Thioformamide, and preparation method and application thereof

A thioformamide and formamide technology, applied in the direction of organic chemistry and the like, can solve the problems of high consumption of raw materials, high price of tetrahydrofuran, low yield, etc., and the pressure and temperature conditions are easy to achieve, the preparation process is safe and controllable, and the preparation simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The first aspect of the present invention provides the preparation method of thioformamide, it may further comprise the steps:

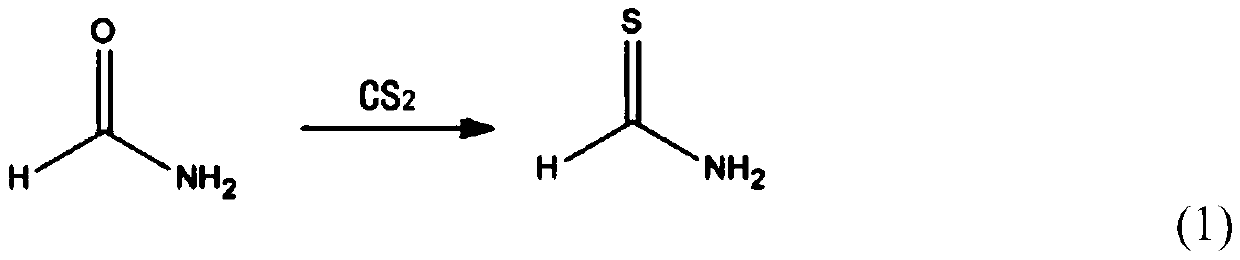

[0019] Using carbon disulfide and formamide as raw materials, under the catalysis of an organic base, react for 6-8 hours under the conditions of a pressure of 3-5 MPa and a temperature of 140-160°C to generate thioformamide, as shown in the following formula (1) Show.

[0020]

[0021] Preferably, the reaction process is carried out in an autoclave. The reaction pressure of the present invention is 3-5 MPa, and the reaction can be carried out under low pressure conditions without expensive high-pressure equipment. The requirements for equipment are relatively low, and the reaction process is safe and controllable.

[0022] The post-processing of the present invention is simple, and the product is easy to separate. Specifically, after the reaction is completed, the autoclave is cooled to below 20° C., and the generated carbon dioxide gas is...

Embodiment 1

[0029] In a 2000ml autoclave (design pressure is 10MPa) equipped with agitator, inner coil condenser, pressure gauge and thermometer, add a certain amount of sodium methoxide, cover the lid of the kettle and do a safety inspection according to regulations. After replacing with nitrogen, add 760g of carbon disulfide and 90g of formamide, after the addition of the raw materials, fill the tank with nitrogen to raise the pressure to 3MPa, and close the nitrogen inlet valve. The temperature was raised to 140°C at a uniform rate within 1 hour for reaction, and the pressure of the kettle was kept at 3-5 MPa. Insulate and react at a temperature of 140-160° C. for 6-8 hours to generate thioformamide. Stop heating, pass cooling water through the inner coil to cool down to below 20°C, open the exhaust pipe to release the pressure to normal pressure, discharge the generated carbon dioxide gas, close the exhaust pipe, and pressurize the reaction liquid with nitrogen gas from the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com