A hybrid composite forward osmosis membrane assisted by dopamine modification and preparation method thereof

A technology of forward osmosis membrane and hybrid composite, which is applied in the field of membrane separation, can solve the problems of low adhesion fastness of polyamide functional layer, low porosity of porous support membrane, small water flux, etc., and solve the problem of interface description , Improve water flux and reduce membrane resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

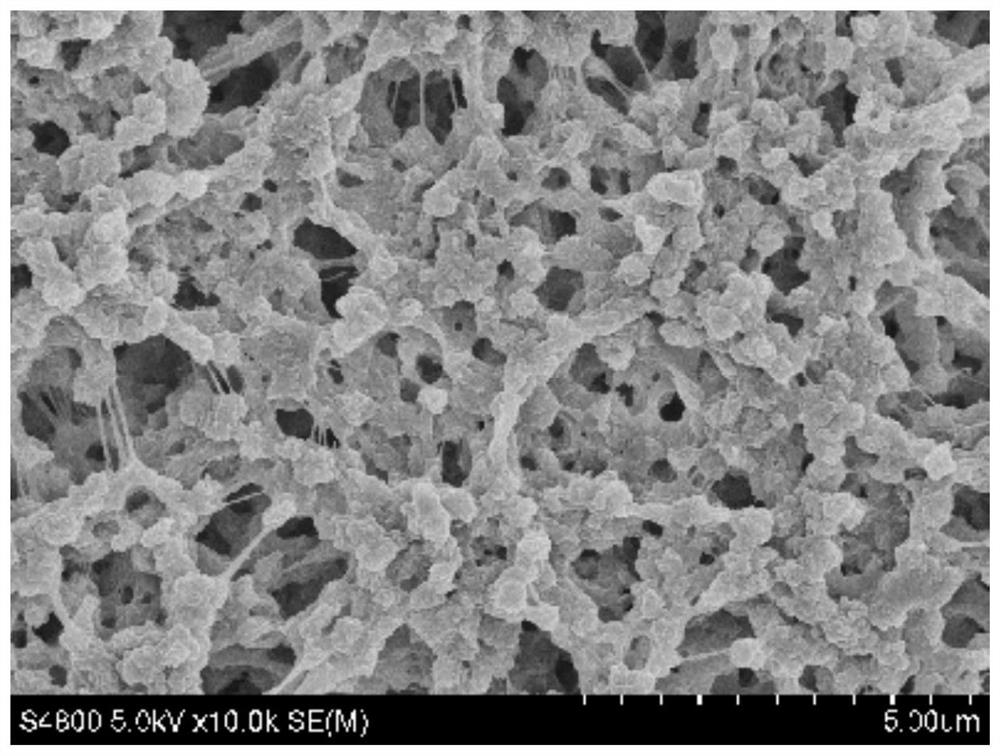

[0024] (1) Add 5g of polyvinylidene fluoride into N-methylpyrrolidone, react at 80°C for 1 hour, then evenly coat it on the surface of the non-woven fabric to obtain a liquid film, and immediately immerse it in a 5g / L sodium chloride solution, The solvent is composed of ethanol and water, the volume ratio of ethanol and water is 9:1, take it out, wash it with deionized water, and obtain a polyvinylidene fluoride support membrane with a micro / nano-scale structure on the surface;

[0025] (2) Immerse the polyvinylidene fluoride membrane in an aqueous solution of 0.2g / L dopamine, 0.05g / L zinc nitrate hexahydrate and 0.2g / L chitosan, soak it at 40°C for 0.5h, and take it out to obtain a primary composite forward osmosis membrane ;

[0026] (3) Immerse the nascent composite forward osmosis membrane in a reactive mixed solution of 5g / L glutaraldehyde and 5g / L 2-methylimidazole, the solvent is composed of methanol and water, and the volume ratio of methanol to water is 9:1, After so...

Embodiment 2

[0030] (1) Add 30g of polyvinylidene fluoride to N,N'-dimethylformamide, react at 80°C for 24 hours, then evenly coat it on the surface of the non-woven fabric to obtain a liquid film, and immediately immerse it in 200g / L chlorine In the potassium chloride aqueous solution, the solvent is composed of ethanol and water, and the volume ratio of ethanol and water is 1:9, taken out, and washed with deionized water to obtain a polyvinylidene fluoride support film with a micro / nano-scale structure on the surface;

[0031] (2) Immerse the polyvinylidene fluoride membrane in an aqueous solution containing 10g / L dopamine, 1g / L zinc nitrate hexahydrate and 10g / L sodium alginate, take it out after soaking at 40°C for 24 hours, and obtain the primary composite forward osmosis membrane;

[0032] (3) Immerse the nascent composite forward osmosis membrane in a reactive mixed solution containing 50g / L sorbitol and 50g / L 2-methylimidazole, the solvent is composed of methanol and water, and the ...

Embodiment 3

[0035] (1) Add 15g of polyvinylidene fluoride to N,N'-dimethylacetamide, react at 80°C for 8 hours, then evenly coat it on the surface of the non-woven fabric to obtain a liquid film, and immediately immerse in 50g / L magnesium chloride In the solution, the solvent is composed of ethanol and water, the volume ratio of ethanol and water is 2:8, taken out, washed with deionized water, and obtained a polyvinylidene fluoride support membrane with a micro / nano-scale structure on the surface;

[0036] (2) Immerse the polyvinylidene fluoride membrane in an aqueous solution containing 1.5g / L dopamine, 0.5g / L zinc nitrate hexahydrate and 2g / L gelatin, take it out after soaking at 40°C for 2 hours, and obtain the primary composite forward osmosis membrane;

[0037] (3) Immerse the nascent composite forward osmosis membrane in a reactive mixed solution containing 10g / L malic acid and 10g / L 2-methylimidazole, the solvent is composed of methanol and water, and the volume ratio of methanol to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com