Method for synthesizing MoO3-X antibacterial material with dual mimic enzyme activity

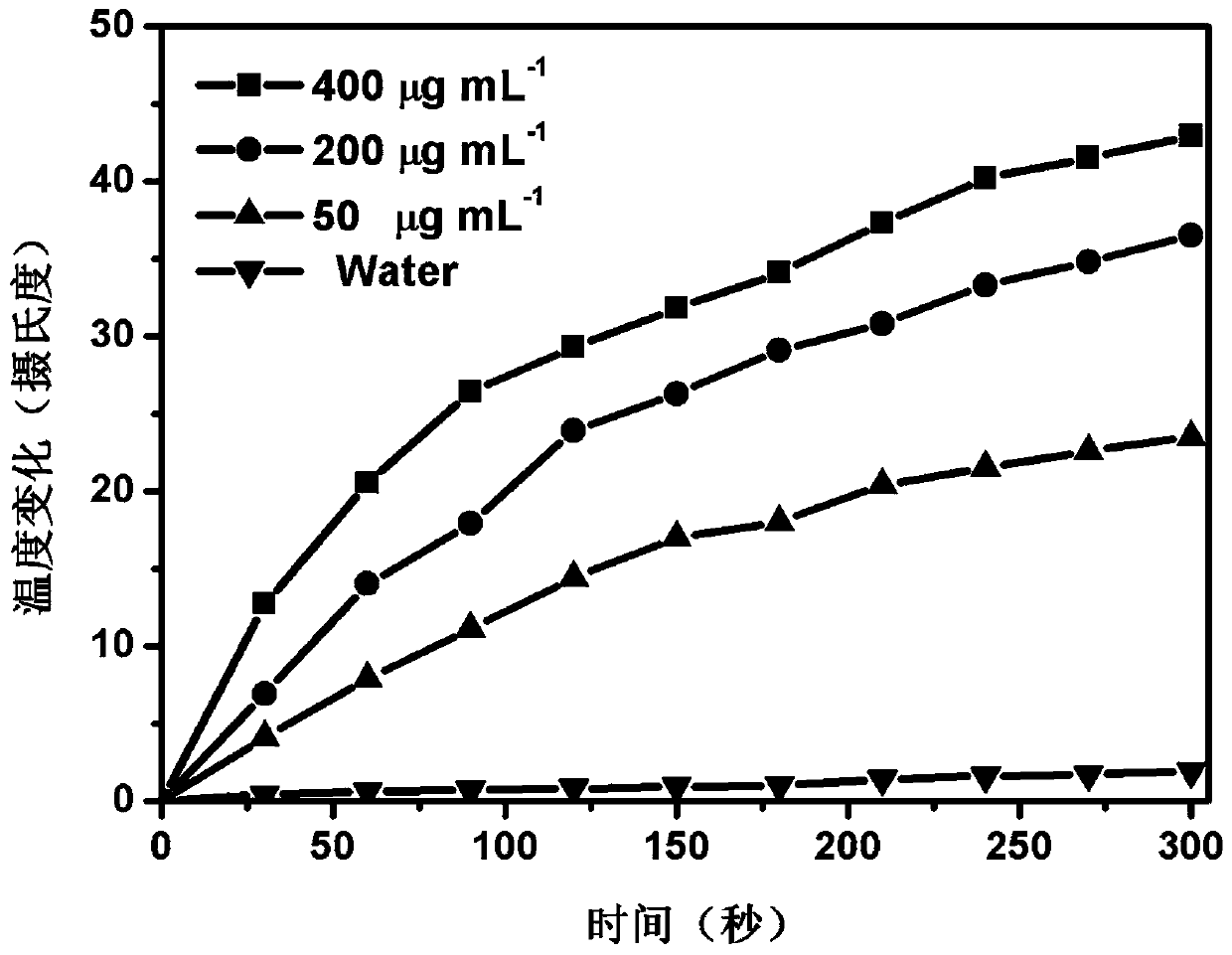

A synthesis method and technology of antibacterial materials, which are applied in the field of synthesizing MoO3-X antibacterial materials with dual enzymatic activity, can solve the problems of no enzymatic activity, carbonization of reductant, and reduction of water solubility, etc., to improve yield and Biocompatibility, easy sterilization, large contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

