Copper sulfide quantum dot/cuprous thiocyanate heterojunction photoelectric film and preparation method thereof

A cuprous thiocyanate, photoelectric thin film technology, applied in photosensitive devices, circuits, electrical components, etc., can solve the problem of high photo-generated carrier recombination rate, achieve low cost, improve photoelectrochemical performance, and obvious modification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

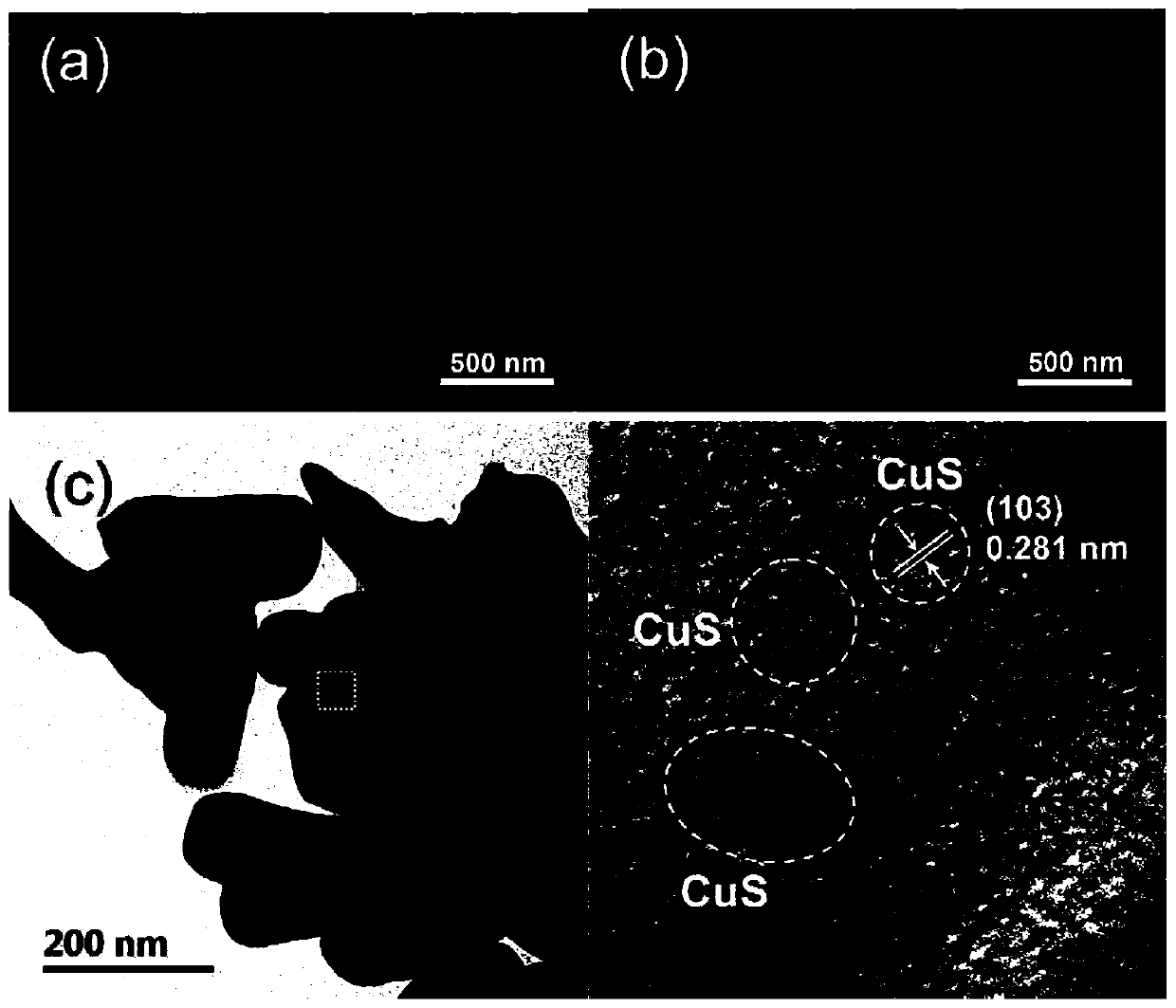

[0018] (1) Dissolve 4 mmol of anhydrous copper acetate in 40 mL of an aqueous solution containing 0.01 mmol of surfactant polyvinylpyrrolidone (PVP, molecular weight 58000 g / mol), at 70 o After stirring for 30 minutes under C, a 0.1 M copper acetate solution was formed; then at a constant temperature of 70 o Add 40 mL of 0.1 M thiourea solution dropwise to the copper acetate solution under stirring conditions, and continue to keep the temperature for 70 o After stirring at C for 60 minutes, stop heating; after the solution is naturally cooled to room temperature, the precipitate is collected by high-speed centrifugation. o C and dried overnight, CuS quantum dots can be prepared.

