Heavy metal and soluble phosphorus contaminated soil remediation agent and treatment process thereof

A soil remediation agent and a treatment process technology, which are applied in the field of heavy metal and soluble phosphorus-contaminated soil remediation agents and their treatment processes, can solve problems such as impact and phosphorus exceeding the standard, and achieve the effects of improving life quality, soil environmental quality and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

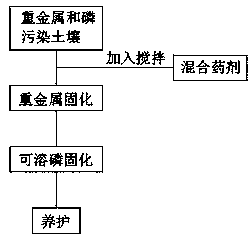

Method used

Image

Examples

Embodiment 1

[0025] Raw material: 500g of heavy metal and phosphorus polluted soil;

[0026] Agent: Mixed agent (30% potassium dihydrogen phosphate, 15% quicklime, 15% cement, 35% iron sulfate, 5% sodium lignosulfonate), polyaluminum chloride (PAC) (0.1%), polyacrylamide ( PAM) (0.1%);

[0027] Mixed agent / raw material ratio: 2.0:100;

[0028] temperature: room temperature;

[0029] Experimental steps: add the mixed agent and raw materials into the stirring equipment, stir and mix for 60 minutes, then add polyaluminum chloride (PAC), stir again for 60 minutes, and finally add polyacrylamide (PAM) and continue stirring for 30 minutes. Conservation for 7 days.

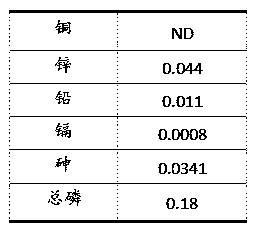

[0030] The experimental results, the analysis results of soil heavy metal content and total phosphorus content (unit: mg / L).

[0031]

Embodiment 2

[0033] Raw material: 500g of heavy metal and phosphorus polluted soil;

[0034] Agent: Mixed agent (45% potassium dihydrogen phosphate, 25% quicklime, 20% zeolite powder, 5% potassium chloride, 5% sodium dodecylbenzenesulfonate), cement 2g, polymerized iron sulfate (SPFS) 6g, Polyacrylamide (PAM) 5g;

[0035] Mixed agent / raw material ratio: 1:100;

[0036] temperature: room temperature;

[0037] Maintenance time: 7 days;

[0038] Experimental steps: add the mixed agent + cement and raw materials into the mixing equipment, stir and mix for 60 minutes, add polymeric ferric sulfate (SPFS), stir for 60 minutes, and finally add polyacrylamide (PAM), continue to stir for 30 minutes, and maintain for 7 days.

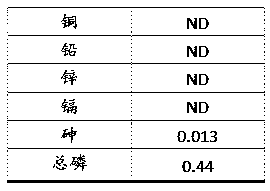

[0039] Experimental results, analysis results of soil heavy metals and total phosphorus content (unit: mg / L)

[0040]

Embodiment 3

[0042] Raw material: 500g of heavy metal and phosphorus polluted soil;

[0043] Agents: sodium dihydrogen phosphate, quicklime, cement, iron sulfate, sodium lignosulfonate;

[0044] temperature: room temperature;

[0045] Stirring time: 60min;

[0046] Maintenance time: 7 days;

[0047] The dosage of the drug is as follows:

[0048]

[0049] The content of heavy metals in soil flooding was analyzed under the conditions of different chemical dosage ratios, and the results are shown in the following table:

[0050] Analysis results of heavy metal content in soil water soaked in sodium dihydrogen phosphate solidification experiment (unit: mg / L)

[0051]

[0052] The experimental results show that the heavy metal content and total phosphorus content of soil flooding can simultaneously meet the Class IV standard in Table 1 of "Surface Water Environmental Quality Standard" (GB3838-2002).

[0053] The present invention adopts stabilizer and fixative combination technology ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com