Internal pressure type composite hollow fiber nanofiltration membrane filament and preparation method thereof

An internal pressure, nanofiltration membrane technology, applied in the field of hollow fiber membranes, can solve the problem of poor oxidation resistance/free chlorine resistance/pollution resistance of ultra-thin separation layer, poor oxidation resistance/free chlorine resistance and antifouling performance, composite nanofiltration Membrane pretreatment measures limit and other problems, to achieve easy large-scale production, good divalent salt interception effect, flux and high divalent salt interception effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of hollow fiber ultrafiltration base membrane, the membrane system includes feed liquid and core liquid.

[0048] According to the weight ratio, take 24 parts of polyethersulfone, 30 parts of non-solvent and 46 parts of solvent in the reactor at a temperature of 50 degrees Celsius and stir to dissolve. After 24 hours, vacuum defoaming for 12 hours to obtain a homogeneous feed solution;

[0049] According to the weight ratio, 10 parts of solvent and 90 parts of water were successively taken in the reactor and stirred and dissolved at room temperature for 4 hours to obtain the core liquid;

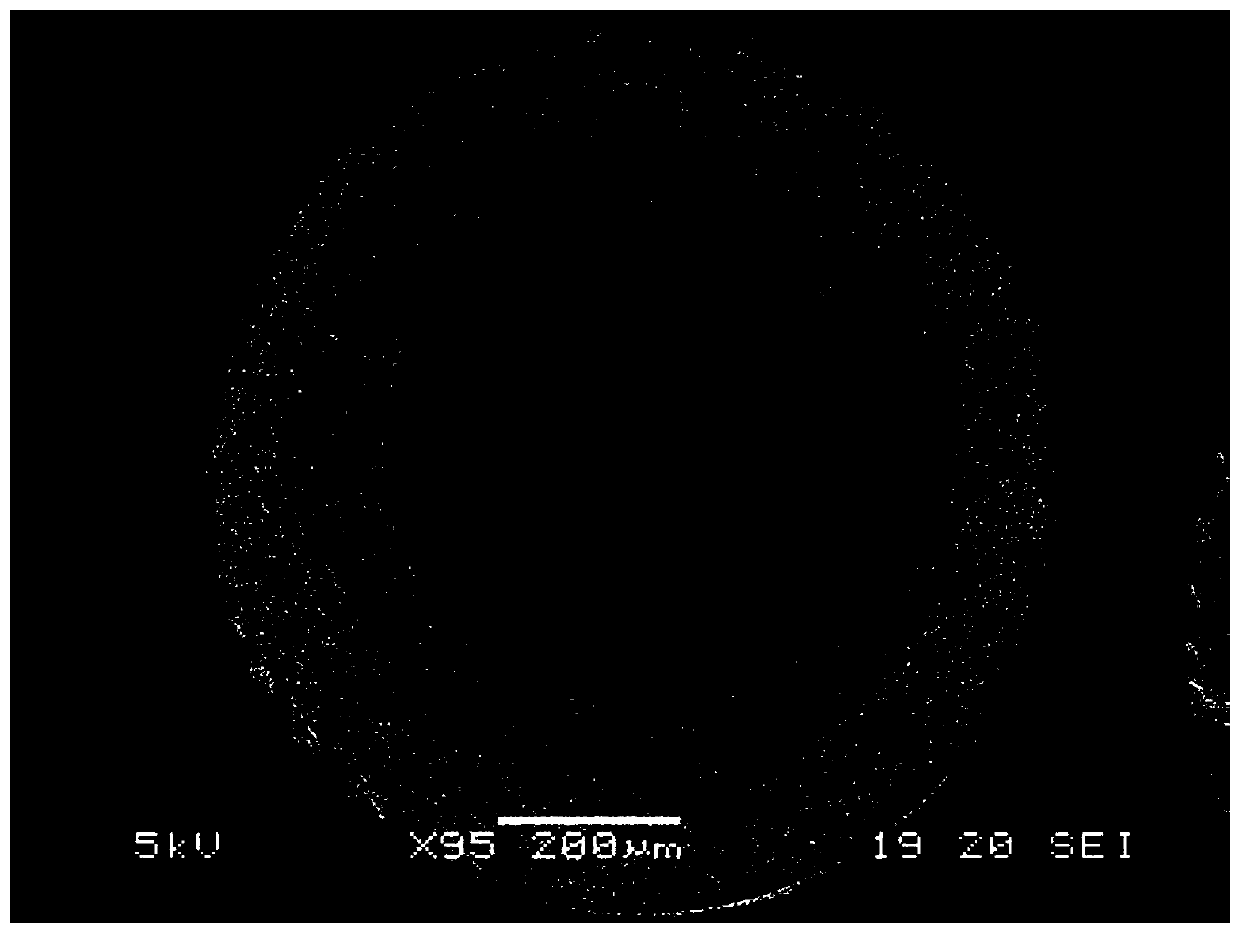

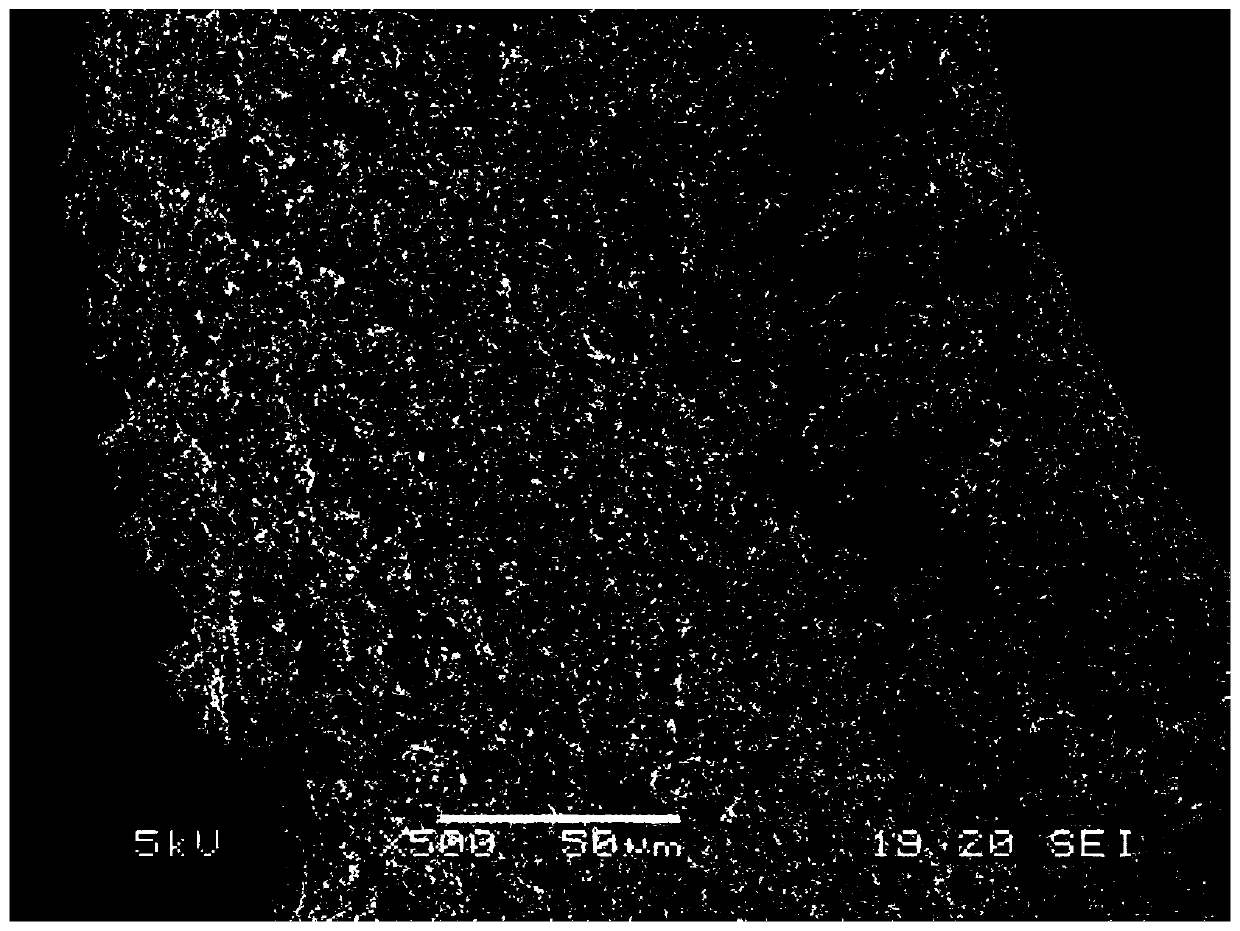

[0050] The feed liquid and the core liquid are respectively injected into a spinneret through the casting liquid channel and the core liquid channel through the gear pump, and the hollow tubular liquid film is extruded through the casting liquid port and the core liquid port of the spinneret. Then, the liquid membrane passes through two coagulation baths successively af...

preparation Embodiment 2

[0055] 1. The preparation of the hollow fiber ultrafiltration base membrane is the same as the preparation example one;

