Metal antirust paint with modified steel slag-based pigment and filler replacing iron oxide red, and preparation method

A steel slag-based paint and metal anti-rust technology, which is applied in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of expensive filling pigments, and achieve the effects of enhancing market competitiveness, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

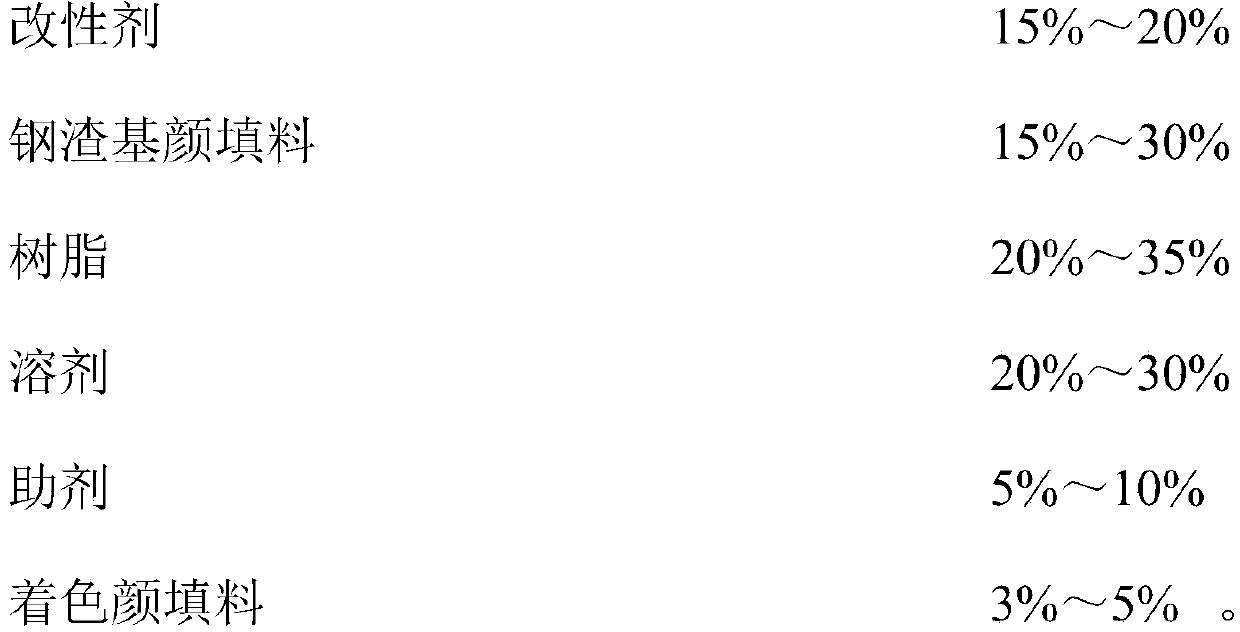

[0024] Modified steel slag-based pigments and fillers replace iron red metal antirust coatings, consisting of the following substances by weight percentage:

[0025]

[0026] The selected modifier is a mixed solution of ferric chloride and aluminum chloride with a pH value of 6; the steel slag-based pigment and filler is 400 mesh steel slag fine powder; the resin is a mixture of epoxy resin and alkyd resin; the solvent is ethyl ester; It is a mixture of wetting agent, dispersant, defoamer, thickener, leveling agent and anti-settling agent; The foaming agent is an amide, the thickener is a polyurethane thickener, the leveling agent is a fluorine-modified acrylate, and the anti-settling agent is fumed silica; the diisooctyl hyaluronic acid acid salt: sodium hexametaphosphate : Amide: Polyurethane thickener: Fluorine-modified acrylate: The mass ratio of fumed silica is 1:2:2:2:2:1; the coloring pigment and filler is iron oxide.

[0027] The preparation method of the metal ant...

