Perovskite type solar cell based on cooperative post-processing of multiple ammonium salts and preparation method thereof

A solar cell, perovskite-type technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems that perovskite films will not reach the film quality, reduce non-radiative recombination, etc., and improve the open circuit voltage and fill factor. , the effect of reducing non-radiative recombination and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

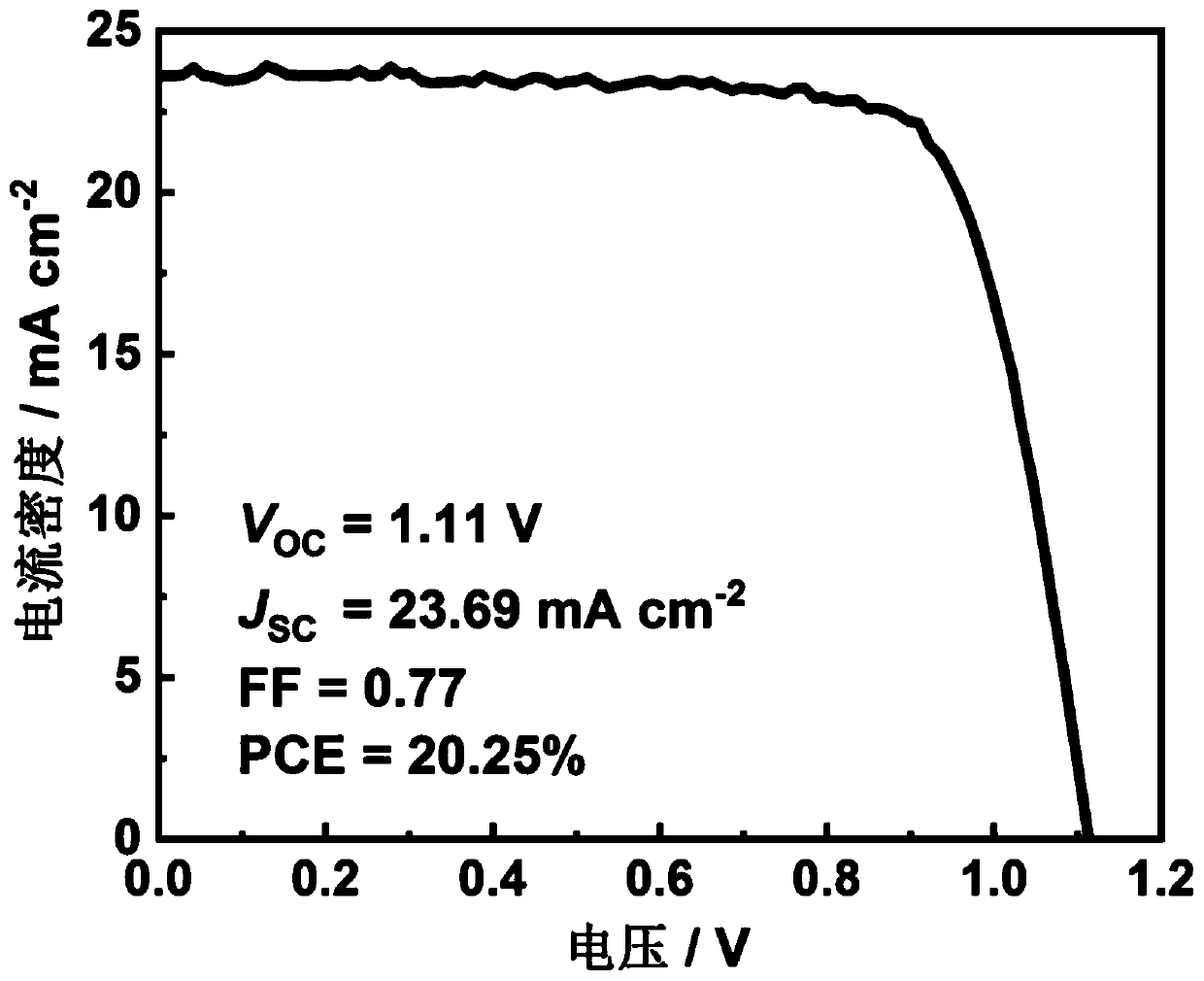

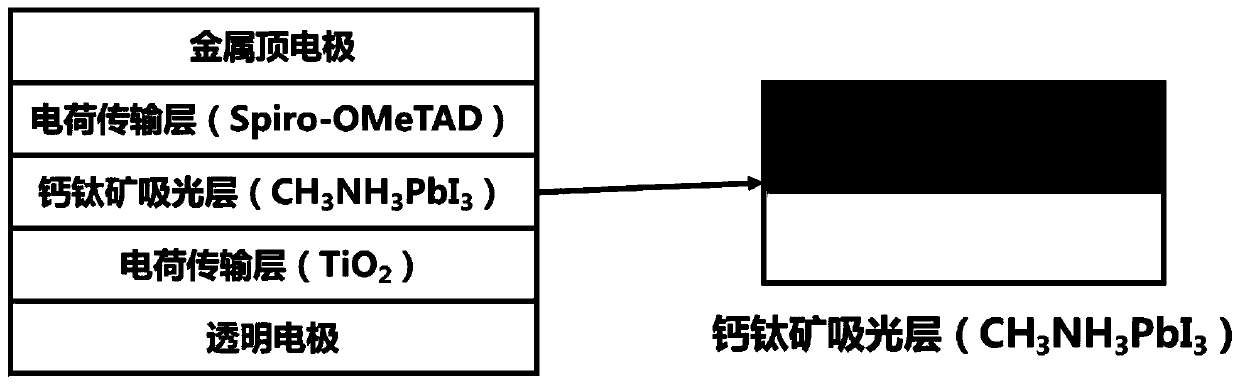

Embodiment 1

[0028] In the first step, use deionized water, acetone, optical glass cleaner, deionized water, and isopropanol to ultrasonically clean the FTO glass substrate (15Ω / □), dry it in an oven at 60°C for 4 hours, and then use 5 mg / mL TiO 2 Colloidal TiO 2 The colloidal quantum dots were spin-coated on the FTO substrate at 4000rpm, and the solvent used was deionized water. Subsequently, the substrate was heated and annealed at 150° C. for 30 minutes. After cooling, the TiO 2 The film substrate is transferred to a N-filled 2 glove box to fabricate the perovskite layer.

[0029] In the second step, the TiO 2 The film substrate is transferred to a N-filled 2 glove box to fabricate the perovskite layer. Equivalent amount of PbI 2 and CH 3 NH 3 I was co-dissolved in a mixed solvent of DMF:DMSO=4:1 (volume ratio) to make a precursor solution. After TiO 2 The substrate was spin-coated with the precursor solution, and 300 μL of chlorobenzene was added dropwise as an anti-solvent...

Embodiment 2

