Iron disulfide doped Mo2S3 porous system as well as preparation method and application thereof

A technology of molybdenum trisulfide and iron disulfide, which is applied in chemical instruments and methods, general water supply conservation, water/sludge/sewage treatment, etc., can solve problems such as instability and low evaporation rate, and achieve low cost and evaporation The effect of high rate and high solar absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

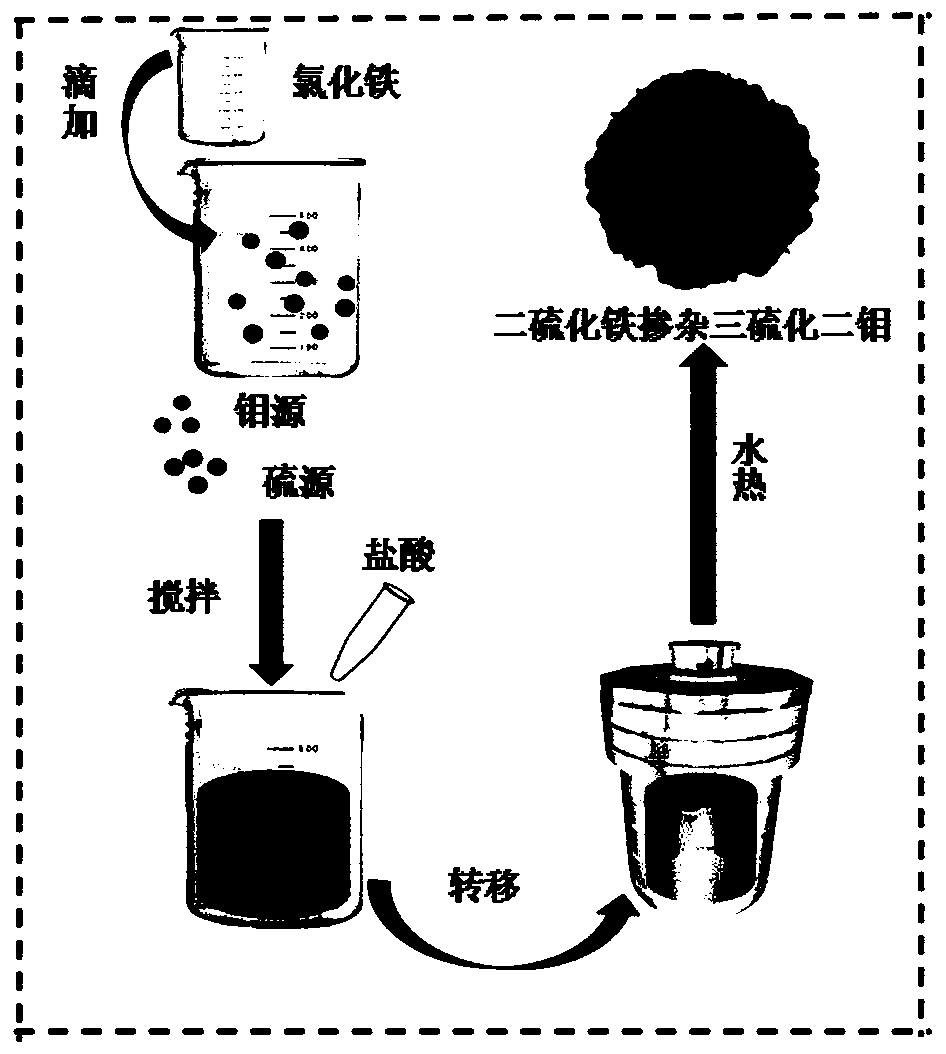

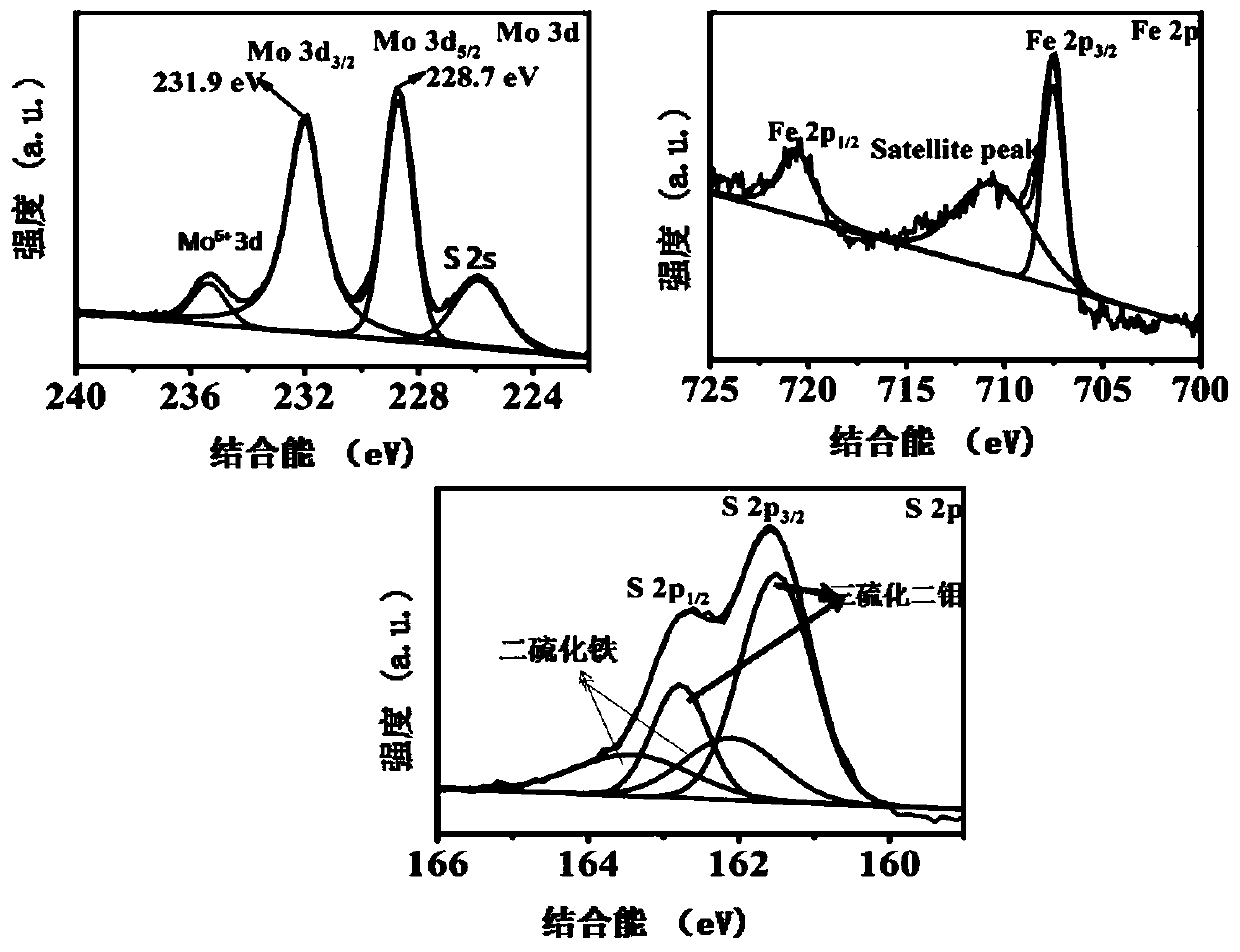

[0053] (1) Preparation of iron disulfide-doped molybdenum trisulfide powder: first prepare 15 mL of 18.2 g / L ferric chloride aqueous solution, then disperse 0.124 g of ammonium molybdate and 0.548 g of thiourea in 15 mL of pure water by magnetic stirring, Then slowly add the prepared ferric chloride solution dropwise into the mixed solution of ammonium molybdate and thiourea, after stirring for 30-60min, add 0.3mL of hydrochloric acid dropwise, continue stirring for 30-60min, and