Composite plywood and manufacturing method thereof

A manufacturing method and a technology for plywood, which are applied in the field of plywood manufacturing, can solve the problems of dimensional stability, poor crack resistance, poor heat and cold cycle resistance, formaldehyde pollution, and high production costs, achieve good cold and heat cycle resistance, and save production costs. , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

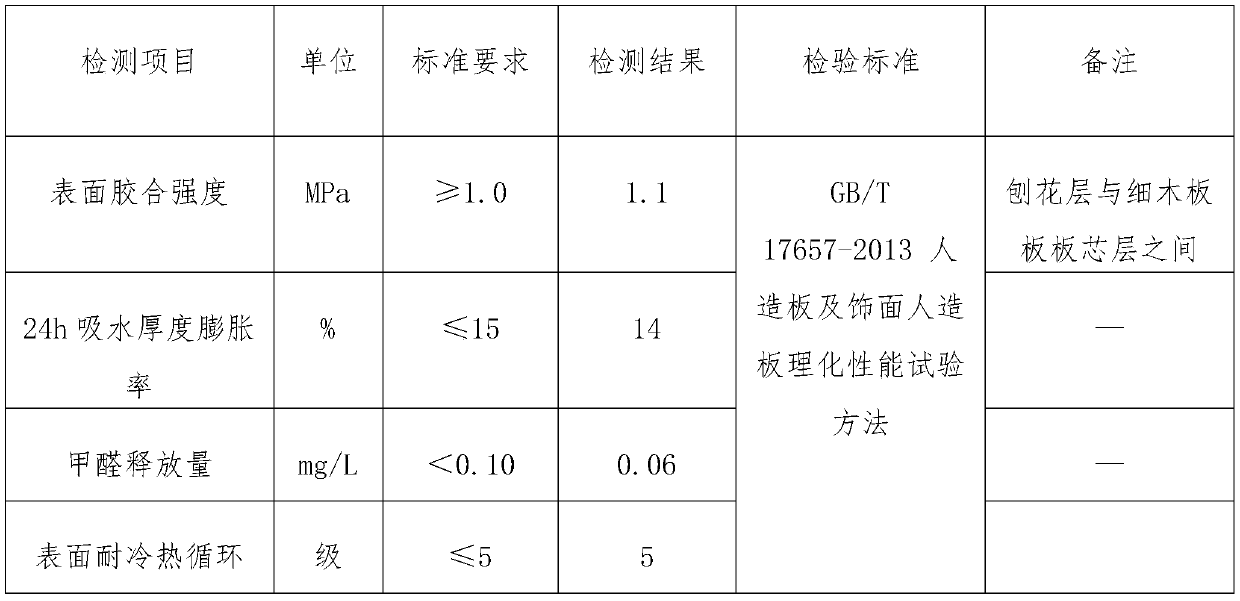

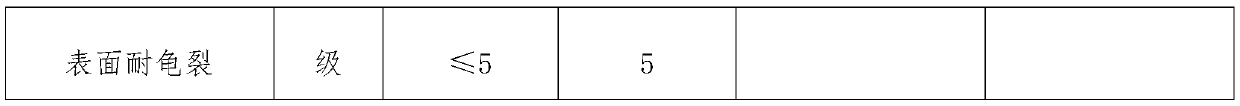

Embodiment 1

[0023] A method for manufacturing composite plywood, comprising the steps of:

[0024] Step 1: Stir the wood shavings evenly with the adhesive, which is a mixture of polyurethane adhesive, formaldehyde-free biomass adhesive, urea-formaldehyde, phenolic formaldehyde, melamine formaldehyde, waterproofing agent, anti-fungal agent and tackifier; sizing of the adhesive The amount is 7% to 35% of the weight of wood shavings, the water repellant is 0.05% to 3.4% of the weight of wood shavings, the antifungal agent is 0.01% to 4.5% of the weight of wood shavings, and the moisture content of the wood shavings is dried to 5% after being stirred with the adhesive ~12%; the size of the sieve for wood shavings is 0.11*0.11~1.53*1.53mm, and the wood shavings can be of any species except paulownia, such as poplar, eucalyptus, miscellaneous wood, etc.

