Molybdenum disulfide nano-sheet material preparation method

A molybdenum disulfide and nanosheet technology is applied in the field of preparation of molybdenum disulfide nanosheet materials, which can solve the problems that lithium ions are difficult to completely clean, controllable mass production is difficult to achieve, and product quality is not uniform, and it is easy to intelligentize Control, improve the effect of intercalation, promote the effect of intercalation and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

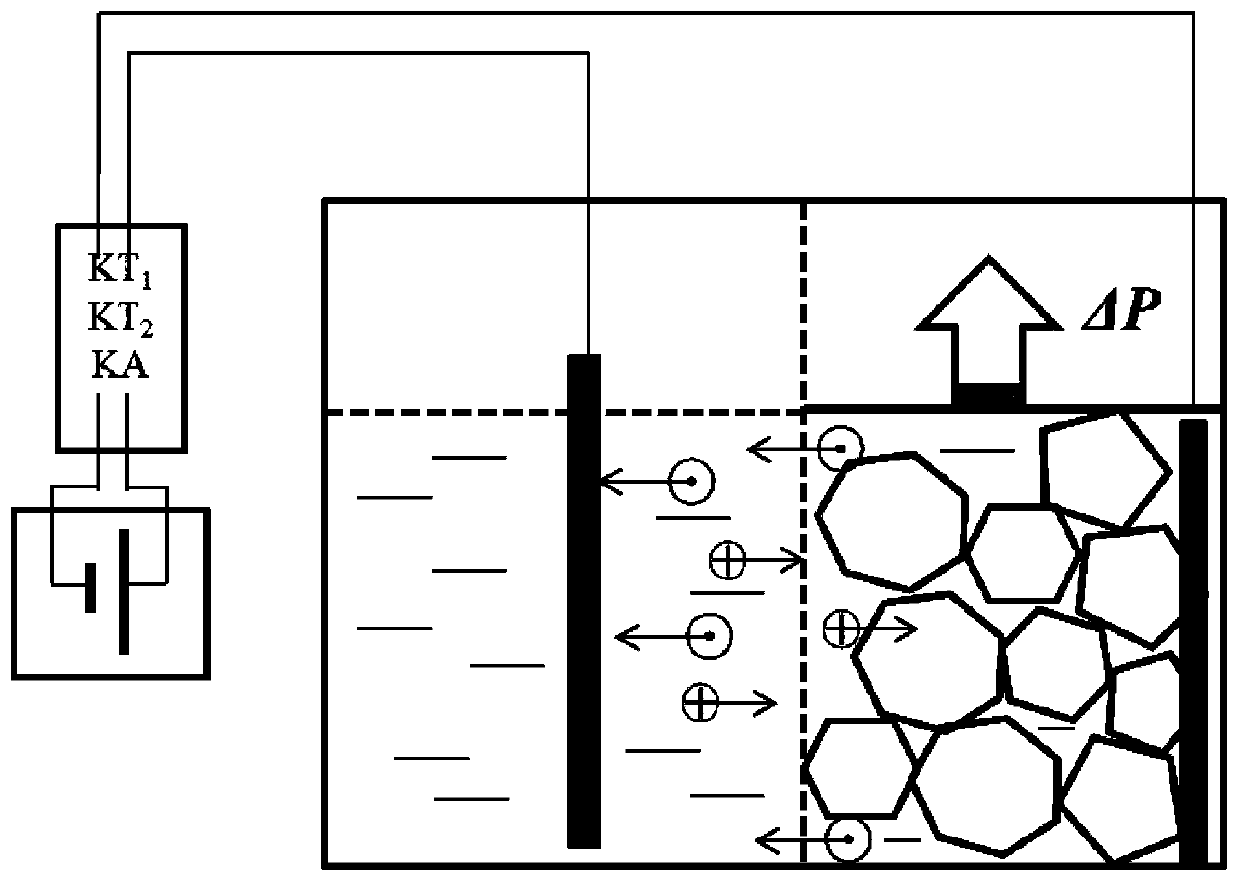

[0042]Use tetrabutylammonium bisulfate as the electrolyte and deionized water as the solvent to prepare a 5 mg / mL electrolyte solution. Take 10g of molybdenum disulfide powder (800 mesh), add 0.25g of polyvinylpyrrolidone, and then add 5mL of electrolyte solution, stir evenly, and use it as molybdenum disulfide parent material. Titanium plates were used as cathode and anode electrode materials, and the electrode spacing was set to 5 cm. A 36V DC regulated power supply is used, and the positive and negative poles are applied to the anode and cathode respectively. The anode and the cathode are vertically inserted into the electrolyte solution and the molybdenum disulfide parent material, respectively. The anode chamber and the cathode chamber are separated by a homogeneous cation exchange membrane. The liquid level of the electrolyte solution in the anode chamber is slightly higher than the upper surface of the molybdenum disulfide parent material. When the anode is inserted ...

Embodiment 2

[0044] Use tetrabutylammonium bromide as electrolyte and deionized water as solvent to prepare 7.5 mg / kg electrolyte solution. Take 10g of molybdenum disulfide powder (800 mesh), add 0.25g of xanthan gum, and then add 5mL of electrolyte solution, stir evenly, and use it as molybdenum disulfide parent material. Tungsten plates with an anti-oxidation coating are used as the cathode and anode electrode materials, and the electrode spacing is set to 5 cm. A 24V DC regulated power supply is used, and the positive and negative poles are applied to the anode and cathode respectively. The anode and the cathode are vertically inserted into the electrolyte solution and the molybdenum disulfide parent material, respectively. The anode chamber and the cathode chamber are separated by a homogeneous cation exchange membrane. The liquid level of the electrolyte solution in the anode chamber is slightly higher than the upper surface of the molybdenum disulfide parent material. When the ano...

Embodiment 3

[0046] Use dodecyltrimethylammonium bromide as the electrolyte and deionized water as the solvent to prepare a 2 mg / m electrolyte solution. Take 10g of molybdenum disulfide powder (800 mesh), add 0.25g of polyvinylpyrrolidone, and then add 5mL of electrolyte solution, stir evenly, and use it as molybdenum disulfide parent material. A nickel plate with an anti-oxidation coating was used as the cathode and anode electrode materials, and the electrode spacing was set to 5 cm. A 24V DC regulated power supply is used, and the positive and negative poles are applied to the anode and cathode respectively. The anode and the cathode are vertically inserted into the electrolyte solution and the molybdenum disulfide parent material, respectively. The anode chamber and the cathode chamber are separated by a homogeneous cation exchange membrane. The liquid level of the electrolyte solution in the anode chamber is slightly higher than the upper surface of the molybdenum disulfide parent m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com