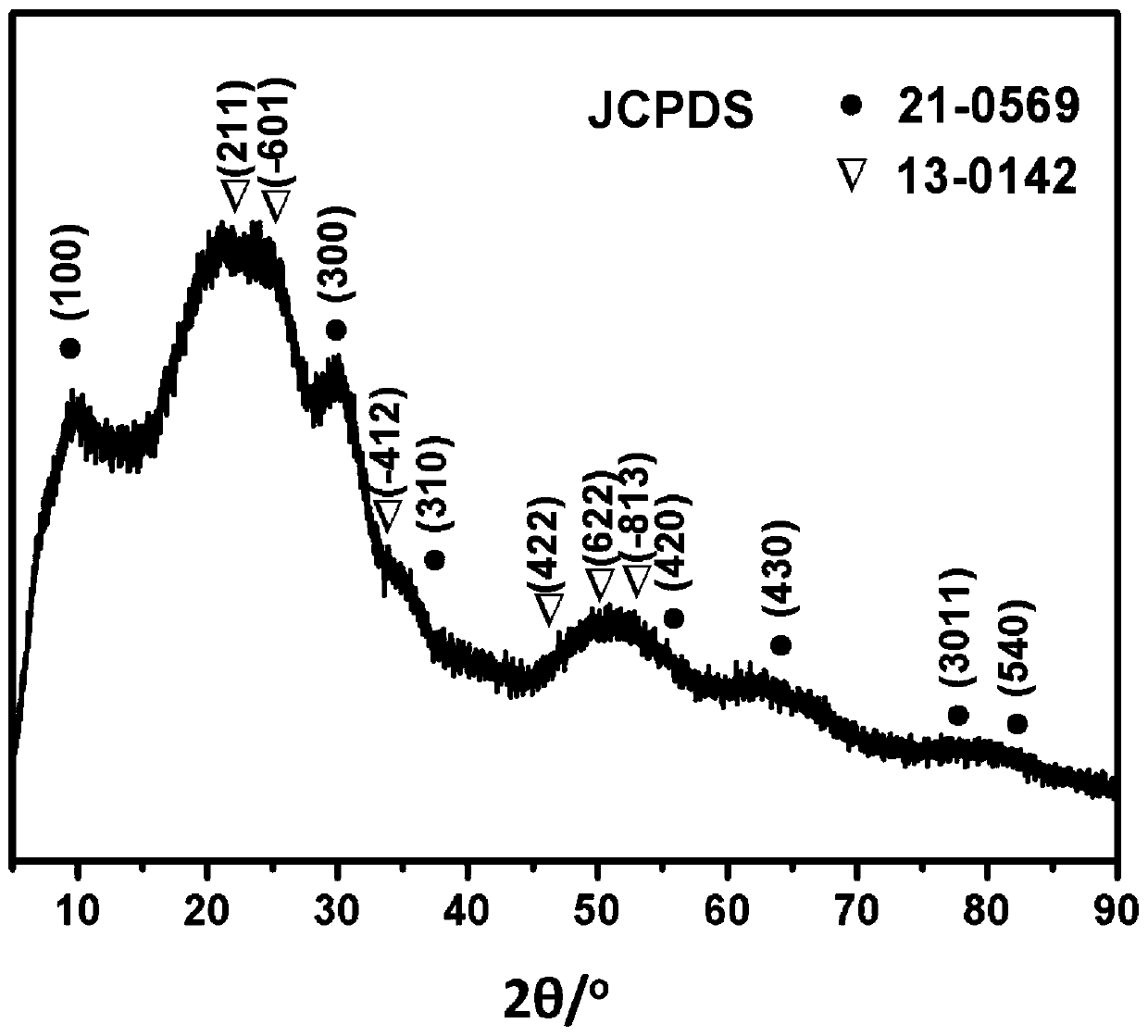

[0034] A kind of synthetic method of the molybdenum oxide antibacterial material with double imitating enzyme activity provided in this embodiment, comprises the following steps:

[0035] S1. Dissolving glucose in water, stirring to dissolve, adding molybdate, and continuing to stir until the molybdate is completely dissolved to obtain a mixed solution;

[0036] S2, adding hydrochloric acid to the mixed solution prepared in S1, adjusting the pH of the mixed solution to be acidic;

[0037] S3. Pour the uniformly stirred mixed solution in S2 into a reaction kettle with a tetrafluoroethylene liner, seal it, and heat it to obtain a blue solution;

