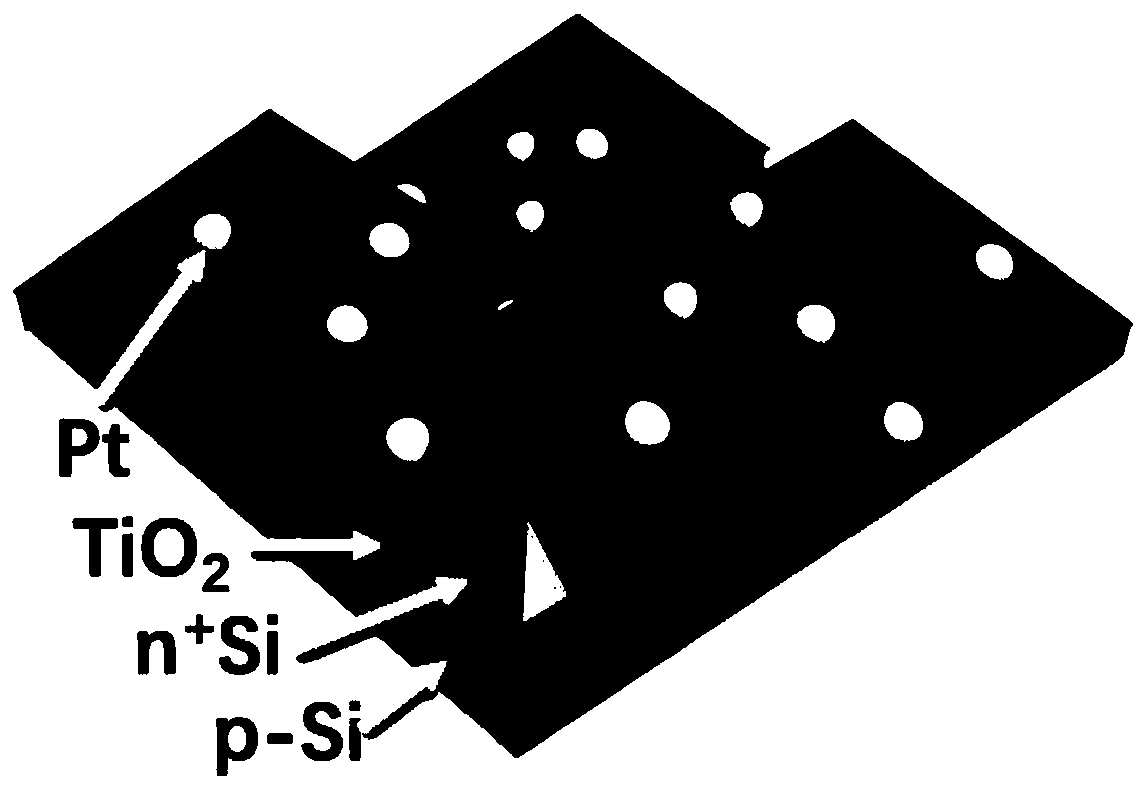

Pyramid silicon-based photocathode with uniform pn homojunction layer and preparation method thereof

A homojunction and pyramid technology, applied in chemical instruments and methods, electrodes, coatings, etc., can solve the problems of complex operation, high toxicity, uneven pn homojunction layer, etc., to achieve safe preparation process and enhance stability. , Improve the efficiency of photoelectric water splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