Embodiment 2

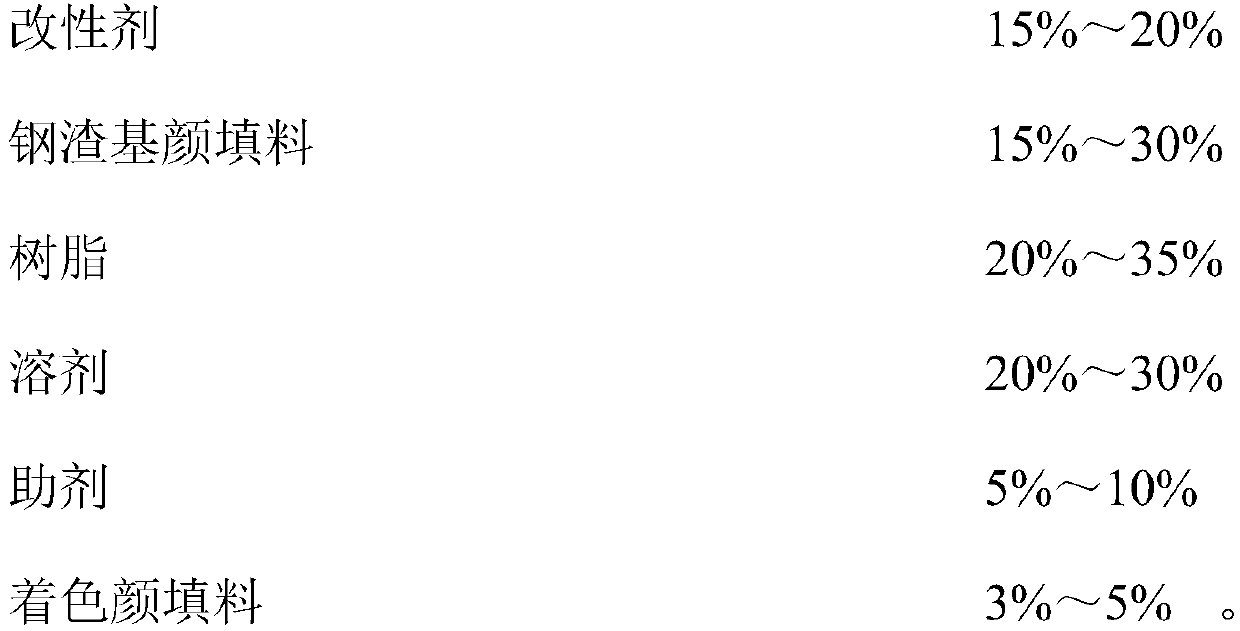

[0033] Modified steel slag-based pigments and fillers replace iron red metal antirust coatings, consisting of the following substances by weight percentage:

[0034]

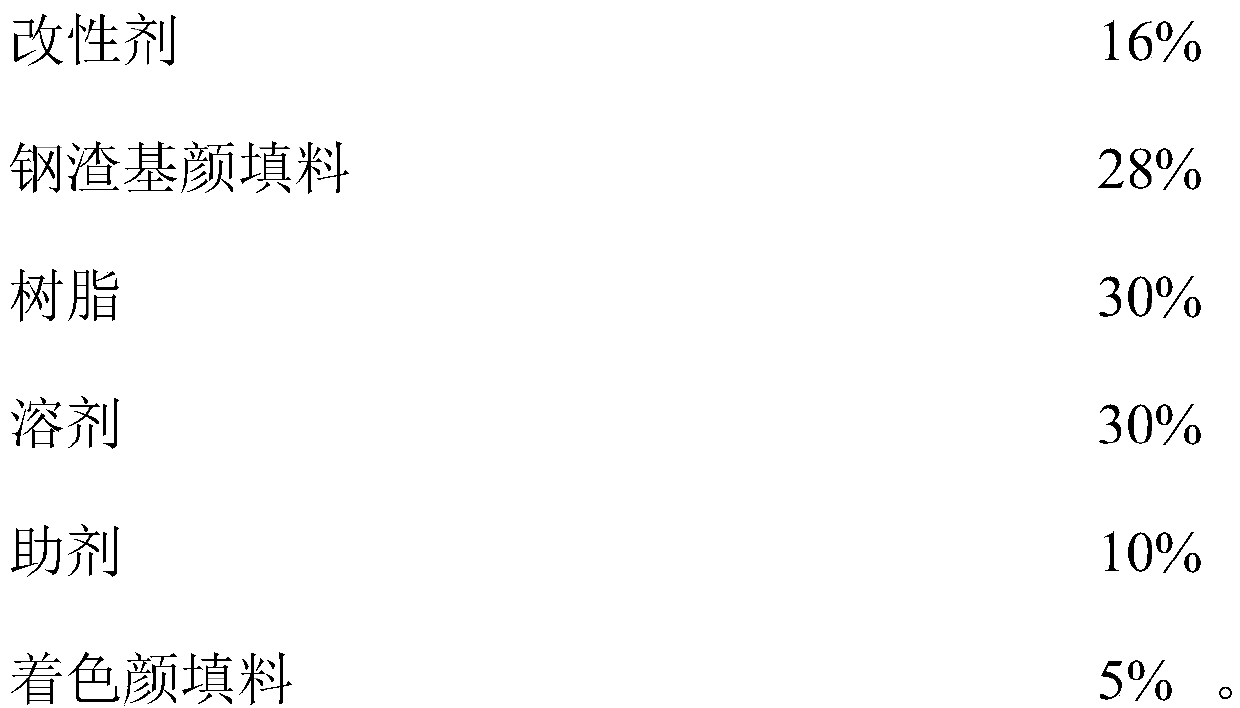

[0035]

[0036] The mixed solution of ferric chloride and sulfuric acid with a modifier pH value of 6.5 is selected; steel slag-based pigments and fillers are 400 mesh steel slag micropowder; the resin is a mixture of epoxy resin, alkyd resin and polyester resin; the solvent is ethyl ester and butyl mixture of esters; auxiliary agent is a mixture of wetting agent, dispersant, defoamer, thickener, leveling agent and anti-sedimentation agent; Sodium hexametaphosphate, the defoamer is an amide, the thickener is a polyurethane thickener, the leveling agent is a fluorine-modified acrylate, and the anti-sedimentation agent is fumed silica; Salt: Sodium Hexametaphosphate: Amide: Polyurethane Thickener: Fluorine-modified Acrylic Ester: The mass ratio of fumed silica is 1:2:2:2:2:1; the coloring pigment and filler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com