Preparation method of defect-state titanium oxide-aluminum oxide-graphene ceramic electrode

A ceramic electrode, titanium oxide technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of poor post-processing, low mechanical strength, high preparation cost, and improve toughness and preparation cost. The effect of low, wide potential window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The following steps are taken to prepare defective titanium oxide-alumina-graphene ceramic electrodes:

[0046] (1) According to the material ratio (weight ratio) of 65:25:10:2:0.025, mix aluminum oxide, titanium oxide, zinc, zinc oxide and graphene solid powder (wherein aluminum oxide, titanium oxide, zinc, zinc oxide powder Particle diameters are 3μm, 5μm, 200nm, 20nm) to obtain a homogeneous mixture;

[0047] (2) Mix the above mixture with a polyacrylamide binder with a mass fraction of 0.5% and ball mill it for 6 hours to make ceramic powder, then granulate the obtained ceramic powder, and control the moisture content of the particles to 5% (weight ratio) , the particle size is 40-80 mesh;

[0048] (3) At 1000kg / m 2 The ceramic particles are made into a ceramic slab with a thickness of 5mm in the mold under a certain pressure;

[0049] (4) heat-treat the ceramic base plate at 80° C. for 24 hours to remove moisture and organic binder in the base;

[0050] (5) Sin...

Embodiment 2

[0055] Specific application method of defective titanium oxide-alumina-graphene ceramic electrode

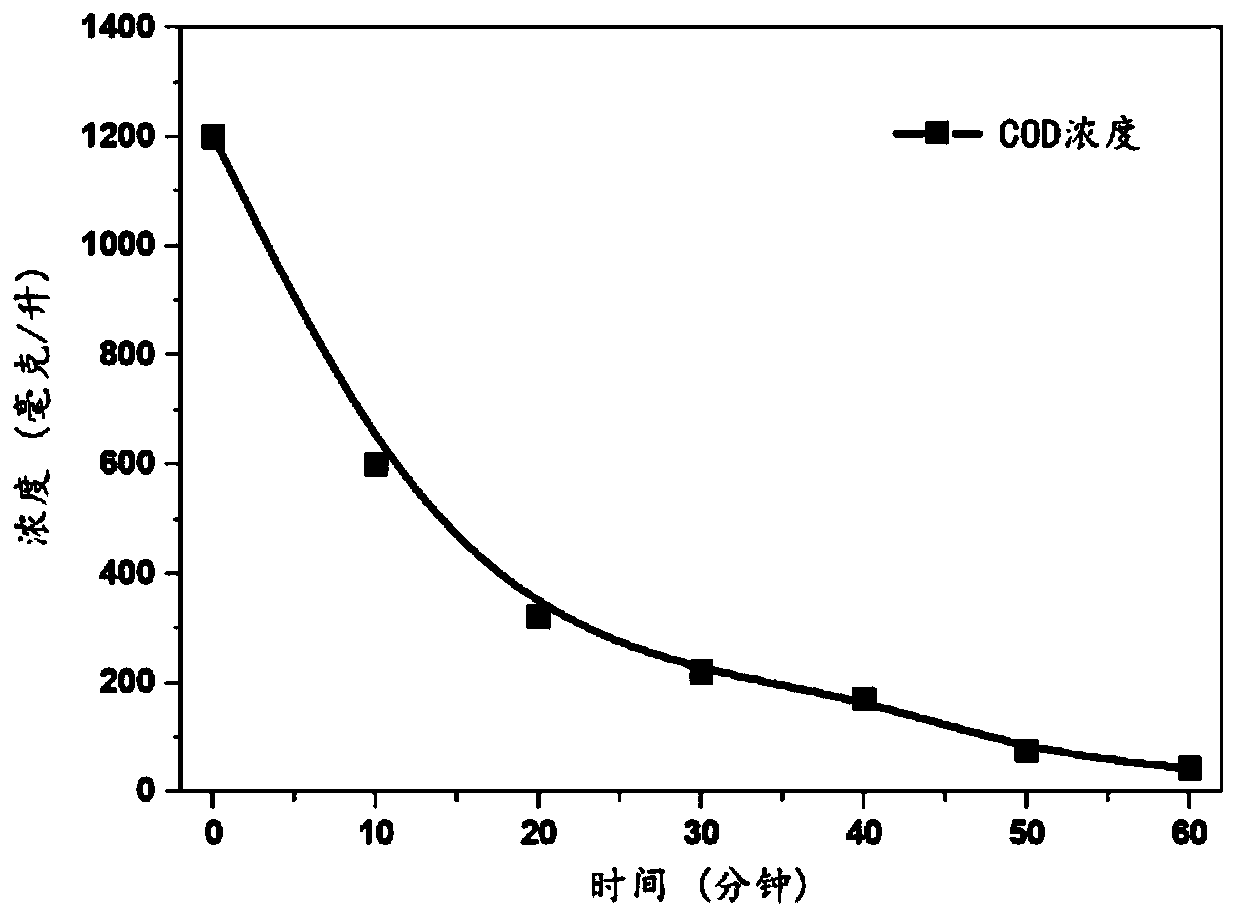

[0056] Taking the treatment of alkali slag wastewater with defective titanium oxide-alumina-graphene ceramic electrodes as an example, take 1L of alkali residue wastewater from a chemical plant and place it in a flat electrocatalytic reactor, and use defective titanium oxide-alumina-graphene The ceramic electrode is used as the anode, and the stainless steel electrode is used as the cathode. The distance between the cathode and the anode is controlled to be 10mm, and the current density is 20mA / cm 2 , DC pulse electrolytic treatment of alkali slag wastewater for 60 minutes, sampling and analysis of COD concentration in water, the results are as follows image 3 As shown, the COD removal rate is 95.8%.

Embodiment 3

[0058] Another specific method of using the defective titanium oxide-alumina-graphene ceramic electrode

[0059] Taking the treatment of aniline wastewater with defective titanium oxide-alumina-graphene ceramic electrodes as an example, take 500mL of aniline wastewater from a chemical plant and place it in a flat electrocatalytic reactor, and use defective titanium oxide-alumina-graphene ceramic electrodes As the anode, the stainless steel electrode is the cathode, the distance between the cathode and the anode is controlled to be 15mm, and the current density is 40mA / cm 2 , DC pulse electrolytic treatment of aniline wastewater for 60 minutes, sampling and analysis of COD and ammonia nitrogen concentration in the water, the results are as follows Figure 4 As shown, the removal rate of COD is 96.2%, and the removal rate of ammonia nitrogen is 92.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com