Grinding wheel for machining PCD blade

A grinding wheel and blade technology, which is applied in metal processing equipment, abrasives, manufacturing tools, etc., can solve the problems of fast wear of dressing tools, increase production cost, and affect production efficiency, so as to improve processing efficiency, service life, and single Tablet consumption less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

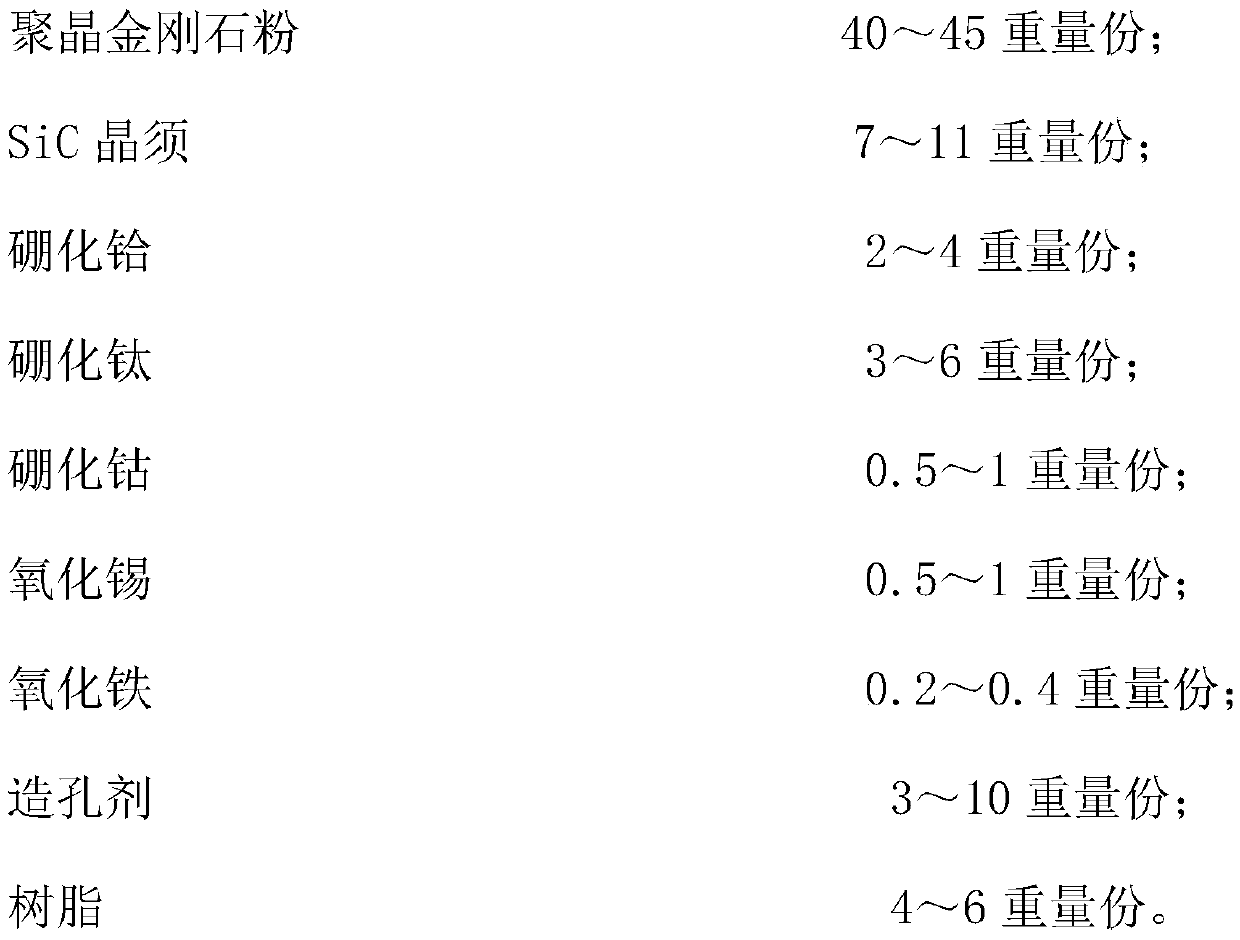

[0036] A grinding wheel for processing PCD blades, comprising a grinding wheel substrate, the grinding wheel substrate is provided with a grinding layer in turn, the grinding wheel substrate is provided with a wear-resistant layer, and the grinding layer includes the following components in parts by weight:

[0037]

[0038]

[0039] The particle size of polycrystalline diamond powder is 200 mesh; the aspect ratio of SiC whiskers is 7:1; the particle size of hafnium boride, titanium boride, cobalt boride, tin oxide and iron oxide is 30 μm; the pore forming agent is hollow Glass microspheres; the resin includes 3 parts by weight of epoxy resin modified polyurethane, 2 parts by weight of polyimide resin and 0.5 part by weight of ABS resin.

