Fe-Co-S nanosheet material and preparation method thereof and application

A technology of fe-co-s and nanosheets, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of rate performance limitation, low conductivity, etc., and achieve high energy density and Power density, simple preparation method, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

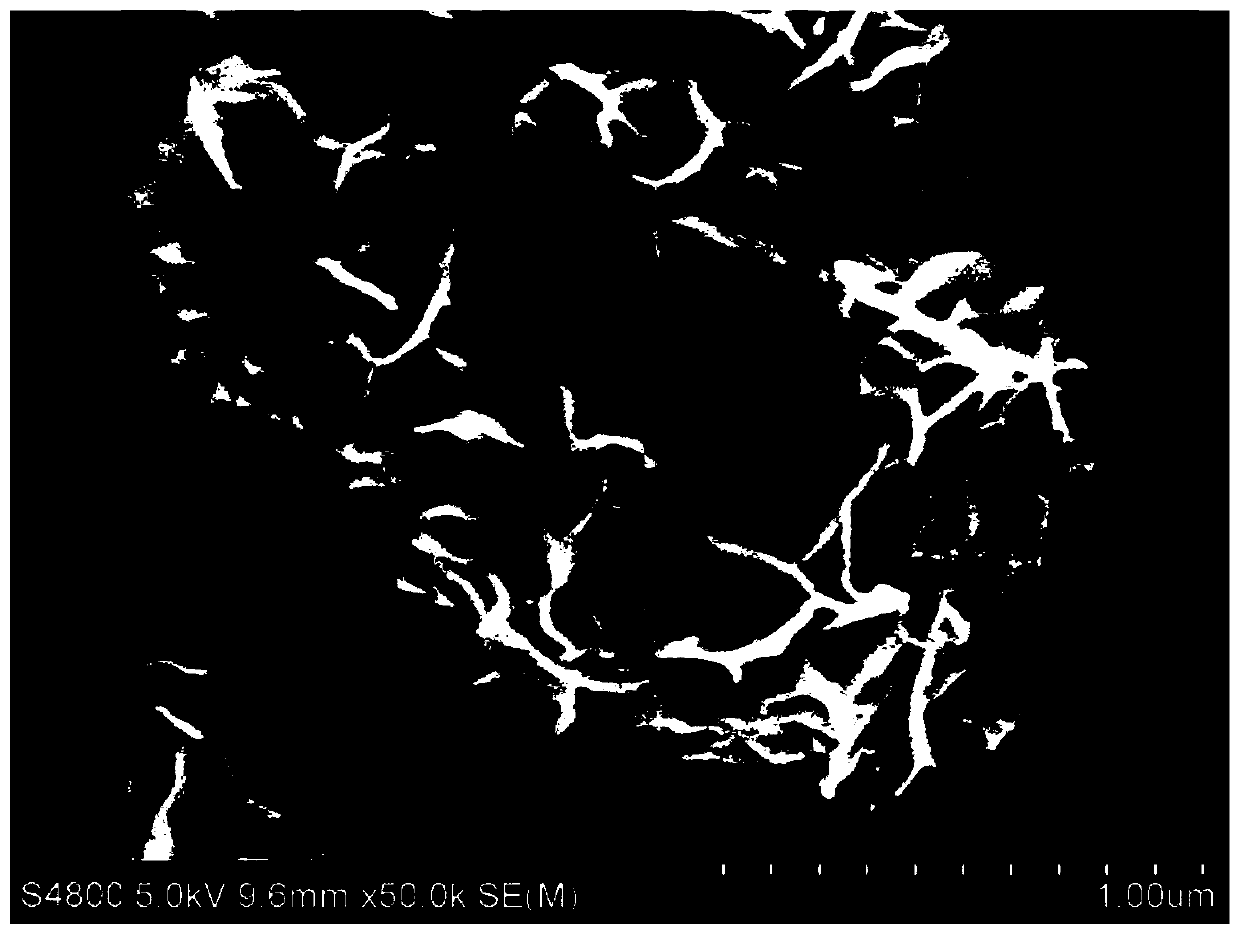

[0033] A preparation method of Fe-Co-S nanosheet material, comprising the following steps:

[0034] 2mmol Co(NO 3 ) 2 ·6H 2 O, 0.8mmol Fe(NO 3 ) 3 9H 2 O, 8mmol NH 4 F. Dissolve 4mmol of urea in 40mL of water, stir evenly with magnetic force, add 0.1g of thiourea to it and quickly transfer to 80mL polytetrafluoroethylene-lined stainless steel autoclave for one-step hydrothermal reaction, the temperature of hydrothermal reaction is 120℃ , The hydrothermal reaction time is 8h; the sample after hydroheating is taken out and cooled, then centrifuged, washed, and vacuum-dried at 60°C for 12h to obtain a powder. After the active material is ground, it is evenly mixed with carbon black and polytetrafluoroethylene in a mass ratio of 8:1:1, pressed onto a nickel foam sheet (1cm×1cm), and dried in an oven at 60°C for 12h to obtain Fe-Co-S working electrode (note FCS-1).

