Potassium ion battery positive electrode active material, preparation method thereo fand application thereof

A battery cathode and active material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle performance and dead potassium battery rate performance, and achieve long cycle life, excellent rate performance, and extended cycle life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

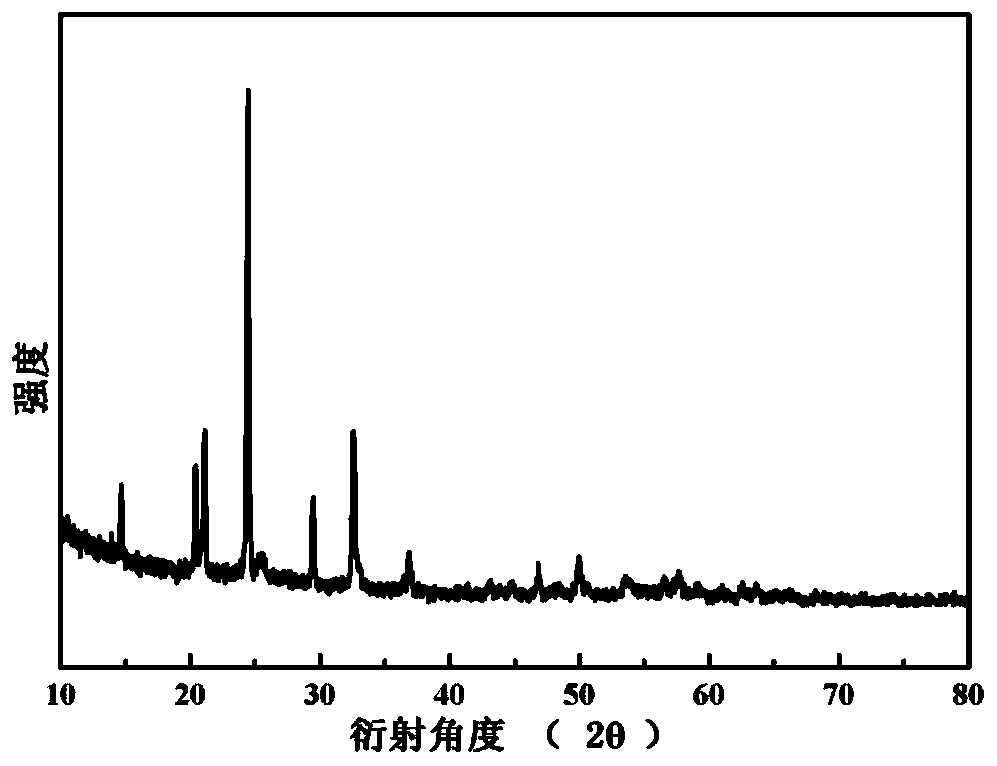

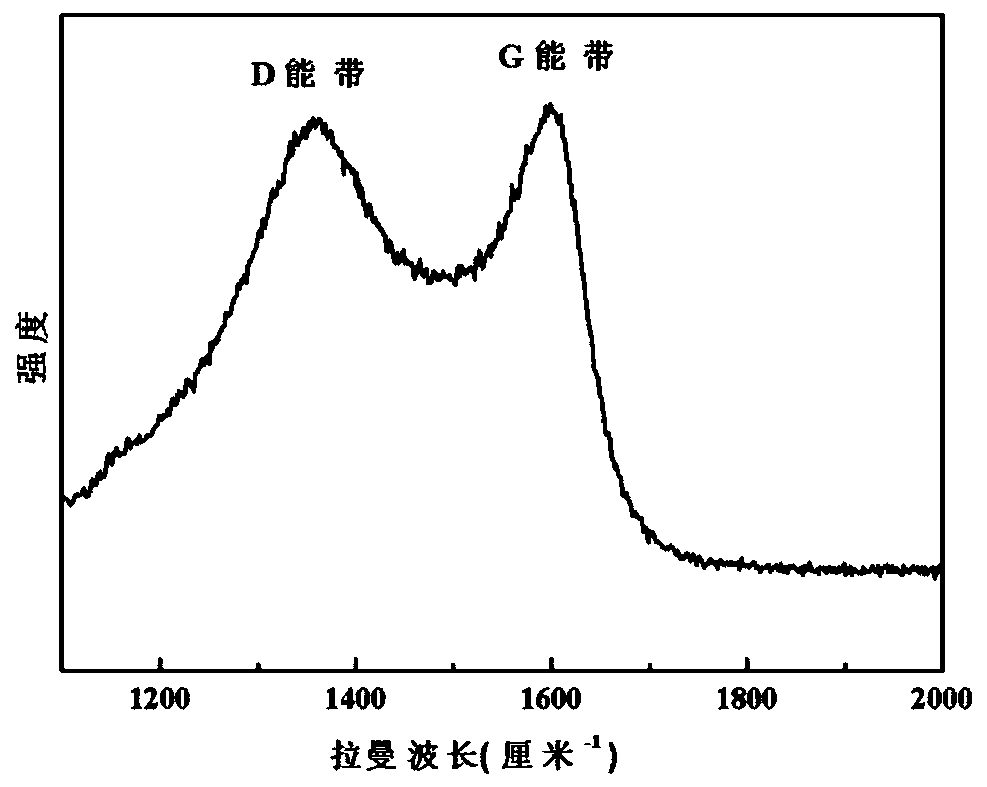

[0039] A positive electrode active material for potassium-ion batteries-carbon-coated zirconium-doped NaTi 2 (PO 4 ) 3 A preparation method comprising the steps of:

[0040] (1) Stir and disperse 1.8g of sodium dihydrogen phosphate, 2.397g of titanium dioxide, 5.176g of ammonium dihydrogen phosphate, and 0.9g of glucose in 20mL of distilled water, add 0.2g of zirconia and 3mL of ethanol, place them in an agate ball mill jar, add oxidation Zirconium beads, the mass ratio of balls is 1:1, ball milling at a speed of 500rpm for 5h to obtain a slurry, which is spray-dried at a temperature of 160°C and a drying flow rate of 20L / min to obtain a precursor;

[0041] (2) Place the precursor in a tubular heating furnace connected to a vacuum pump for vacuum annealing. During the treatment process, the vacuum is continuously pumped, and the temperature is raised to 300°C in the first program at a rate of 5°C / min under a vacuum atmosphere. , keep the temperature for 5 hours, then carry ...

Embodiment 2

[0047] A positive electrode active material for potassium-ion batteries-carbon-coated zirconium-doped NaTi 2 (PO 4 ) 3 A preparation method comprising the steps of:

[0048] (1) Stir and dissolve 1.8g of sodium dihydrogen phosphate, 1.9g of titanium dioxide, 3.45g of ammonium dihydrogen phosphate, and 0.27g of glucose in 30mL of distilled water, add 0.18g of zirconia and 4mL of ethanol, put them in an agate ball mill jar, add oxidation Zirconium beads, the mass ratio of balls is 1:1, ball milling at a speed of 400rpm for 7h to obtain a slurry, which is spray-dried at a temperature of 170°C and a drying flow rate of 10L / min to obtain a precursor;

[0049] (2) Place the precursor in a tube-type heating furnace connected to a vacuum pump for vacuum annealing. During the treatment process, the vacuum is continuously pumped, and the temperature is raised to 350°C in the first program at a rate of 3°C / min under a vacuum atmosphere. , keep the temperature for 3h, and then carry ou...

Embodiment 3

[0052] A positive electrode active material for potassium-ion batteries-carbon-coated zirconium-doped NaTi 2 (PO 4 ) 3 A preparation method comprising the steps of:

[0053] (1) Stir and dissolve 1.8g of sodium citrate, 3.6g of tetraethyl titanate, 6.9g of phosphoric acid, and 5.4g of glucose in 40mL of distilled water, add 0.27g of zirconia and 8mL of ethanol, put them in an agate ball mill jar, add oxidation Zirconium beads, the mass ratio of balls is 1:1, ball milling at a speed of 600rpm for 4h to obtain a slurry, which is spray-dried at a temperature of 150°C and a drying flow rate of 25L / min to obtain a precursor;

[0054] (2) Place the precursor in a tube-type heating furnace connected to a vacuum pump for vacuum annealing. During the treatment process, the vacuum is continuously pumped, and the temperature is raised to 700°C in the second program at a rate of 2°C / min under a vacuum atmosphere. , constant temperature for 2h, and naturally cooled to room temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com