[0033] The first two steps are the same as in Example 1, and in the third step, the post-treatment solution composition is 2.5 mg of 2,2'-(ethylenedioxy)diethylamine hydrobromide (EDBEBr) dissolved in every milliliter of isopropanol. 2 ), 2.5 mg phenylammonium bromide (PhABr) and 5 mg guanidine thiocyanate (GuSCN). Then move to a hot stage for annealing at 100°C for 5 minutes to obtain a perovskite light-absorbing layer with gradient distribution of three ammonium salts. All the other steps are the same as in Example 1. The photoelectric conversion efficiency of such perovskite solar cells can reach 20%.

Embodiment 3

[0035] The first step is the same as in Example 1, and in the second step, the chemical composition of the precursor solution for preparing the perovskite layer is (FA 0.95 PB 2.95 ) 0.85 (MAPbBr 3 ) 0.15 . in TiO 2 The substrate was spin-coated with the precursor solution, and 300 μL of chlorobenzene was added dropwise as an anti-solvent during the spin-coating process. After the spin-coating was completed, it was moved to a hot stage for heating and annealing at 100°C for 30 minutes to form a film.

[0036] In the third step, the composition of the post-treatment solution is to dissolve 5 mg of guanidine hydrobromide (GABr) and 5 mg of phenethylammonium iodide (PEAI) per milliliter of isopropanol. Then move to the hot stage for annealing at 100°C for 5 minutes to obtain a perovskite light-absorbing layer with gradient distribution of three substances. All the other steps are the same as in Example 1. The photoelectric conversion efficiency of such perovskite solar cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com