[0040] The wear layer consists of the following components:

[0041] Tantalum carbide: 30 parts; Ti 3 SnC 2 10 parts; 4 parts of molybdenum; 23 parts of furan resin; 10 parts of silicone resin; 0.5 parts of β-hydroxyalkylamide, 0.5 ...

Embodiment 2

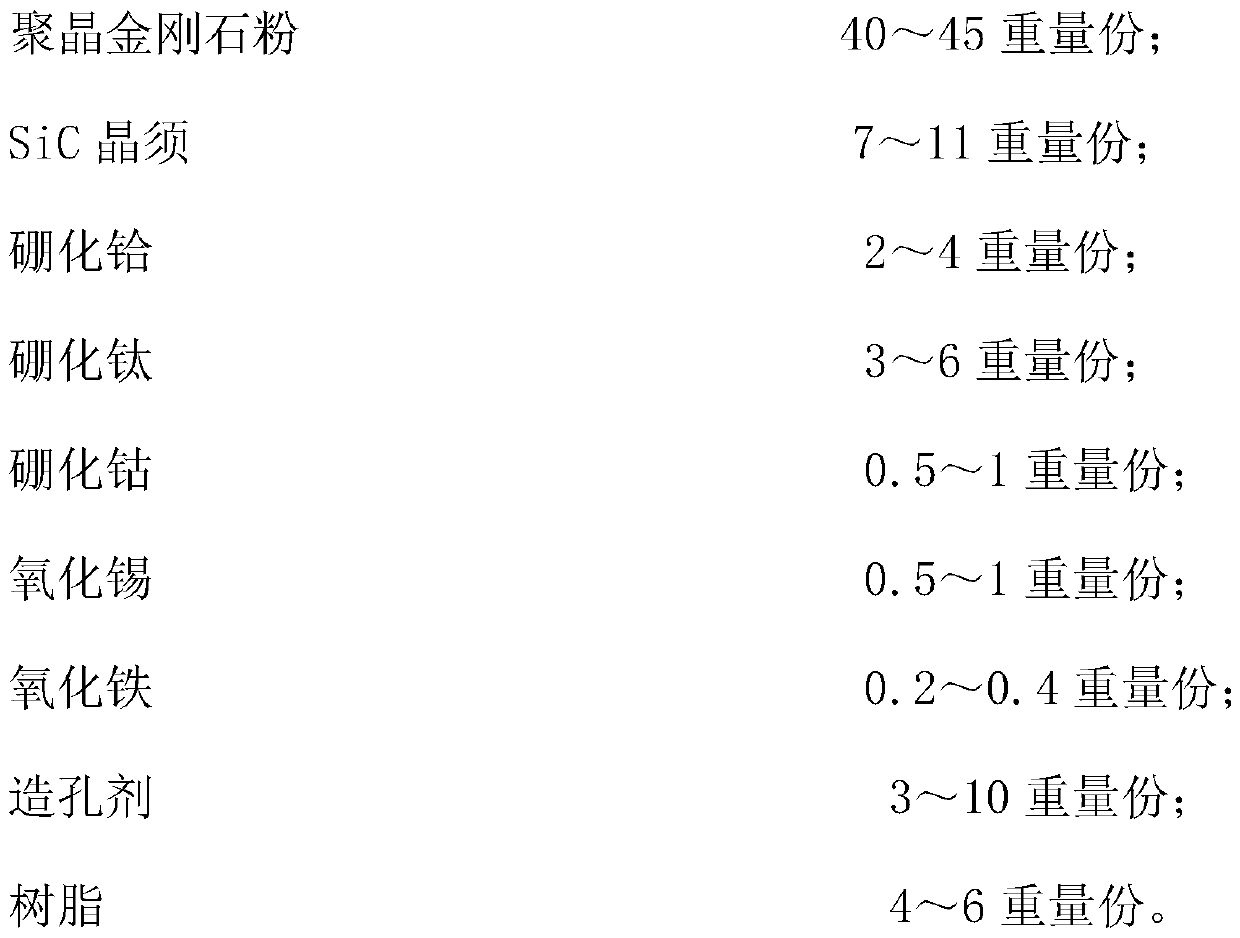

[0043] A grinding wheel for processing PCD blades, comprising a grinding wheel substrate, the grinding wheel substrate is provided with a grinding layer in turn, the grinding wheel substrate is provided with a wear-resistant layer, and the grinding layer includes the following components in parts by weight:

[0044]

[0045] The particle size of polycrystalline diamond powder is 200 mesh; the aspect ratio of SiC whiskers is 8:1; the particle size of hafnium boride, titanium boride, cobalt boride, tin oxide and iron oxide is 40 μm; the pore-forming agent is PS ; The resin comprises 4 parts by weight of epoxy resin modified polyurethane, 3 parts by weight of polyimide resin and 0.6 part by weight of ABS resin;

[0046] The wear layer consists of the following components:

[0047] Tantalum carbide: 35 parts; Ti 3 SnC 2 11 parts; 5 parts of molybdenum; 24 parts of furan resin; 11 parts of silicone resin; 1 part of β-hydroxyalkylamide, 0.7 part of 2-phenylimidazoline; 3 SnC ...

