A kind of cellulase suitable for preparing cellulose nanocrystal and its application

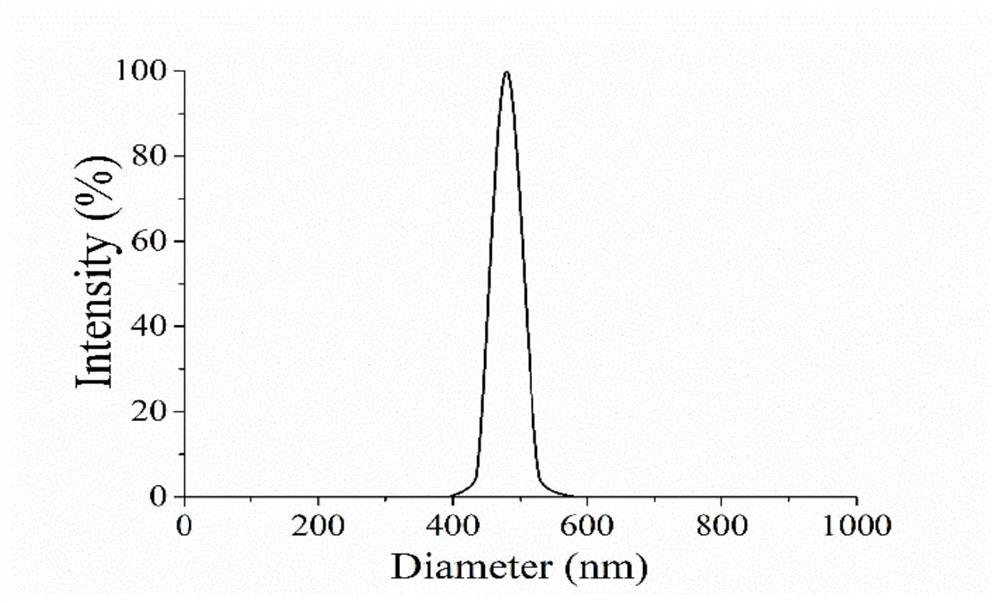

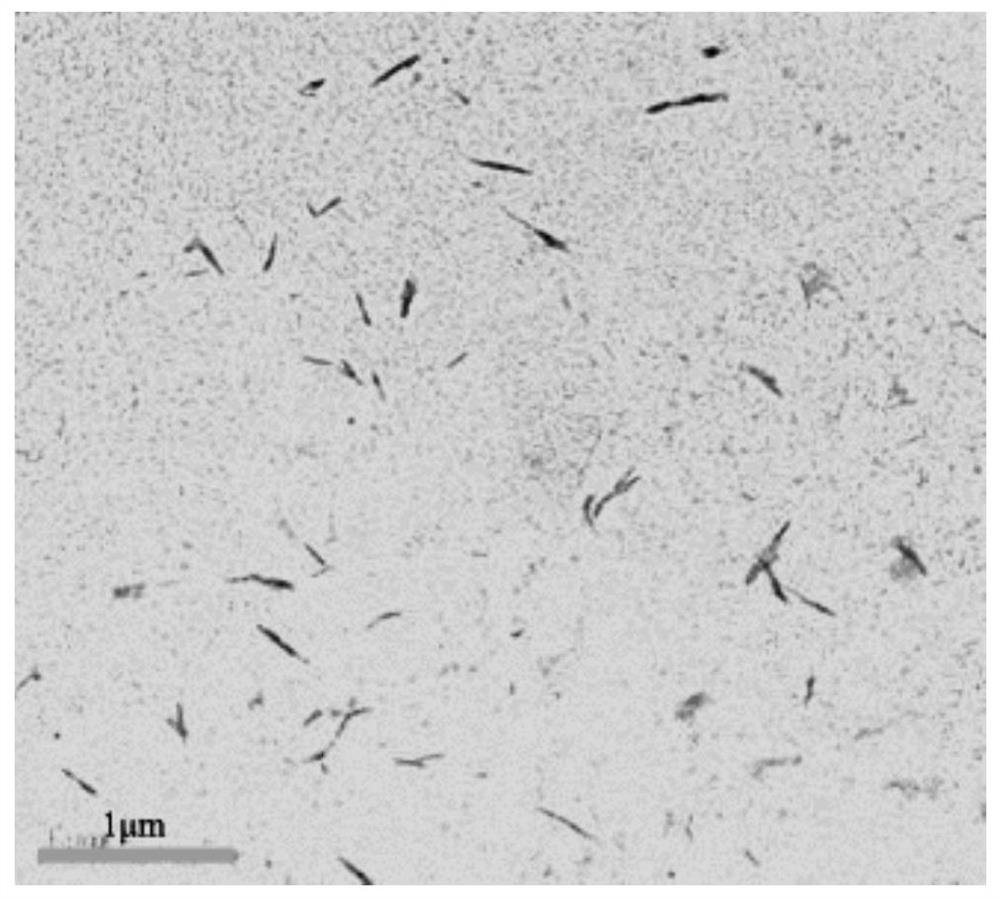

A technology of cellulase and nanocrystals, which is applied in the biological field to achieve the effects of small particle size, high hydrolysis efficiency, and accelerated fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The construction of embodiment 1 engineering strain cEES

[0064] (1) Gene acquisition:

[0065]The activation of the cellulase gene (cbh1) (GenBank: GQ844299.1) was amplified with primers cbh1-U-F and cbh1-U-R using Penicillium oxalicum CGMCC No.5302 genome (GenBank: AGIH00000000.1) as a template Subsequence cbh1 (U), amplified with primers cbh1-D-hphR-F and cbh1-D-R to obtain the downstream sequence cbh1 (D) of the cellulase gene (cbh1) coding region, with primers Cel7B-cbh1 (U) R-F and Cel7B-hphF-R amplifies the gene fragment cel7B (GenBank: EU339127.1), and uses primers cel5B-F and cel5B-R to amplify the gene fragment cel5B (GenBank: KJ 955479); with Trichoderma reesei The cDNA of QM6a ATCC13631 (GenBank: AAIL00000000.2) was used as a template to amplify the gene swo1 (GenBank: AJ245918.1) with primers swo1-AgpdA(p)R-F and swo1-R; the plasmid pAN7-1 (GenBank: Z32698.1 ) was used as a template to amplify the promoter AgpdA( p)(GenBank:Z32524.1); the glyceraldehyde...

Embodiment 2

[0102] After the engineering strain cEES is activated, the seed liquid is obtained. Under sterile conditions, the hyphae are added to the fermentation medium in a proportion of 0.3% by weight, and cultured at 28°C and 250rpm for 7 days or in a fermenter for 7 days; Obtain the supernatant by centrifugation (10000rpm, 10min), which is the cellulase-containing fermentation broth. In the cellulase liquid, the ratio of endo-cellulase activity to exo-enzyme activity is 40, and the protein ratio of endo-cellulase Cel7B to Cel5B is 1.

