Normal-temperature modified sludge dehydrating agent and preparation method thereof

A dehydrating agent and modification technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc. problem, to achieve the effect of improving filter press dehydration performance, low cost and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

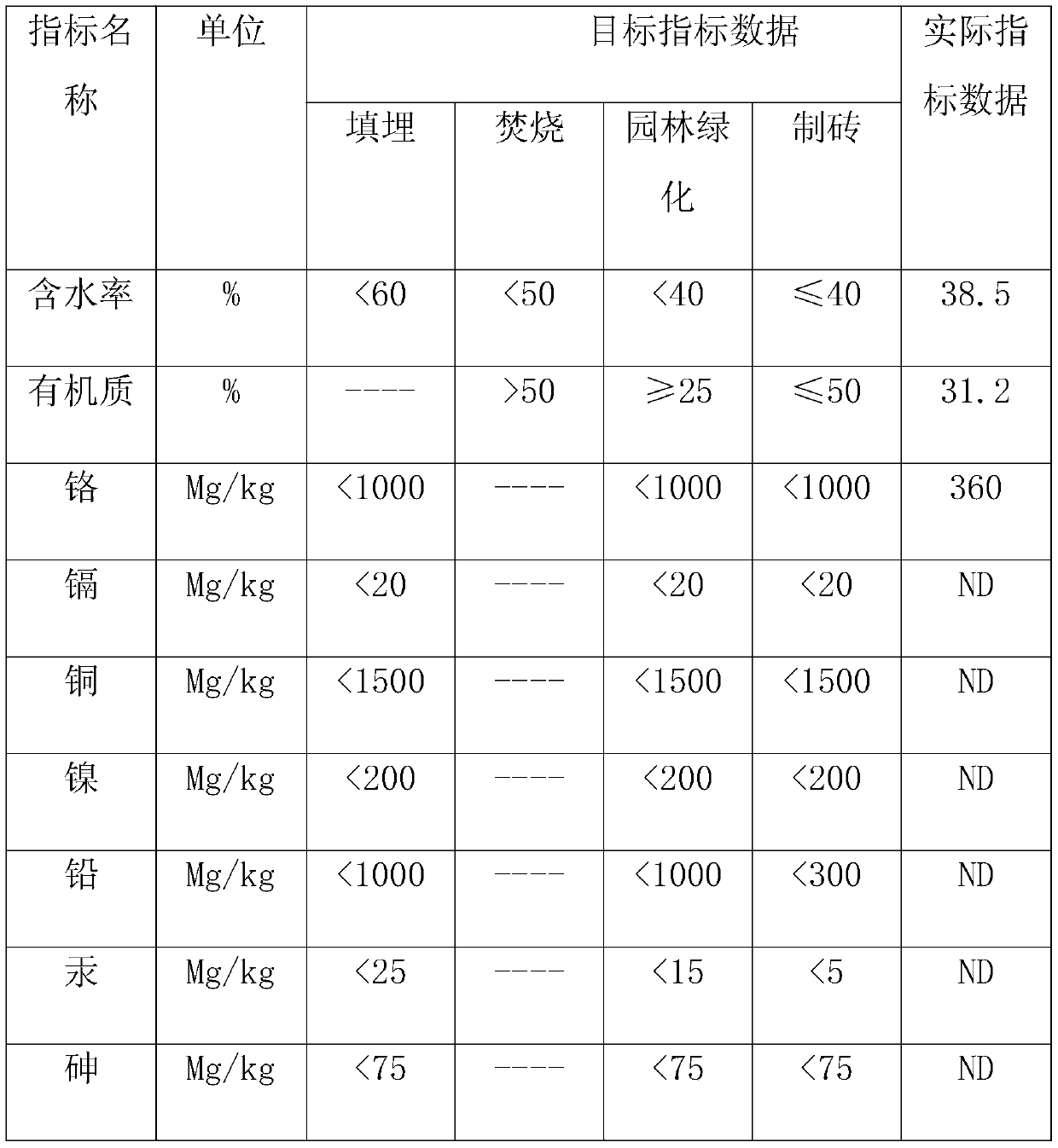

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of normal temperature modified sludge dewatering agent provided by the present embodiment comprises 20 parts of calcium oxide, 15 parts of ferric chloride, 30 parts of modified starch, 15 parts of diatomaceous earth, 5 parts of volcanic rock, 20 parts of gelatin, 5 parts of volcanic rock by weight. 1 part of polyacrylamide, 1 part of bentonite, 2 parts of talcum powder, 2 parts of muck and 1 part of chitosan.

[0017] The iron salt is one or more of ferric chloride, vitriol and ferric sulfate.

[0018] The molecular weight of the polyacrylamide is 6-18 million.

[0019] The preparation method is to mix 20 parts of calcium oxide, 15 parts of ferric chloride, 30 parts of modified starch, 15 parts of diatomaceous earth, 5 parts of volcanic rock, 20 parts of gelatin, 5 parts of polyacrylamide, 1 part of bentonite, and 2 parts of talcum powder , 2 parts of slag and 1 part of chitosan were added to the polymerization kettle, stirred by magnetic force for 15-20 minutes...

Embodiment 2

[0021] A kind of normal temperature modified sludge dewatering agent provided by the present embodiment comprises 25 parts of calcium oxide, 18 parts of ferric chloride, 35 parts of modified starch, 18 parts of diatomaceous earth, 8 parts of volcanic rock, 25 parts of gelatin, 10 parts by weight. 1 part of polyacrylamide, 2 parts of bentonite, 2 parts of talcum powder, 3 parts of muck and 2 parts of chitosan.

[0022] The iron salt is one or more of ferric chloride, vitriol and ferric sulfate.

[0023] The molecular weight of the polyacrylamide is 6-18 million.

[0024] The preparation method is to first mix 25 parts of calcium oxide, 18 parts of ferric chloride, 35 parts of modified starch, 18 parts of diatomaceous earth, 8 parts of volcanic rock, 2 parts of bentonite, 2 parts of talcum powder, 3 parts of slag and 2 parts of chitosan Add sugar into the polymerization kettle, stir magnetically for 15-20 minutes, then add 25 parts of gelatin and 10 parts of polyacrylamide, rea...

Embodiment 3

[0026] A kind of normal temperature modified sludge dewatering agent provided in this embodiment comprises 30 parts of calcium oxide, 20 parts of ferric chloride, 40 parts of modified starch, 20 parts of diatomaceous earth, 10 parts of volcanic rock, 30 parts of gelatin, 10 parts by weight. 1 part of polyacrylamide, 2 parts of bentonite, 3 parts of talcum powder, 5 parts of muck and 3 parts of chitosan.

[0027] The iron salt is one or more of ferric chloride, vitriol and ferric sulfate.

[0028] The molecular weight of the polyacrylamide is 6-18 million.

[0029] The preparation method is to first mix 30 parts of calcium oxide, 20 parts of ferric chloride, 40 parts of modified starch, 20 parts of diatomaceous earth, 10 parts of volcanic rock, 2 parts of bentonite, 3 parts of talcum powder, 5 parts of slag and 3 parts of chitosan Add sugar into the polymerization kettle, stir magnetically for 15-20 minutes, then add 30 parts of gelatin and 10 parts of polyacrylamide, react fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com