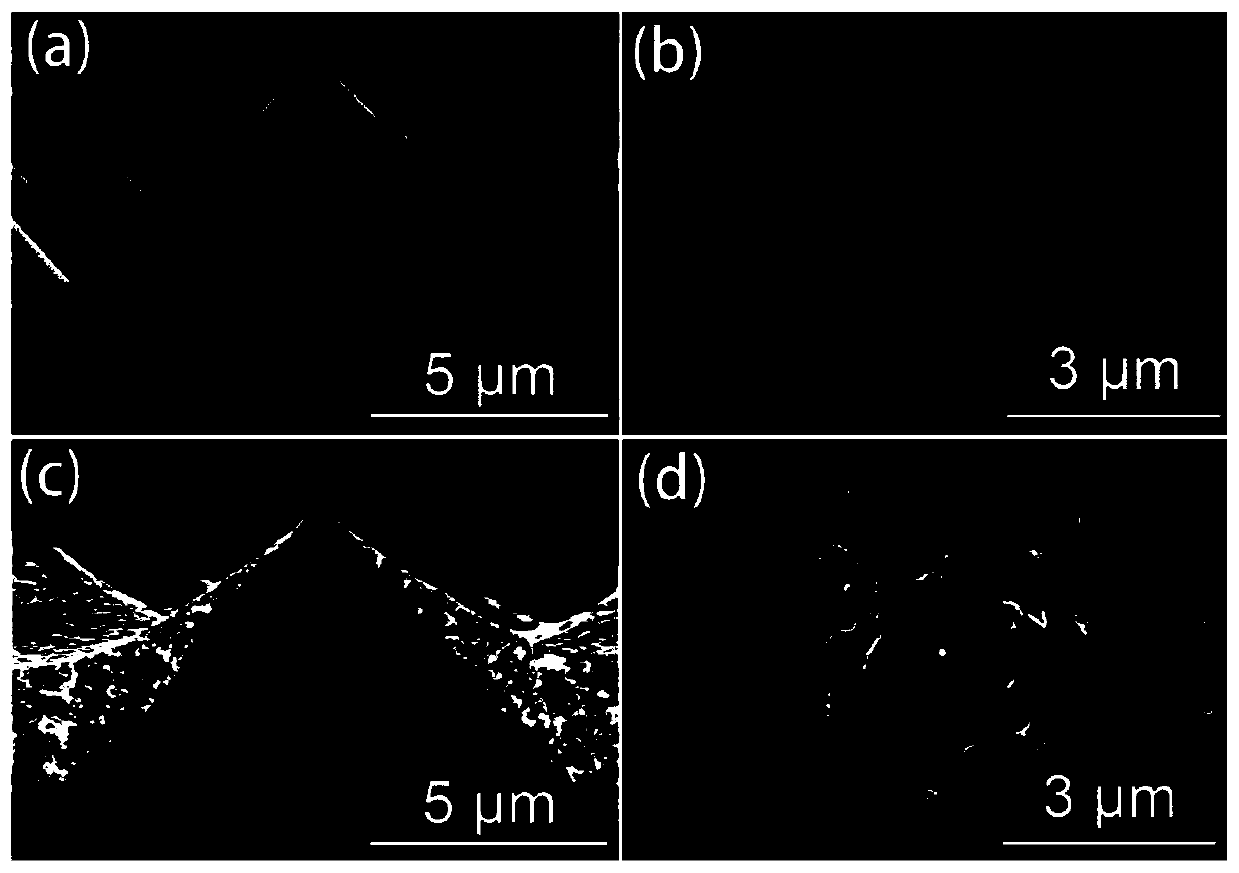

[0047] (1) Silicon wafer etching: Cut the p-Si finished product into several small squares of 3cm×3cm, heat the etching solution (KOH solution with a mass fraction of 6%, isopropanol with a volume fraction of 3%) in a water bath to 80°C, and The cut silicon wafers were put neatly into the Teflon flower basket and then transferred to the prepared solution. Cover the beaker with plastic wrap and react in a water bath at 80°C for 25 minutes, then take out the silicon wafer with tweezers, rinse it with ultrapure water, and dry it with a nitrogen gun.

[0048] (2) Cleaning of the silicon wafer, adopting standard RCA cleaning technology to clean the pyramidal silicon substrate obtained in (1), is divided into three steps:

[0049] In the first step, follow V 浓硫酸 :V 过氧化氢 =3:1 Prepare the piranha solution, heat it in a water bath at 85°C, put the above-treated silicon chip into it after the temperature is constant, react for 10 minutes, then take it out, rinse it with ultrapure wate...

Embodiment 2

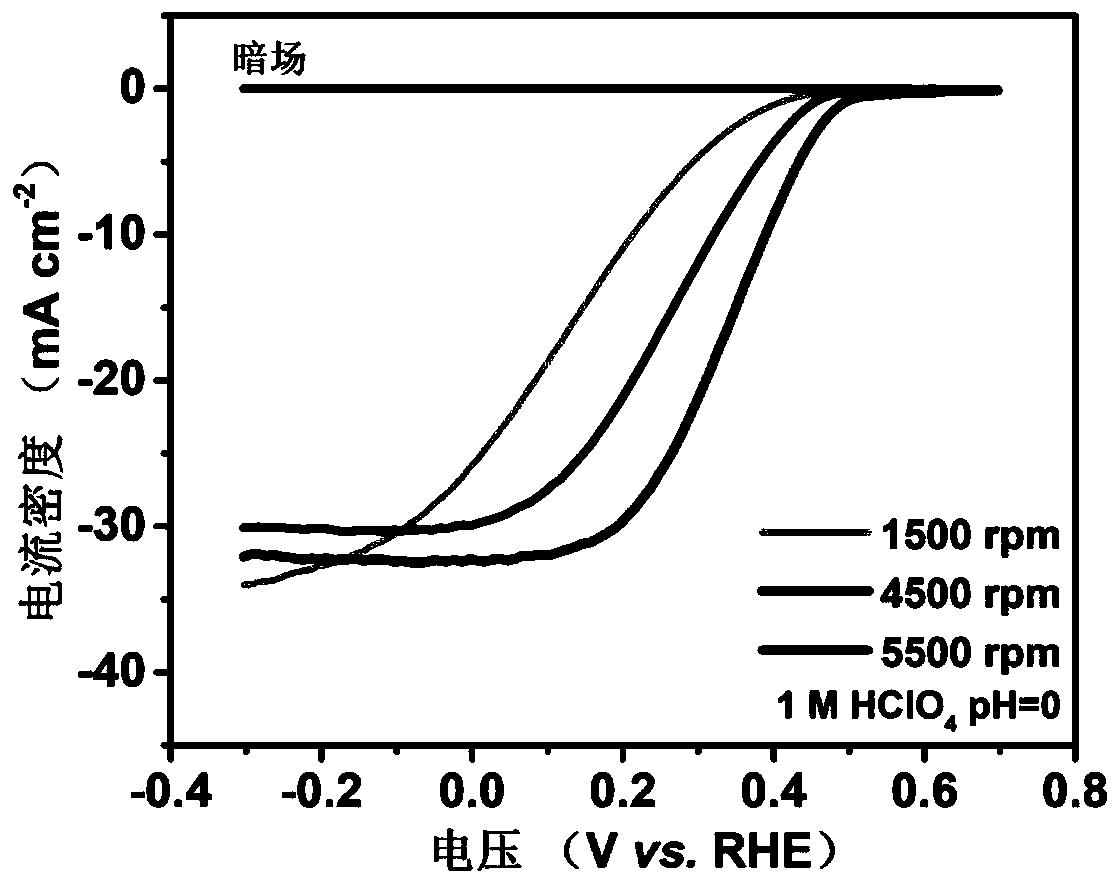

[0059] With embodiment (1) difference only lies in: (3) pn + Preparation of Si: In the second step, the rotational speed of the spin coater is set to 1500 rpm.

Embodiment 3

[0061] With embodiment (1) difference only lies in: (3) pn + Preparation of Si: In the second step, the rotational speed of the spin coater is set to 5500 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com