High-water-resistance real stone paint for building exterior wall and preparation method thereof

A water-resistant technology for building exterior walls, applied in the field of coatings, can solve problems such as short life, reduced use of defoamers and thickeners, and easy whitening of paint films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

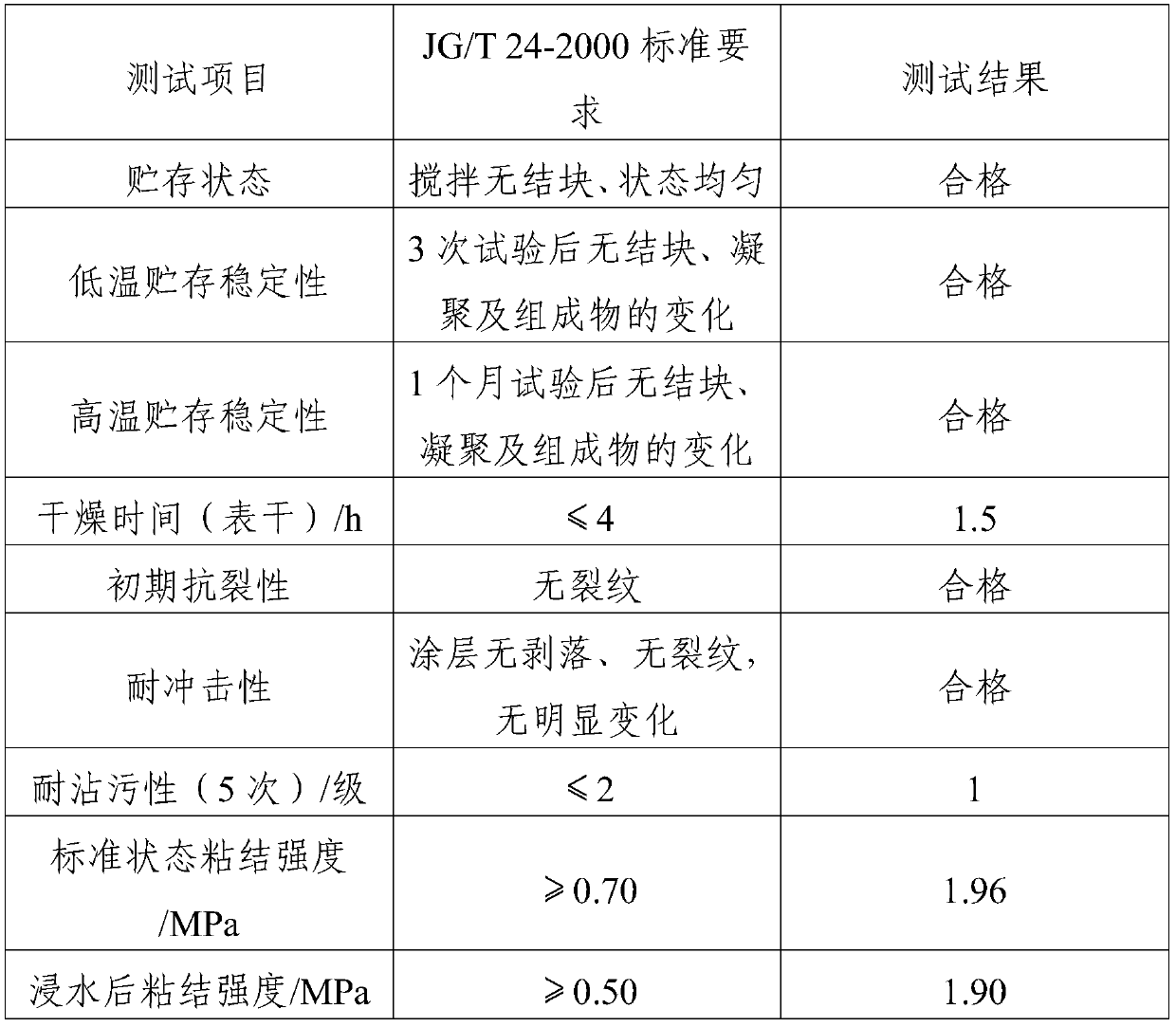

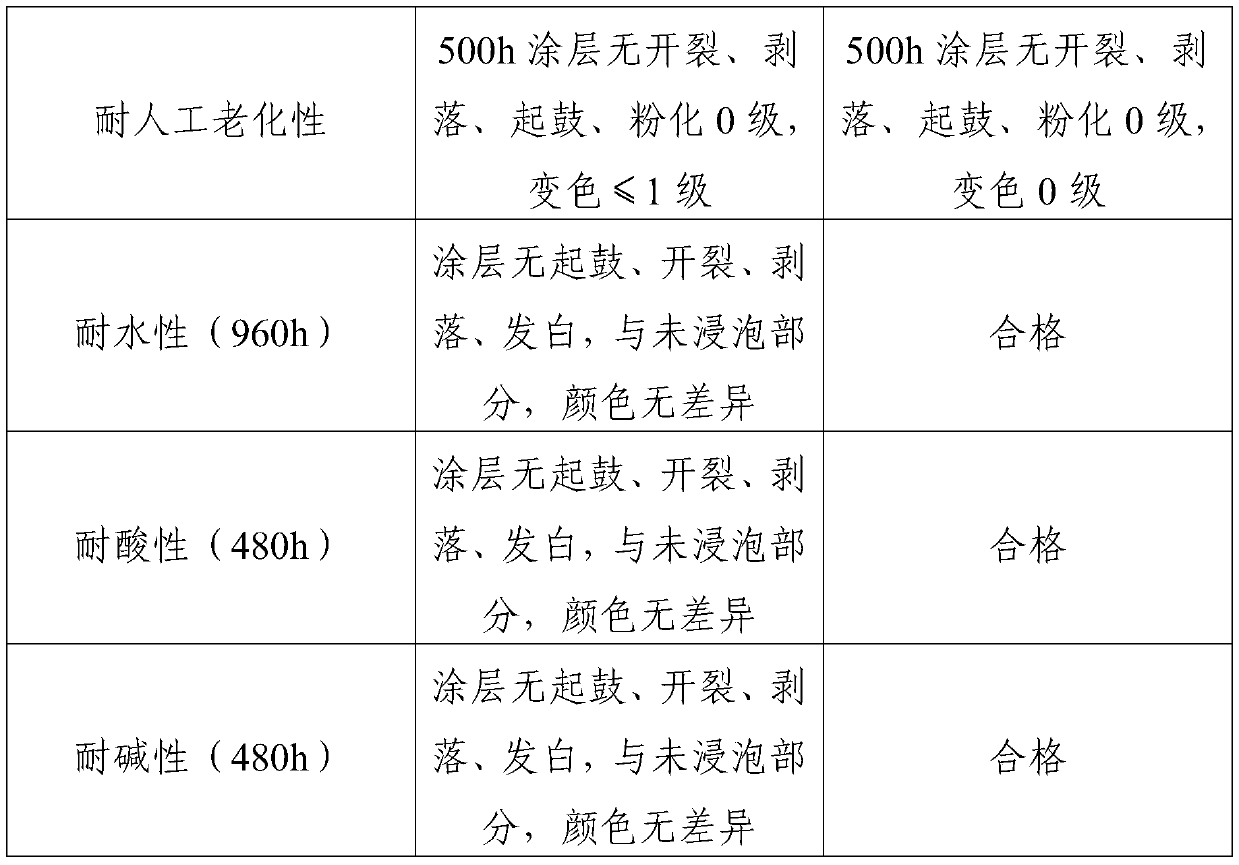

Examples

Embodiment 1

[0033] A kind of high water-resistance real stone paint for building exterior wall is made of the following components in parts by weight:

[0034] 35 parts of silicone acrylic emulsion, 10 parts of polysiloxane modified styrene acrylic emulsion, 3 parts of natural latex, 5 parts of fluorine-containing block copolymer, 55 parts of colored sand, 10 parts of composite rock slice, 5 parts of silica sol, 1 part of organic bentonite 3 parts of wood fiber, 6 parts of polyether modified silicone oil-coated silicon micropowder, 0.01 part of triethanolamine, 3 parts of hydrogenated castor oil, 0.6 part of hydroxypropyl guar gum, 0.1 part of microcrystalline paraffin, alkylphenol polyoxygen 0.1 part of vinyl ether, ethanol, ethylene glycol in a weight ratio of 4:1, antifreeze 0.6 parts, alcohol ester twelve, propylene glycol phenol ether, benzyl alcohol in a weight ratio of 5:1:1 to form a film 1.2 parts of additives, 0.1 parts of BYK-025 defoamer, 10 parts of propylene glycol methyl et...

Embodiment 2

[0040] A kind of high water-resistance real stone paint for building exterior wall is made of the following components in parts by weight:

[0041] 40 parts of silicone acrylic emulsion, 15 parts of polysiloxane modified styrene acrylic emulsion, 2 parts of natural latex, 6 parts of fluorine-containing block copolymer, 50 parts of colored sand, 8 parts of composite rock slice, 2 parts of silica sol, 1 part of organic bentonite 3 parts of wood fiber, 8 parts of polyether modified silicone oil coated silicon micropowder, 0.01 part of triethanolamine, 3 parts of hydrogenated castor oil, 0.6 part of hydroxypropyl guar gum, 0.1 part of microcrystalline paraffin, fatty alcohol polyoxyethylene 0.1 part of ether, ethanol, ethylene glycol mixed in a weight ratio of 4:1 antifreeze 0.8 parts, alcohol ester twelve, propylene glycol phenol ether, benzyl alcohol mixed in a weight ratio of 5:1:1 film-forming aid 1.5 parts of agent, 0.1 part of BYK-025 defoamer, 8 parts of propylene glycol me...

Embodiment 3

[0047] A kind of high water-resistance real stone paint for building exterior wall is made of the following components in parts by weight:

[0048] 40 parts of silicone acrylic emulsion, 10 parts of polysiloxane modified styrene acrylic emulsion, 1.5 parts of natural rubber latex, 5 parts of fluorine-containing block copolymer, 55 parts of colored sand, 6 parts of composite rock slice, 3 parts of silica sol, 0.5 parts of organic bentonite 2 parts of wood fiber, 5 parts of polyether modified silicone oil-coated silicon micropowder, 0.03 part of triethanolamine, 3 parts of hydrogenated castor oil, 0.8 part of hydroxypropyl guar gum, 0.2 part of microcrystalline paraffin, fatty acid polyoxyethylene ether 0.1 part, ethanol, ethylene glycol mixed in a weight ratio of 4:1 antifreeze 0.8 parts, alcohol ester twelve, propylene glycol phenol ether, benzyl alcohol mixed in a weight ratio of 5:1:1 coalescent 1.5 parts, BYK-037 defoamer 0.12 parts, propylene glycol methyl ether 10 parts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com