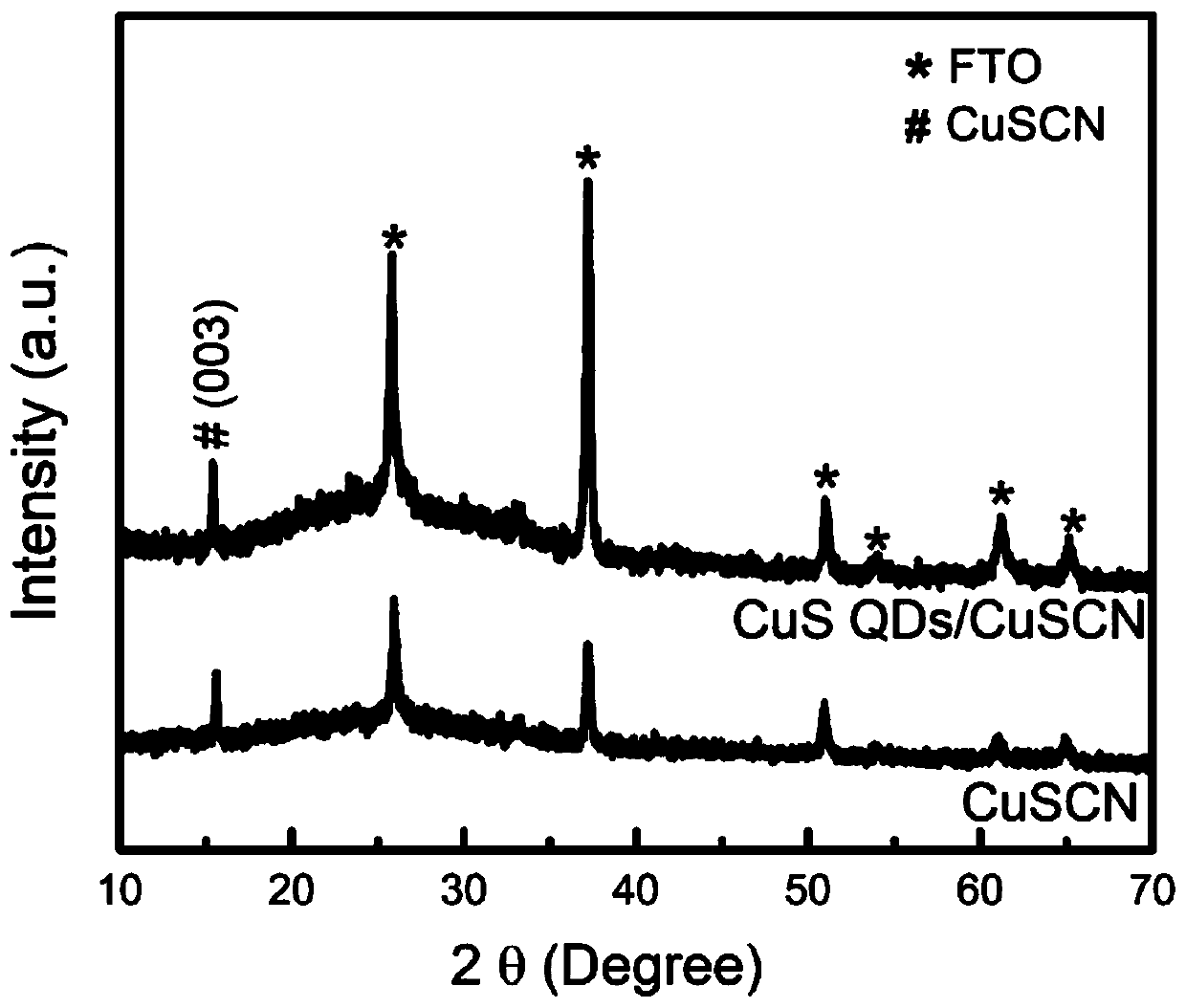

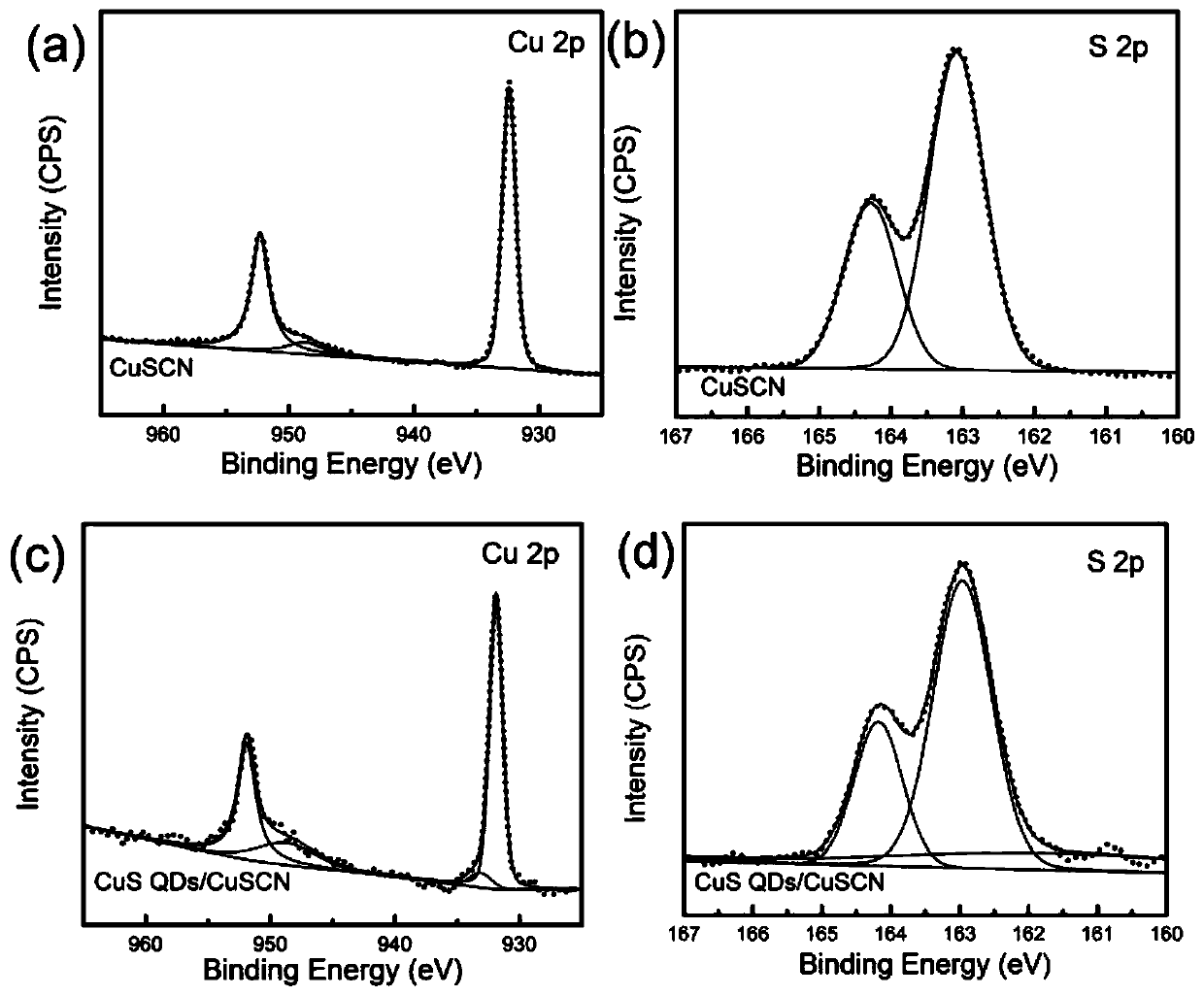

[0019] (2) Disperse 3.2 mg CuS quantum dots obtained above into 200 mL deionized water to prepare CuS quantum dot dispersion with a concentration of 16 mg / L; then 2.4 mmol copper sulfate pentahydrate (CuSO 4 ∙5H 2 O), 2.4 mmol ethylenediaminetetraacetic acid (EDTA) and 0.6 mmol potassium thiocyana...

Embodiment 2

[0021] (1) The preparation process of CuS quantum dots is the same as in Example 1.

[0022] (2) On the premise of obtaining the above-mentioned CuS quantum dots, 2 mg of CuS quantum dots obtained above were dispersed into 200 mL of deionized water to prepare a dispersion of CuS quantum dots with a concentration of 10 mg / L; then 2.4 mmol Copper Sulfate (CuSO 4 ∙5H 2 O), 2.4 mmol ethylenediaminetetraacetic acid (EDTA) and 0.6 mmol potassium thiocyanate (KSCN) were sequentially dissolved into the CuS quantum dot dispersion, and stirred to prepare CuSO 4 Precursor solution with a concentration of 12 mM and containing CuS quantum dots; the prepared precursor solution was transferred to the electrochemistry of a three-electrode system equipped with a platinum wire counter electrode, a calomel reference electrode, and a cleaned FTO or ITO conductive glass. In the reaction tank, at a deposition potential of -0.4 V and a deposition charge of 80 mC / cm 2 Electrochemical deposition wa...

Embodiment 3

[0024] (1) The preparation process of CuS quantum dots is the same as in Example 1.

[0025] (2) On the premise of obtaining the above-mentioned CuS quantum dots, disperse the 6 mg CuS quantum dots obtained above into 200 mL deionized water to prepare a dispersion of CuS quantum dots with a concentration of 30 mg / L; then 2.4 mmol five Copper Sulfate (CuSO 4 ∙5H 2 O), 2.4 mmol ethylenediaminetetraacetic acid (EDTA) and 0.6 mmol potassium thiocyanate (KSCN) were sequentially dissolved into the CuS quantum dot dispersion, and stirred to prepare CuSO 4 Precursor solution with a concentration of 12 mM and containing CuS quantum dots; the prepared precursor solution was transferred to the electrochemistry of a three-electrode system equipped with a platinum wire counter electrode, a calomel reference electrode, and a cleaned FTO or ITO conductive glass. In the reaction tank, at a deposition potential of -0.3 V and a deposition charge of 60 mC / cm 2 Electrochemical deposition was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com