A kind of photoelectric catalytic anode material and treatment method for removing phthalates

A phthalic acid and photoelectric catalysis technology, which is applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of single identification types, poor photocatalytic activity, high environmental toxicity, etc., and achieve High removal efficiency, good pertinence and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of photoelectric catalytic anode material that removes phthalates, its preparation method comprises the following steps:

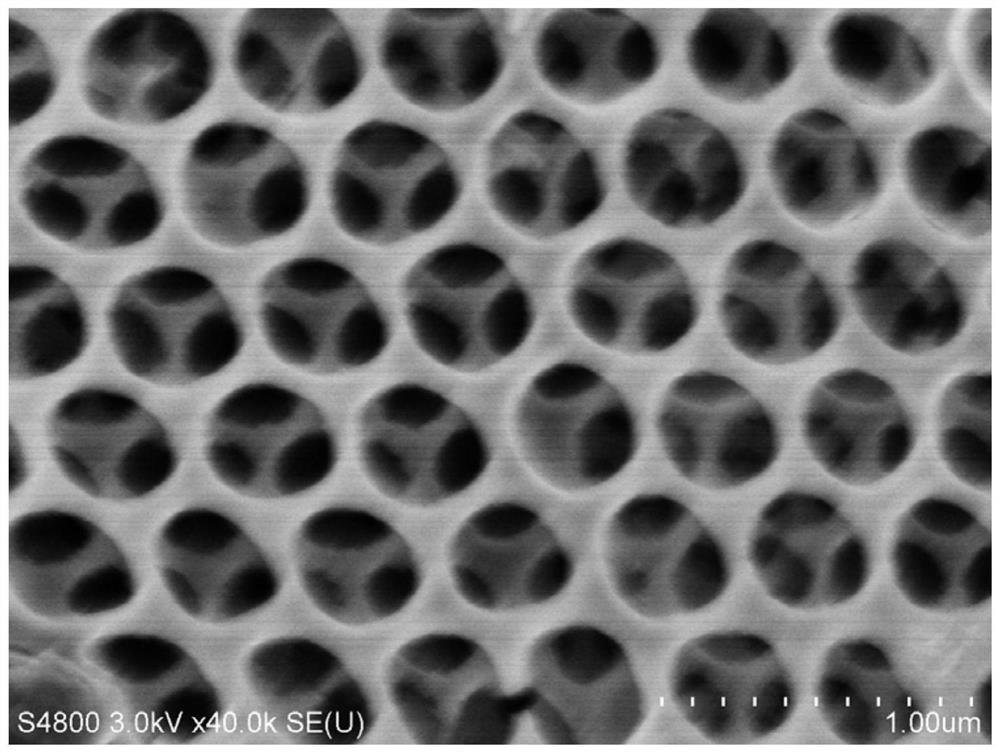

[0025] 1) At room temperature, template molecules (phthalic anhydride or dibutyl phthalate) are added to a certain volume of polystyrene microspheres or silica microspheres in a dispersion containing 274mg / L, The mass ratio of the template molecule to the microsphere was 20. The polystyrene microspheres or silica microspheres used have a diameter of 350 nm. After that, 50 mg / L of 2-(N-morpholino)ethanesulfonic acid was added, and stirred at 60° C. for 300 min in the absence of oxygen.

[0026] 2) Place the conductive surfaces of two pieces of conductive glass (fluorine-doped tin dioxide or fluorine-doped indium tin oxide) facing each other, vertically put them into the solution in step 1), and place them on an anti-seismic table while avoiding vibration. After 72 hours, the solution was completely evaporated, and the template-preassembled e...