[0025] Step 2: Pave the above-mentioned stirred wood shavings on the two board surfaces of the blockboard, and make wood shaving composite pl...

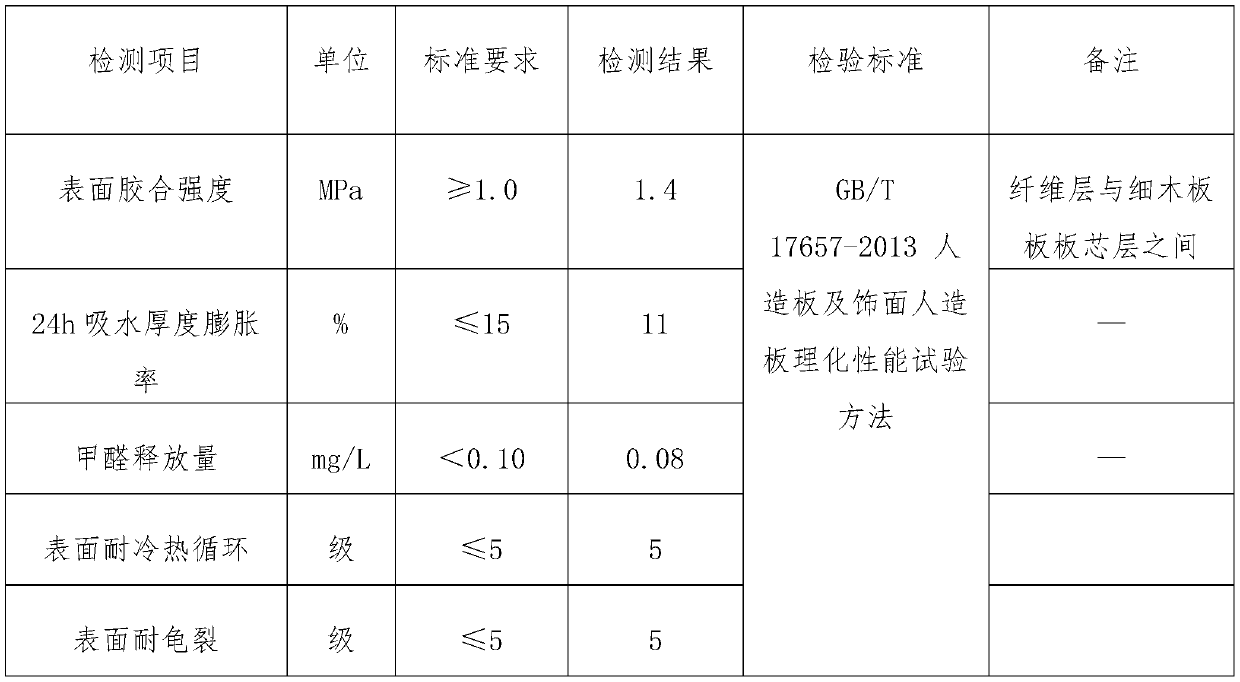

Embodiment 2

[0028] A method for manufacturing composite plywood, comprising the steps of:

[0029] Step 1. Stir the wood fiber and adhesive evenly. The adhesive is a mixture of polyurethane adhesive, formaldehyde-free biomass adhesive, urea-formaldehyde, phenolic formaldehyde, melamine formaldehyde, waterproofing agent, anti-fungal agent and tackifier; sizing of the adhesive The amount is 7% to 35% of the weight of the wood fiber, the water repellant is 0.05% to 3.4% of the weight of the wood fiber, the antifungal agent is 0.01% to 4.5% of the weight of the wood fiber, and the moisture content of the wood fiber is dried to 3% after being stirred with the adhesive. % ~ 15%; the thickness of wood fiber is 0.2 ~ 0.6mm, the wood fiber species can be except paulownia, such as poplar, eucalyptus, miscellaneous wood, etc.

[0030] Step 2: Pave the above-mentioned stirred wood fiber on the two board surfaces of the plywood, and heat press at high temperature to make a wood fiber composite plywood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com