Embodiment 3

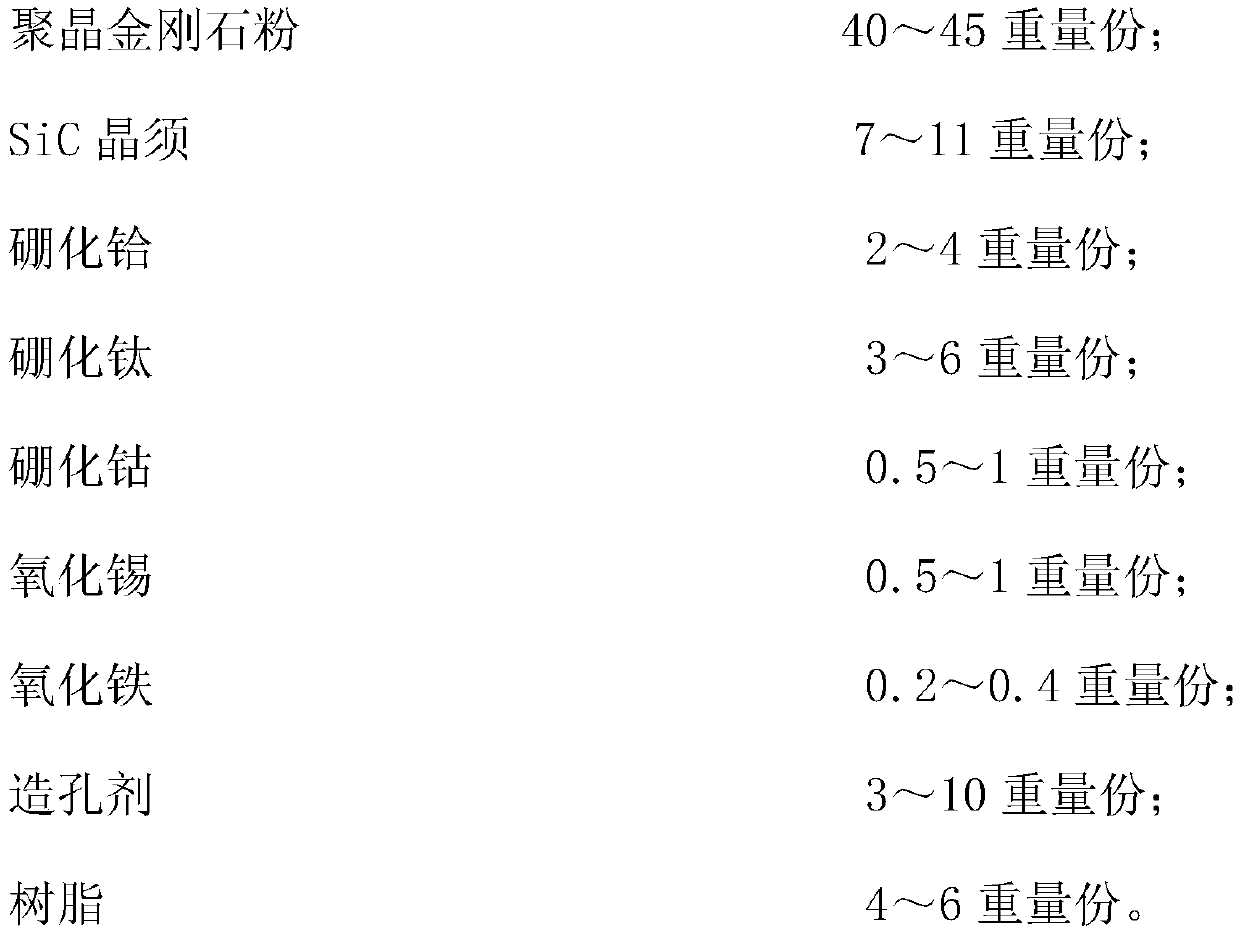

[0049]A grinding wheel for processing PCD blades, comprising a grinding wheel substrate, the grinding wheel substrate is provided with a grinding layer in turn, the grinding wheel substrate is provided with a wear-resistant layer, and the grinding layer includes the following components in parts by weight:

[0050]

[0051] The particle size of polycrystalline diamond powder is 400 mesh; the aspect ratio of SiC whiskers is 10:1; the particle size of hafnium boride, titanium boride, cobalt boride, tin oxide and iron oxide is 50 μm; the pore forming agent is carbonic acid Sodium; the resin includes 5 parts by weight of epoxy resin modified polyurethane, 4 parts by weight of polyimide resin and 1 part by weight of ABS resin.

[0052] The wear layer consists of the following components:

[0053] Tantalum carbide: 40 parts; Ti 3 SnC 2 12 parts; molybdenum 7 parts; furan resin 25 parts; silicone resin 12 parts; β-hydroxyalkylamide 2 parts, 1 part 2-phenylimidazoline; tantalum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com