Preparation method of integrated electrode composite material and flexible super capacitor

A composite material and supercapacitor technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of weak electrochemical performance, reduced device performance, large interface contact resistance, etc., to achieve good electrochemical performance, The effect of promoting the diffusion rate and accelerating the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

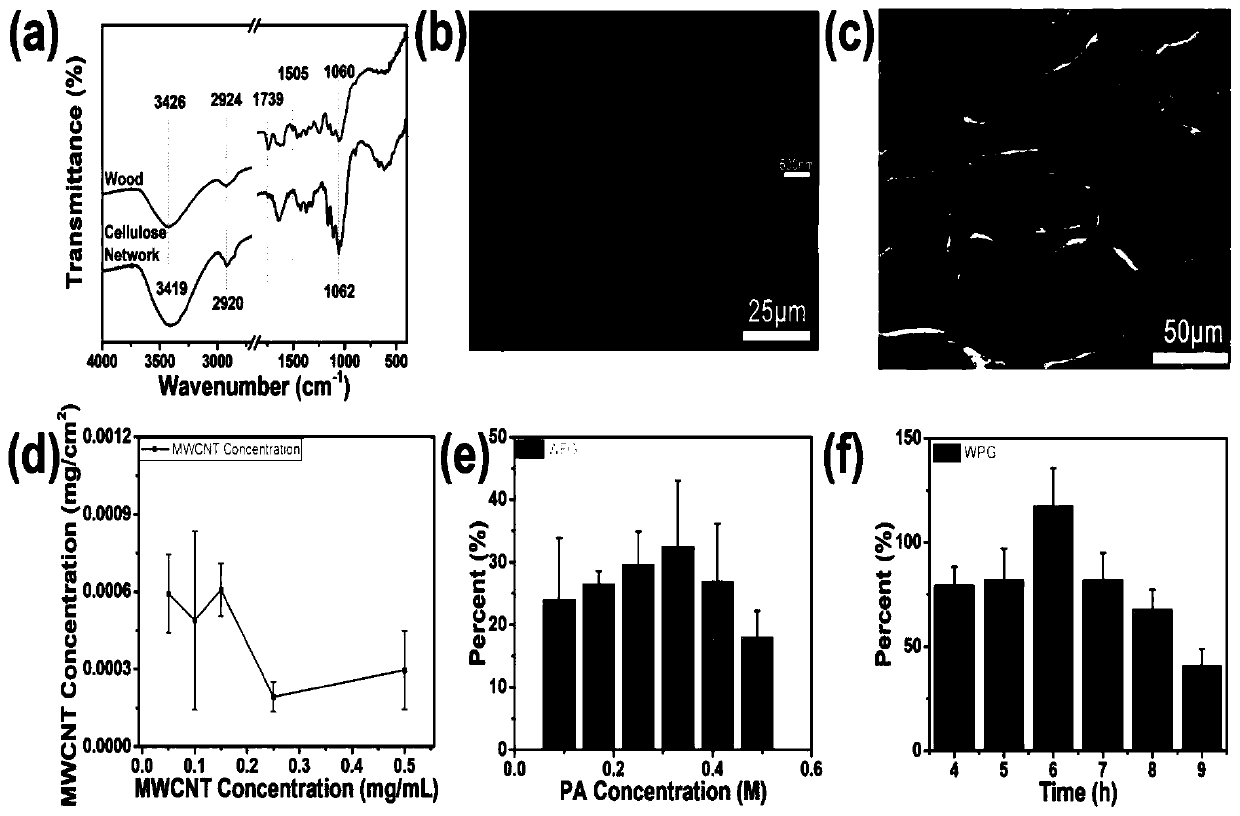

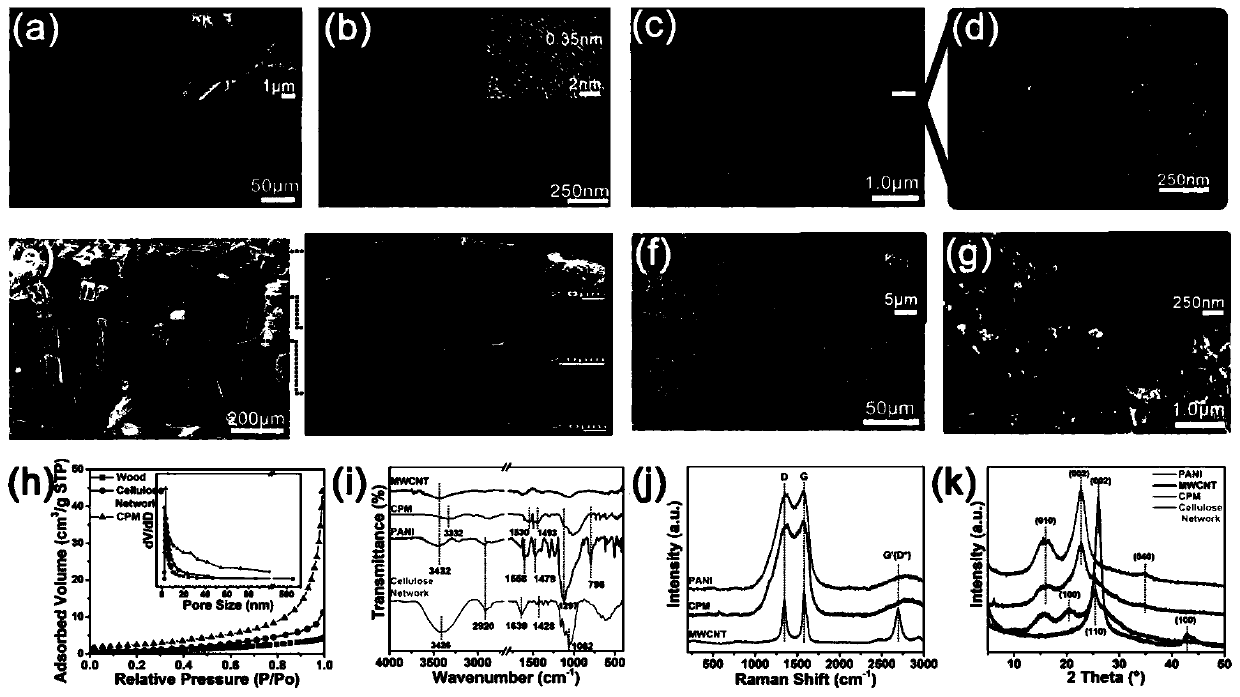

[0045] Take 2g of balsa wood sample (15×15×1mm) and soak it in 50mL of 2.5mol / L KOH aqueous solution, and place it at room temperature at 20-25°C for 12h. Then reflux at 90°C and stir for 3 hours to make the solution system heated evenly, so as to remove most of the hemicellulose and part of the lignin. The samples were then rinsed repeatedly with deionized water until pH=7. Put the treated sample into a 150mL Erlenmeyer flask, and add 65mL of deionized water, 0.5mL of glacial acetic acid, and 0.7g of sodium chlorite in sequence. Then, the mixture was heated at 75 °C for 1 h, and then 0.5 mL of glacial acetic acid and 0.7 g of sodium hypochlorite were added. Repeat the previous step 3 times to obtain a white, component-separated wood sample (white cellulose network block). The prepared samples were rinsed repeatedly with deionized water until pH = 7, and then stored in absolute ethanol for future use.

