGAD (Lactobacillus senmaizukei glutamic acid decarboxylase), recombinant bacterium and Kombucha fermentation viable bacteria preparation

A technology of glutamic acid decarboxylase and recombinant engineering bacteria, which is applied in genetic engineering, fermentation, plant gene improvement, etc., can solve the problems of insufficient GABA health care efficacy and low production of GABA, and achieve good industrialization prospects and production The effect of short cycle and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

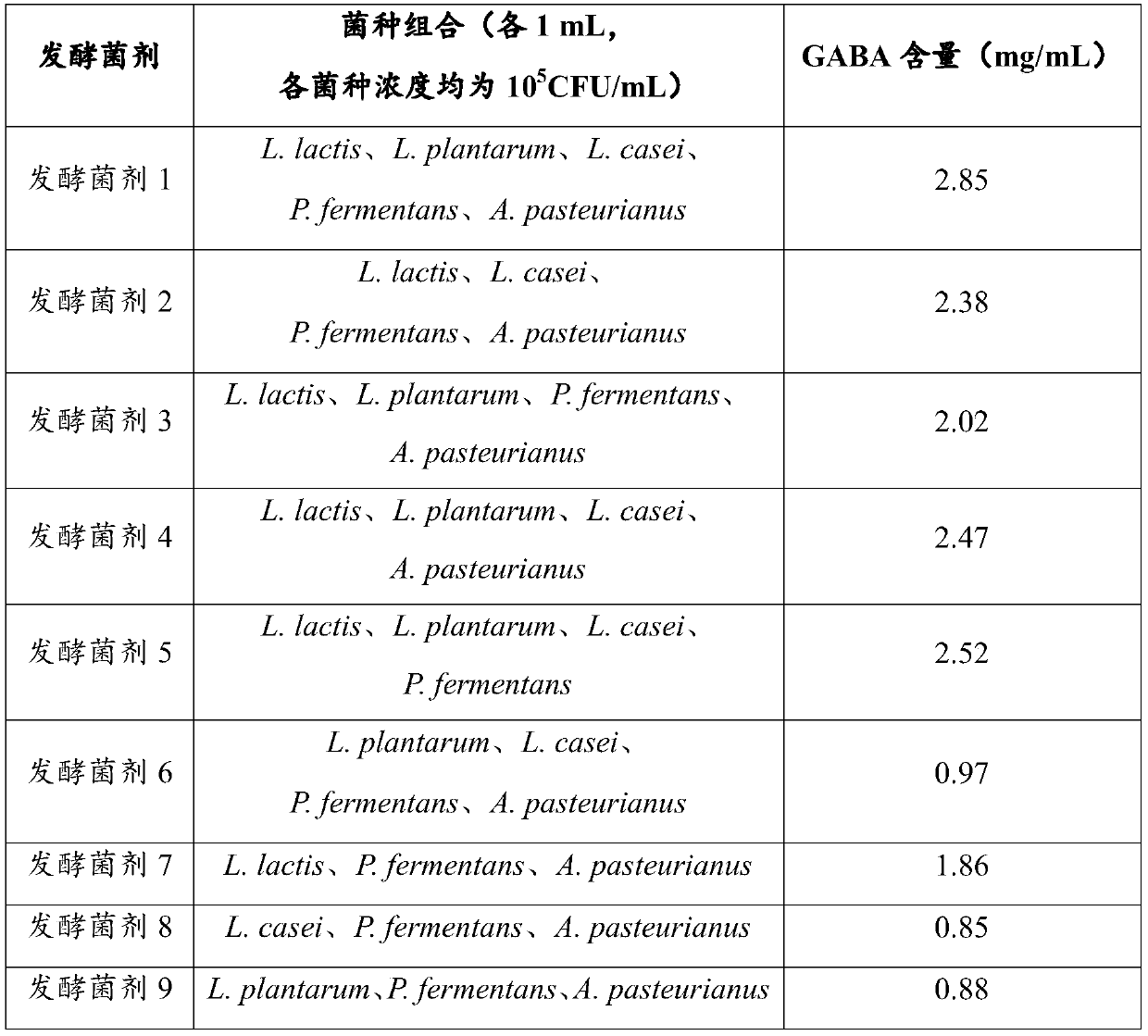

Examples

Embodiment 1

[0020] Example 1 Obtain the gene encoding glutamic acid decarboxylase of the present invention and construct recombinant engineering bacteria

[0021] The present invention takes a novel glutamic acid decarboxylase gene (LsGAD gene) excavated from the genome of Lactobacillus senmaizukei certified by GRAS as the target gene, and performs codon optimization with reference to the codon usage frequency table of Lactococcus lactis MG1363. After the whole gene synthesis, the engineering bacteria of Lactococcus lactis capable of high-yielding γ-aminobutyric acid were successfully constructed with the help of the food-grade lactic acid bacteria expression plasmid pNZ8149. Wherein, the nucleotide sequence of the gene encoding glutamic acid decarboxylase after codon optimization of the present invention is shown in SEQ ID NO.1; the amino acid sequence of the glutamic acid decarboxylase LsGAD is shown in SEQ ID NO.2 .

[0022] Construction of the recombinant vector: The glutamic acid de...

Embodiment 2

[0025] The preparation of embodiment 2 Kombucha

[0026] 2.1 Preparation of fermentation base liquid: Take 10g of black tea leaves, 5g of skimmed milk powder, 5g of monosodium glutamate and 100g of sucrose, mix well with 1000mL of tap water, boil for 10min, filter with 8 layers of medical gauze to obtain fermentation base liquid A, and quickly cool to room temperature, Then add nisin (nisin) mother solution to a final concentration of 1ng / mL to obtain fermentation base solution B, place it in a sterile glass bottle, wrap the mouth of the bottle with 8 layers of gauze and kraft paper to prevent bacterial contamination, and store it for future use;

[0027] 2.2 Strain pretreatment

[0028] (1) Preparation of Lactococcus lactis engineering bacteria (prepared in Example 1) seed solution

[0029] Inoculate Lactococcus lactis engineered bacteria into M17 solid medium, culture at 30°C for 48 hours to obtain a single colony, pick a single colony and inoculate it into 100mL M17 liquid...

Embodiment 3

[0058] Prepare kombucha according to the method of above-mentioned embodiment 2, and the difference with embodiment 2 is only: adopt fermentation agent 1 to carry out kombucha fermentation, wherein, the concentration of 5 kinds of strains in fermentation agent 1 is 10 6 CFU / mL; fermentation time is 8 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com