transfer the mixed solution to the reaction kettle. Reaction at 200°C. Reaction finishes cooling to room temperature, water, ethanol centrifugation 4 times, and drying can obtain iron disulfide doped molybdenum trisulfide powder.

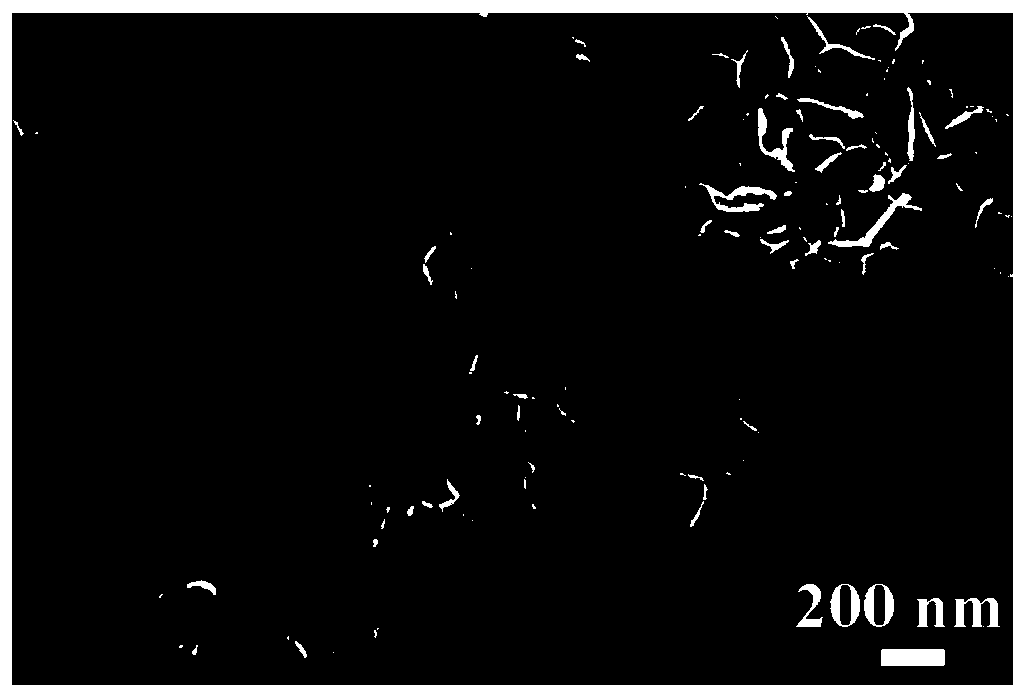

[0054] (2) Preparation of iron disulfide-doped molybdenum trisulfide porous system: ultrasonically disperse 20 mg of the powder obtained in step (1) in 30 mL of water, after the dispersion is uniform, use 0.5 g of sodium alginate as the main raw material of the organic fram...

Embodiment 2

[0056] According to the preparation method of Example 1, just change the high-temperature reaction temperature into 180° C. to obtain the following image 3 of the shape. get as Figure 9 photothermal performance.

Embodiment 3

[0058] Press the preparation method of embodiment 1, just change the high temperature reaction temperature into 190 ℃, obtain as follows image 3 of the shape. get as Figure 9 photothermal performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com