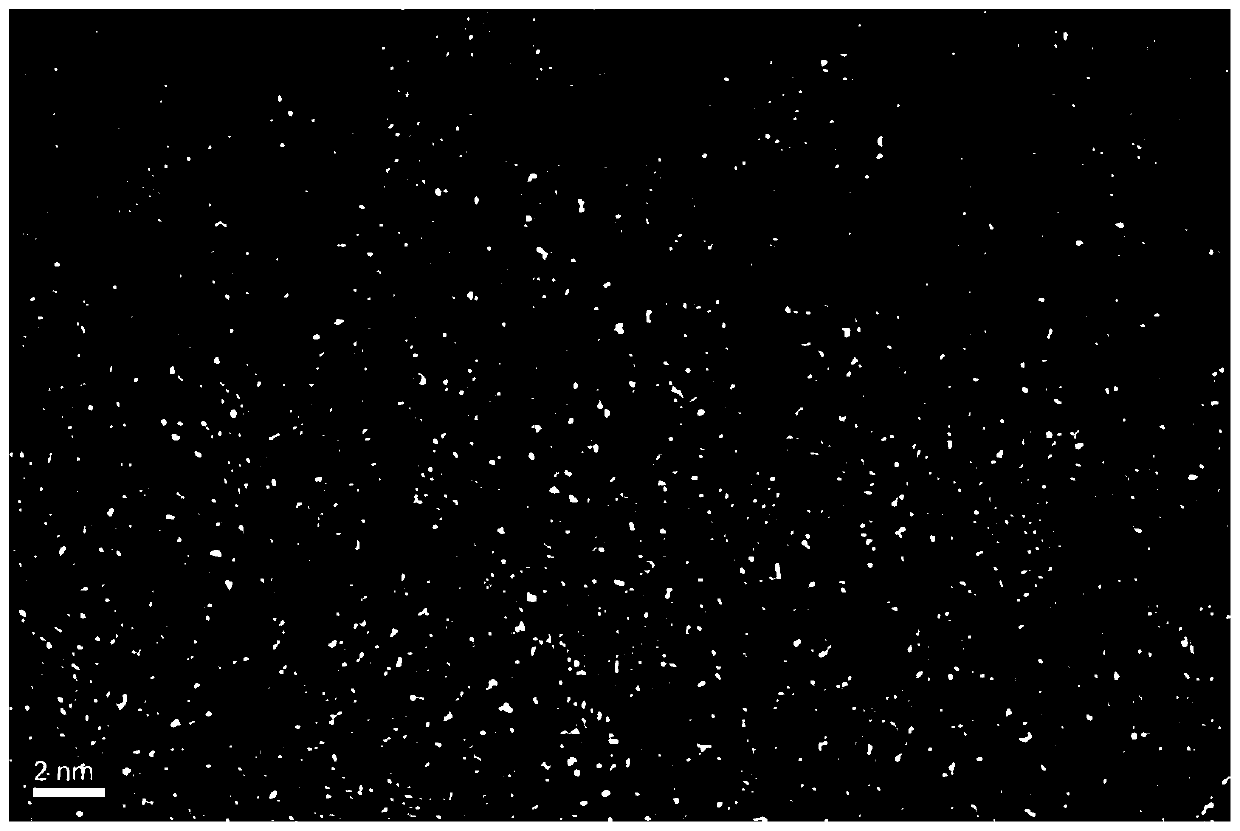

[0038] S4. Dialyze the blue solution with a dialysis bag, and freeze-dry the remaining material after dialysis to obtain nano-MoO 3-X Antibacterial material, sealed and stored away from light.

[0039] Preferably, the mass volume ratio of glucose to water in this embodiment S1 is 0.3-2.0 g: 30 mL.

[0040] Preferably, the mass ratio ...

Embodiment 2

[0047] S1. Dissolve 1.5g glucose and 0.5g ammonium molybdate in 30mL water, stir for 20 minutes until completely dissolved;

[0048] S2. Add hydrochloric acid dropwise to the mixed solution, adjust the pH of the solution to be 4, and then stir for 5 minutes;

[0049] S3, pour the mixed solution into a tetrafluoroethylene reactor and seal it, and heat it at 80 degrees for 12 hours;

[0050] S4. The crude product is poured into a dialysis bag (10Kda dialysis membrane), dialyzed for 48 hours, then freeze-dried, sealed and stored away from light.

Embodiment 3

[0052] Basically the same as embodiment 2, the difference is:

[0053] In the step S1, the mass volume ratio of glucose to water is 1.2g:30mL;

[0054] Described, the mass ratio of glucose and sodium molybdate is 3:1;

[0055] In the step S2, the mixed solution has a pH of 1 and is stirred for 15 minutes;

[0056] In the step S3, the hydrothermal reaction temperature is 80 degrees, and the reaction is carried out for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com