Waste cooking oil-based polyester derivative grease and preparation method thereof

A technology of ester derivatives and catering waste oil, which is applied in the field of lubricating oil, can solve the problems of poor thermal stability, low product viscosity, difficult lubricating oil, etc., and achieve the effect of high stability, simple components, and high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

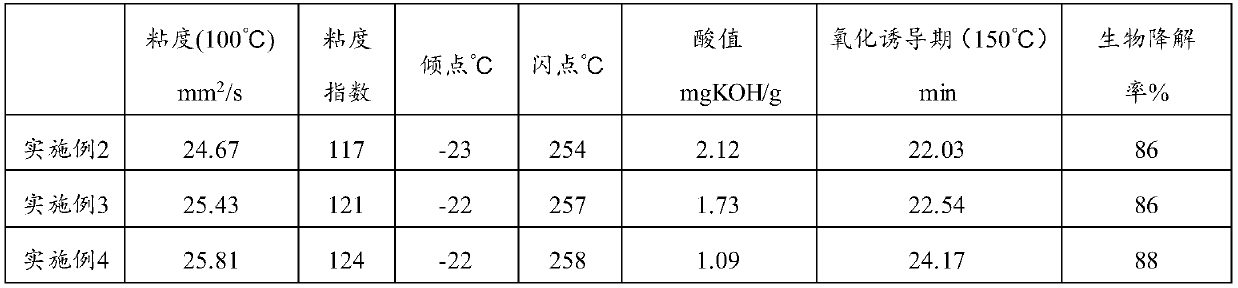

Examples

preparation example Construction

[0056] The invention provides a method for preparing polyester derivative oil based on waste cooking oil, comprising the following steps:

[0057] a) mixing waste catering oil with NaOH solution for hydrolysis reaction, and removing the glycerol generated by the reaction, and then acidifying the remaining product after removing glycerin with acid to obtain fatty acid;

[0058] b) under the action of a solid acid catalyst, the fatty acid is esterified with neopentyl glycol to form fatty acid neopentyl glycol ester;

[0059] c) under the action of a catalyst, the fatty acid neopentyl glycol ester is mixed with formic acid and hydrogen peroxide to carry out an epoxidation reaction to form epoxy fatty acid neopentyl glycol ester;

[0060] d) Under the action of a basic catalyst, the epoxy fatty acid neopentyl glycol ester is subjected to a ring-opening reaction with acetic acid to obtain a polyester derivative oil.

[0061] In the preparation method provided by the present invent...

Embodiment 1

[0108] Take waste cooking oil and heat it at 80°C for 1 hour, filter through filter cloth to remove solid impurities, wash 3 times with distilled water, transfer to a separatory funnel to remove water-soluble impurities, take the upper oil, add activated carbon for adsorption (activated carbon and oil The mass ratio is 1:10), the oil is decolorized, filtered by suction, and refined catering waste oil is obtained.

Embodiment 2

[0110] S1, add 75g NaOH solution (13.83wt%) to 100g refined catering waste oil, hydrolyze 4h at 90 ℃, utilize saturated NaCl solution to wash and remove glycerin; Add 39g NaOH solution (6.92wt%) in the remaining mixture again, Continue to hydrolyze at ℃ for 2h, wash with saturated NaCl solution to remove glycerol, and obtain fatty acid sodium. Add 35g of concentrated hydrochloric acid (36.7wt%) to it, acidify and react at 60°C for 3h, collect the product, and distill off the residual moisture at 60°C and 0.095MPa to obtain fatty acid.

[0111] S2. Take 75g of fatty acid, 17.86g of neopentyl glycol, and 0.375g of solid acid catalyst HND-26, mix and react at 120°C for 6 hours; collect the catalyst by filtration, wash the filtrate with saturated NaCl solution 3 times to remove residual neopentyl Diol; then distill off residual moisture under reduced pressure at 60°C and 0.095MPa to obtain fatty acid neopentyl glycol.

[0112] S3. Take 70g of fatty acid neopentyl glycol, 7g of fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com