Embodiment 2

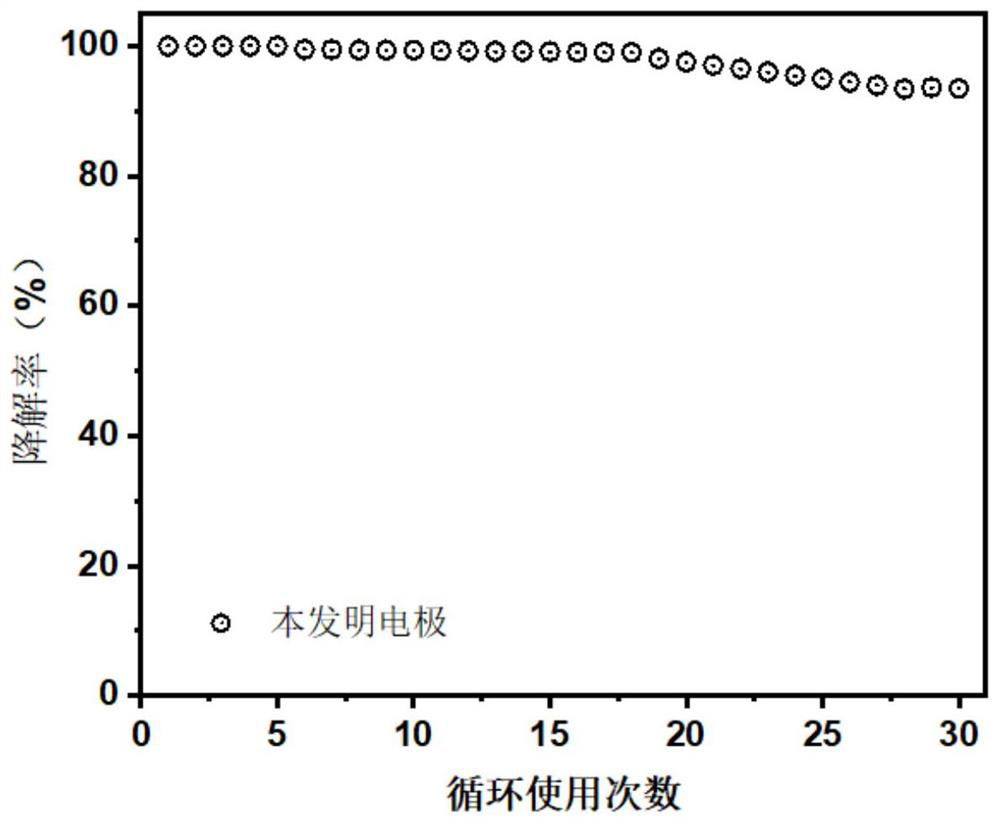

[0029] In a reactor made of quartz, the photoelectrocatalytic anode material imprinted with a pseudo-template prepared in Example 1 is used as the photoanode, the platinum sheet is used as the cathode, and the saturated calomel electrode (SCE) is used as the reference electrode, and the electrolyte solution is: containing 0.3mol L -1 0.1mol L of phthalates -1 Sodium sulfate electrolyte solution. A 300W short-arc Xe lamp was equipped with a UV filter as the light source, and a bias voltage of 0.6V (vs. SCE) was applied. Finally, qualitative and quantitative determinations were carried out by high-resolution liquid chromatography-mass spectrometry. The photocatalytic anode material has a photocatalytic degradation kinetics of phthalates up to 0.0132min -1 , which is 6.98 times that of ordinary titanium dioxide photoanodes.

Embodiment 3

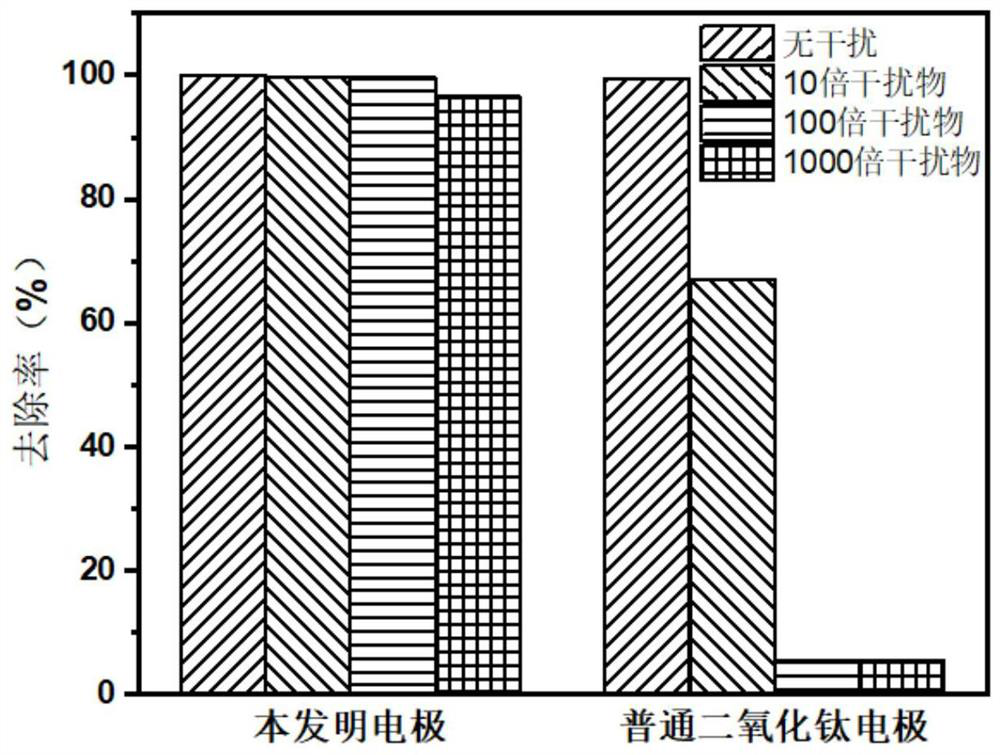

[0031] In a reactor made of quartz, the photoelectrocatalytic anode material imprinted with a pseudo-template prepared in Example 1 is used as the photoanode, the platinum sheet is used as the cathode, and the saturated calomel electrode (SCE) is used as the reference electrode, and the electrolyte solution is: containing 0.1mol L -1 0.1mol L of phthalates -1Sodium sulfate electrolyte solution. A 300W short-arc Xe lamp was equipped with a UV filter as the light source, and a bias voltage of 0.6V (vs. SCE) was applied. Finally, qualitative and quantitative determinations were carried out by high-resolution liquid chromatography-mass spectrometry. The photoelectrocatalytic anode material has high selectivity, such as figure 2 As shown, under the interference of 1000 times the concentration of natural organic matter, its removal efficiency of phthalates is not affected; while ordinary titanium dioxide electrode is under the interference of 100 times of natural organic matter,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com