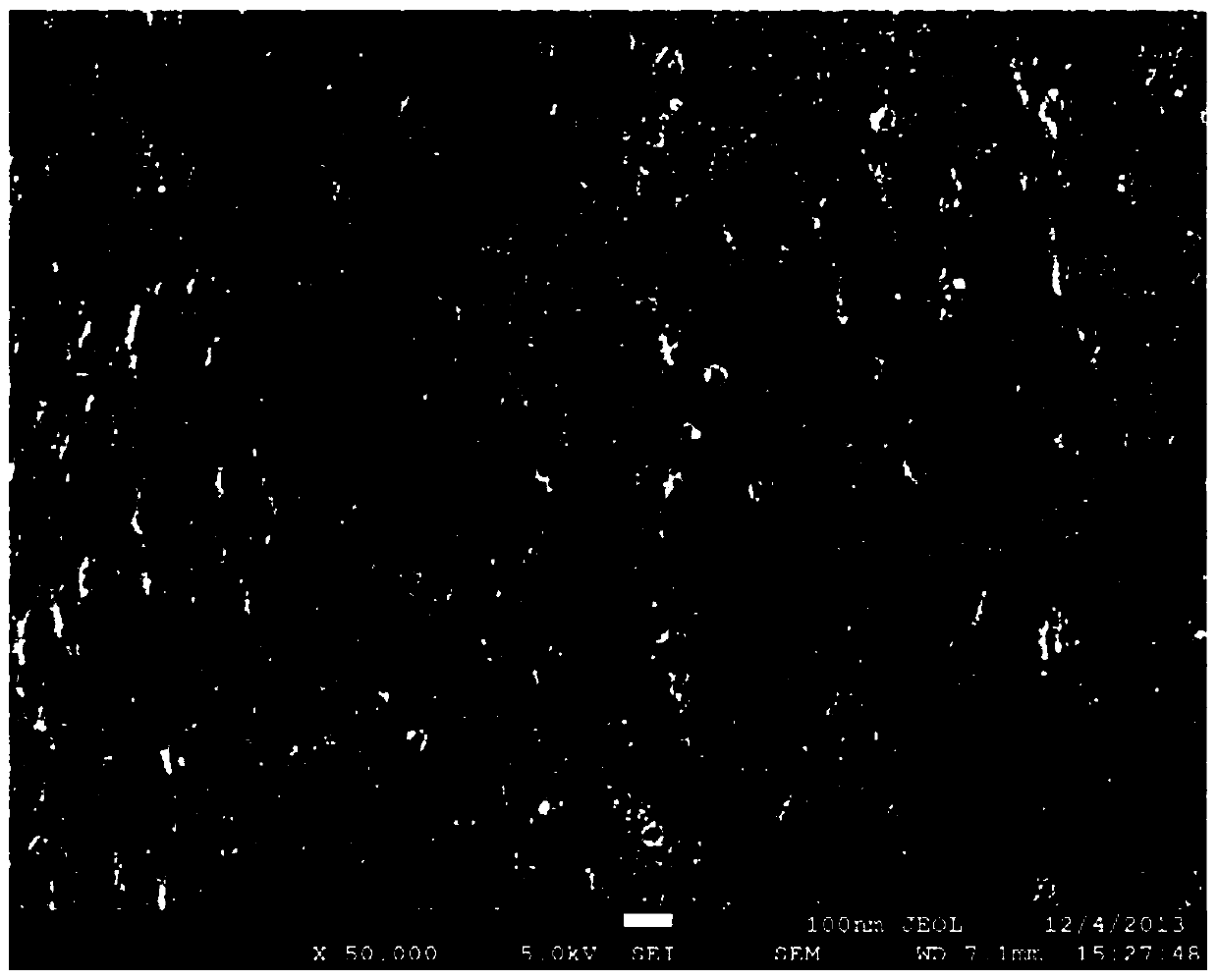

[0056] 2. Preparation of the composite nanofiltration membrane: a layer of cross-linked polyamine dense selective layer is formed by cross-linking on the skin layer of the polyethersulfone base membrane, and the cross-linking system includes a first cross-linking solution and a second cross-linking solution.

[0057] The formula of the first cross-linking solution is polyethyleneimine 2%, sodium dodecylbenzene sulfonate 0.05% and water 97.95%; the formula of the second cross-linking solution is glutaraldehyde 3%, water 97%. The coupling agent and deionized water are placed in a stirring tank, stirred and mixed for 2 hours at a speed of 60-80 r / min, and left to stand for 1 hour to obtain a cross-linking liquid. Soak the polyethersulfone base membrane in the first crosslinking solution, control the temperature at 35 degrees Celsius, take it out after soaking ...

preparation Embodiment 3

[0059] 1. The preparation of the hollow fiber ultrafiltration base membrane is the same as the preparation example one;

[0060] 2. Preparation of composite nanofiltration membrane:

[0061] A dense selective layer of cross-linked polyamine is formed by cross-linking on the skin layer of the polyethersulfone base membrane, and the cross-linking system includes a first cross-linking solution and a second cross-linking solution.

[0062] The formula of the first cross-linking solution is polypropylene amine 8%, sodium dodecylbenzene sulfonate 0.04% and water 91.96%; The formula of the second cross-linking solution is glutaraldehyde 6%, water 94%, will cross-link Place the agent and deionized water in a stirring tank, stir and mix for 2 hours at a rotating speed of 60-80 r / min, and obtain a cross-linking liquid after standing for 1 hour. Soak the polyethersulfone base membrane in the first crosslinking solution, control the temperature at 35 degrees Celsius, take it out after so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com