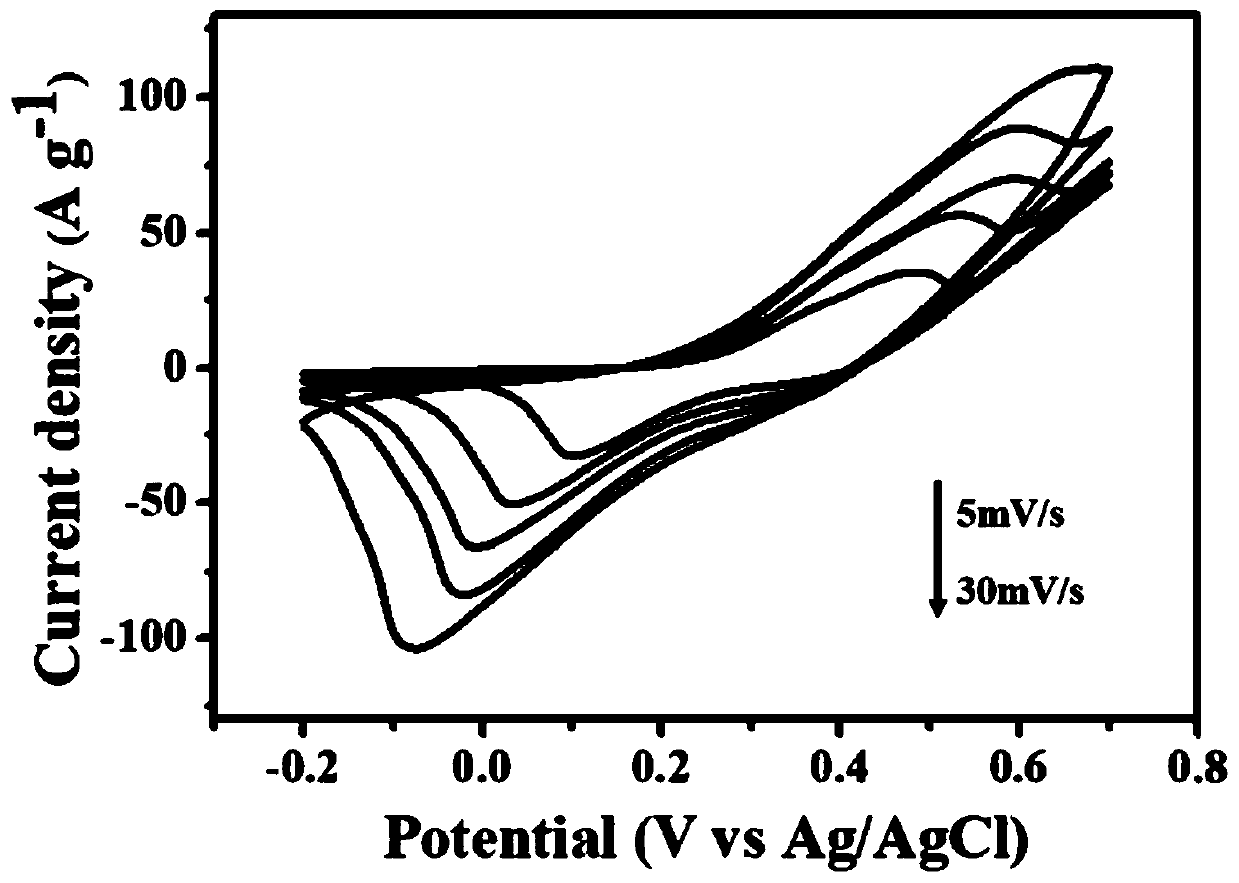

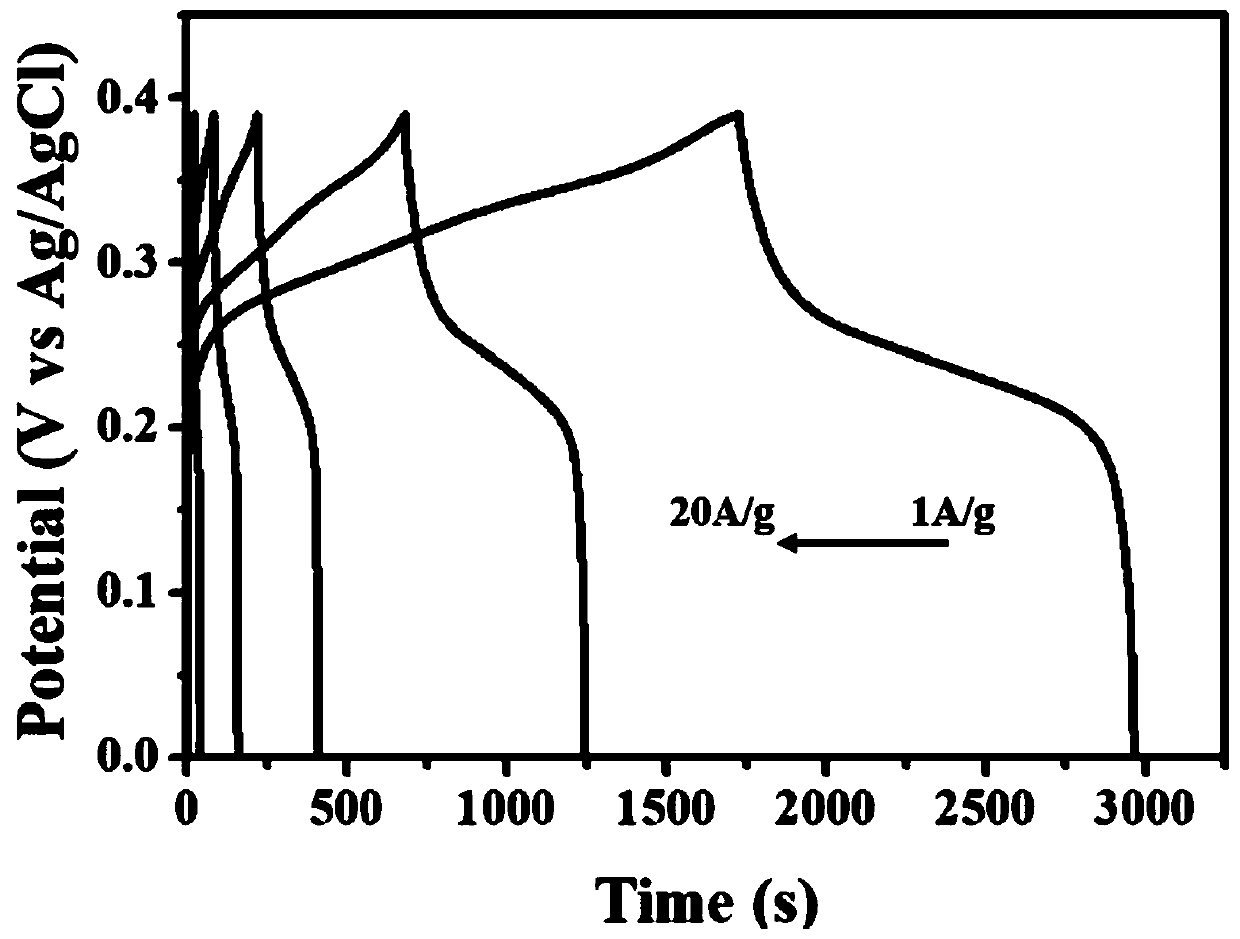

[0035]Jing Chenhua CHI760e electrochemical workstation adopts the method of cyclic voltammetry and constant ...

Embodiment 2

[0045] A preparation method of Fe-Co-S nanosheet material, comprising the following steps:

[0046] 2mmol Co(NO 3 ) 2 ·6H 2 O, 1mmol Fe(NO 3 ) 3 9H 2 O, 8mmol NH 4 F. Dissolve 4mmol of urea in 40mL of water, stir evenly with magnetic force, add 0.5g of thiourea to it and quickly transfer to 80mL polytetrafluoroethylene-lined stainless steel autoclave for one-step hydrothermal reaction, the temperature of hydrothermal reaction is 120℃ , The hydrothermal reaction time is 8h; the sample after hydroheating is taken out and cooled, then centrifuged, washed, and vacuum-dried at 60°C for 12h to obtain a powder. After the active material is ground, it is evenly mixed with carbon black and polytetrafluoroethylene in a mass ratio of 8:1:1, pressed onto a nickel foam sheet (1cm×1cm), and dried in an oven at 60°C for 12h to obtain Fe-Co-S working electrode (note FCS-2).

[0047] Jingchenhua CHI760e electrochemical workstation adopts cyclic voltammetry and constant current charge a...

Embodiment 3

[0052] A preparation method of Fe-Co-S nanosheet material, comprising the following steps:

[0053] 2mmol Co(NO 3 ) 2 ·6H 2 O, 1mmol Fe(NO 3 ) 3 9H 2 O, 8mmol NH 4 F. Dissolve 4mmol of urea in 40mL of water, stir evenly with magnetic force, add 0.5g of thiourea to it and quickly transfer to 80mL polytetrafluoroethylene-lined stainless steel autoclave for one-step hydrothermal reaction, the temperature of hydrothermal reaction is 140℃ , The hydrothermal reaction time is 8h; the sample after hydroheating is taken out and cooled, then centrifuged, washed, and vacuum-dried at 60°C for 12h to obtain a powder. After the active material is ground, it is evenly mixed with carbon black and polytetrafluoroethylene in a mass ratio of 8:1:1, pressed onto a nickel foam sheet (1cm×1cm), and dried in an oven at 60°C for 12h to obtain Fe-Co-S working electrode (note FCS-3).

[0054] Jingchenhua CHI760e electrochemical workstation adopts cyclic voltammetry and constant current charge a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com