[0046] Vacuum impregnation of multi-walled carbon nanotubes (MWCNT) and...

Embodiment 2

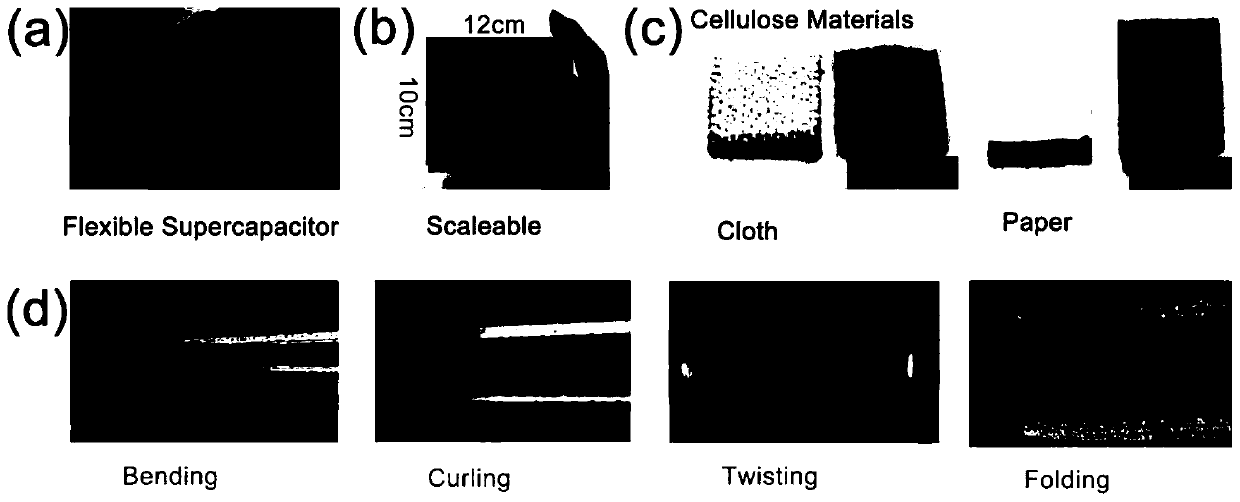

[0048] The CPM composite material obtained in Example 1 was vacuum-immersed in the prepared gel electrolyte for 0.5 h. The gel electrolyte is a polyvinyl alcohol / phosphoric acid gel electrolyte prepared with a mass ratio of PVA: phosphoric acid: water = 1:1:10. Then take out the adhesion of the electrolyte, and coat the MWCNT on the surface of the CPM composite material, and the coating amount of the MWCNT is 0, 2.2, 4.4, 6.6mg / cm 2 , and the corresponding electrode samples were named CPM 0 、CPM 1 、CPM 2 、CPM 3 . in CPM X(CPM0、CPM1、CPM2、CPM3) The surface of the electrode sample is respectively bonded with two carbon cloths with gel electrolyte as a current collector, and various CPMs are assembled. X corresponding supercapacitors. After 3 cycles of freezing and thawing treatment, the freezing and thawing time of each cycle is 12 hours at -20°C and 3 hours at room temperature, and finally the different CPM based on the present invention is obtained. X Composite flexible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Area capacitance | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com