Colored micro-smoke fireworks bright beads and preparation method thereof

A micro-smoke and color technology, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of physical and mental health hazards of operators, incomplete combustion of adhesives, low production efficiency, etc., to improve viewing performance and preparation method safety. Reliable, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the colored micro-smoke fireworks bright beads of the present invention comprises the following steps:

[0034] Step 1: Plasticizing

[0035] First add water-displacing nitrocellulose, oxidizing agent, and colored luminescent agent into the kneader, then add the solvent dissolved in the stabilizer, start the machine for plasticization after adding the solvent, and alternately carry out the front and reverse operations until the material is plasticized and plasticized. The time is 40min~90min;

[0036] Step 2: Stretching

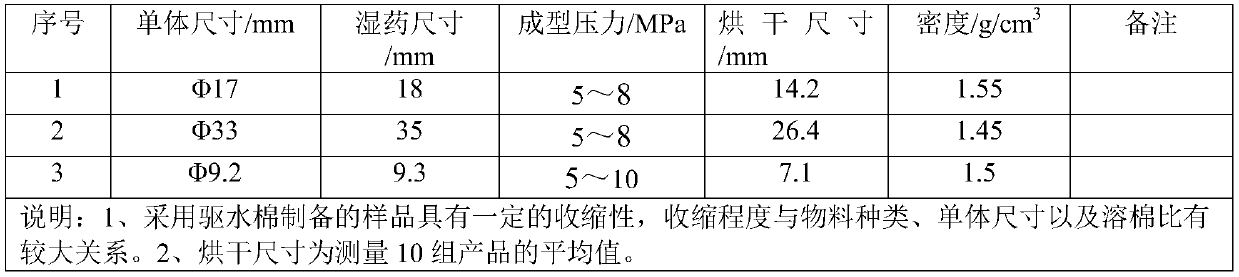

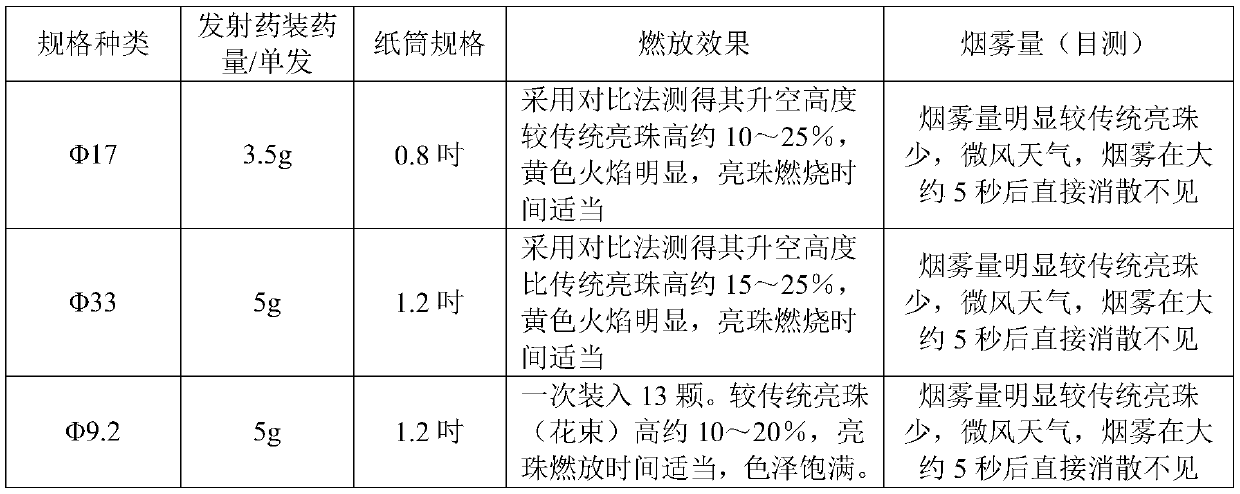

[0037] Compression molding is to press the plasticized material into a certain shape with a hydraulic press or a screw press. The present invention presses the material into a medicine bar through a mold. The outer diameter of the medicine bar is controlled by the inner diameter of the mold forming part (monomer). According to product requirements, generally use a monomer with an inner diameter of 9.2-33mm; the preferred mol...

Embodiment 1

[0047] Water-displacing nitrocellulose, ammonium perchlorate, cryolite are weighed according to the calculated amount, and added in the kneader, the addition of water-displacing nitrocellulose is the total amount of formula materials (water-displacing nitrocellulose, ammonium perchlorate, cryolite, 58% of diphenylamine weight sum), ammonium perchlorate 20%, cryolite 20%, weigh ether and ethanol by dissolving cotton ratio 1.0, solvent ratio 1.0, and add 2% diphenylamine to dissolve. Pour the mixed solvent into the kneader, cover the machine cover, drive the front car for 10 minutes, scrape the cylinder, alternately carry out the front car for 10 minutes, and reverse car for 1 minute, and the plasticizing time is 60 minutes.

[0048] Pour out the plasticized material, divide the material into three parts, seal them well, and add them to the assembled molding mold one after another (the inner diameters of the monomers are 17mm, 33mm, and 9.2mm during the three moldings, add a seal...

Embodiment 2

[0059] The difference from Example 1 is that the solvent used in Example 2 is alcohol and ethyl acetate, and the plasticized material described in Example 2 is added to the single-screw extruder, and assembled at the head of the screw press in advance. The forming mold is completed, and the inner diameter Φ17mm and Φ9.2mm are used for single molding. The operation steps after forming are the same as in Example 1. The size of the sample formed by screw pressing is not much different from that of the hydraulic forming sample, the density is close, and the discharge effect is similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com