Method for producing food-grade disodium hydrogen phosphate by using wet-process dilute phosphoric acid

A technology of disodium hydrogen phosphate and dilute phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

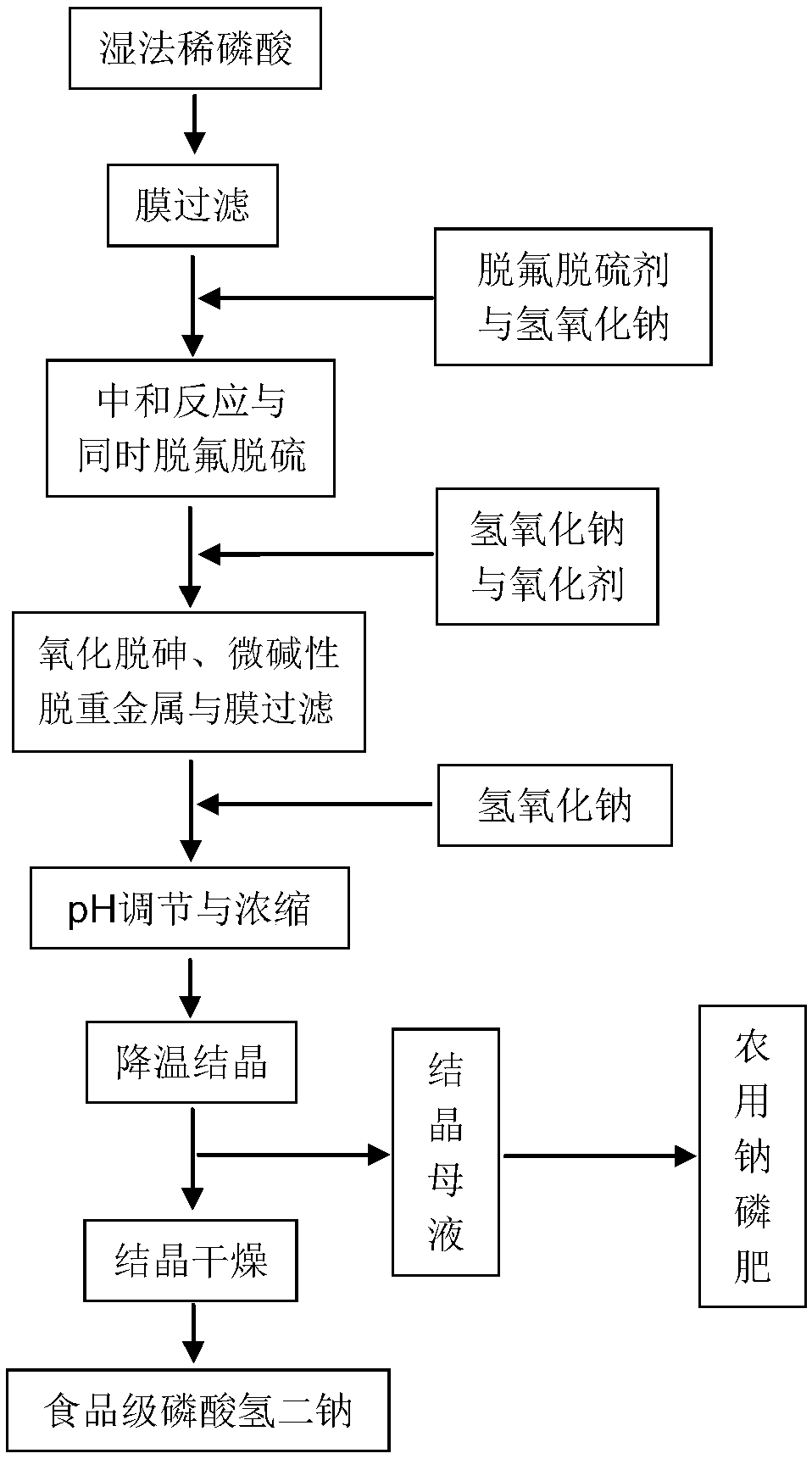

Image

Examples

Embodiment 1

[0036] A kind of method that utilizes wet method dilute phosphoric acid to manufacture food grade disodium hydrogen phosphate, its step is:

[0037] (1) Membrane filtration: Take 1.85 kg of wet-process dilute phosphoric acid (aqueous solution) with a phosphoric acid content of 40% (mass fraction), a sulfate radical content of 1.5% (mass fraction) and a fluoride ion content of 0.5% (mass fraction) in an acid-resistant In the container, the membrane material is silicon carbide, the membrane pore is 0.04μm, and the membrane module is a briquette-type inner tubular membrane for precise filtration to separate pigment particles, suspended solids and solid particles, etc., to obtain precision filtration. Wet-process dilute phosphoric acid for use.

[0038] (2) Neutralization reaction and simultaneous defluorination and desulfurization: Take the precision-filtered wet-process dilute phosphoric acid obtained in step (1) in an acid-resistant container, and add barium carbonate with a ma...

Embodiment 2

[0045] A kind of method that utilizes wet method dilute phosphoric acid to manufacture food grade disodium hydrogen phosphate, its step is:

[0046] (1) Membrane filtration: Take 10.19kg of wet-process dilute phosphoric acid (aqueous solution) whose main components are phosphoric acid content 43% (mass fraction), sulfate radical content 1.6% (mass fraction) and fluoride ion content 0.6% (mass fraction) in an acid-resistant container , using microporous membrane equipment with membrane material of silicon carbide, membrane pores of 0.1 μm, and membrane components in the form of briquette-type inner tubular membranes to precisely filter it, separate pigment particles, suspended solids and solid particles, etc., and obtain precision-filtered wet French dilute phosphoric acid for use.

[0047] (2) Neutralization reaction and simultaneous defluorination and desulfurization: Take the precision-filtered wet-process dilute phosphoric acid obtained in step (1) in an acid-resistant cont...

Embodiment 3

[0054] A kind of method that utilizes wet method dilute phosphoric acid to manufacture food grade disodium hydrogen phosphate, its step is:

[0055] (1) Membrane filtration: Take 4.25 kg of wet-process dilute phosphoric acid (aqueous solution) with a phosphoric acid content of 37% (mass fraction), a sulfate radical content of 1.4% (mass fraction) and a fluoride ion content of 0.4% (mass fraction) in an acid-resistant In the container, the membrane material is silicon carbide, the membrane pore is 0.04μm, and the membrane module is a briquette-type inner tubular membrane for precise filtration to separate pigment particles, suspended solids and solid particles, etc., to obtain precision filtration. Wet-process dilute phosphoric acid for use.

[0056] (2) Neutralization reaction and simultaneous defluorination and desulfurization: Take the precision-filtered wet-process dilute phosphoric acid obtained in step (1) in an acid-resistant container, and add barium carbonate with a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com