[0103] Among them: the seed medium formula is: 20g / L glucose, Vogel's salt; the fermentation medium formula is: 10g / L bran, 10g / L microcrystalline cellulose, 3g / L KH 2 PO 4, 2.6g / L NaNO 3 , 0.5g / LMgSO 4 ·7H 2 O, 0.5g / L CaCl 2 , 1g / Lpeptone, 7.5mg / L FeSO 4 ·7H 2 O, 2.5mg / L MnSO 4 ·H 2 O, 3.6mg / L ZnSO 4 ·7H 2 O, 3.7mg / LCoCl 2 ·6H 2 O.

[0104] The formula of the above-mentioned Vogel's salt has been recorded and publicized in Chinese patent...

Embodiment 3

[0106] After the engineering strain cEES is activated, the seed liquid is obtained. Under sterile conditions, the hyphae are added to the fermentation medium in a proportion of 2% by weight, and cultivated at 35°C and 150rpm for 3 days or in a fermenter for 3 days; Obtain the supernatant by centrifugation (10000rpm, 10min), which is the cellulase-containing fermentation broth. In the cellulase liquid, the ratio of endo-cellulase activity to exo-enzyme activity was 44, and the protein ratio of endo-cellulase Cel7B to Cel5B was 1.1.

[0107] Among them: the seed medium formula is: 20g / L glucose, Vogel's salt; the fermentation medium formula is: 10g / L bran, 10g / L microcrystalline cellulose, 3g / L KH 2 PO 4 , 2.6g / L NaNO 3 , 0.5g / LMgSO 4 ·7H 2 O, 0.5g / L CaCl 2 , 1g / Lpeptone, 7.5mg / L FeSO 4 ·7H 2 O, 2.5mg / L MnSO 4 ·H 2 O, 3.6mg / L ZnSO 4 ·7H 2 O, 3.7mg / LCoCl 2 ·6H 2 O.

[0108] The formula of the above-mentioned Vogel's salt has been recorded and publicized in Chinese p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com