A zirconium-free anorthite-based opacified glaze and preparation method thereof

An opaque glaze and anorthite technology, applied in the field of ceramic glaze, can solve problems such as damage to consumers' health, excessive radioactivity of products, easy yellowing of the glaze surface, etc., and achieve the advantages of promotion and application, low cost, and scope of application. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

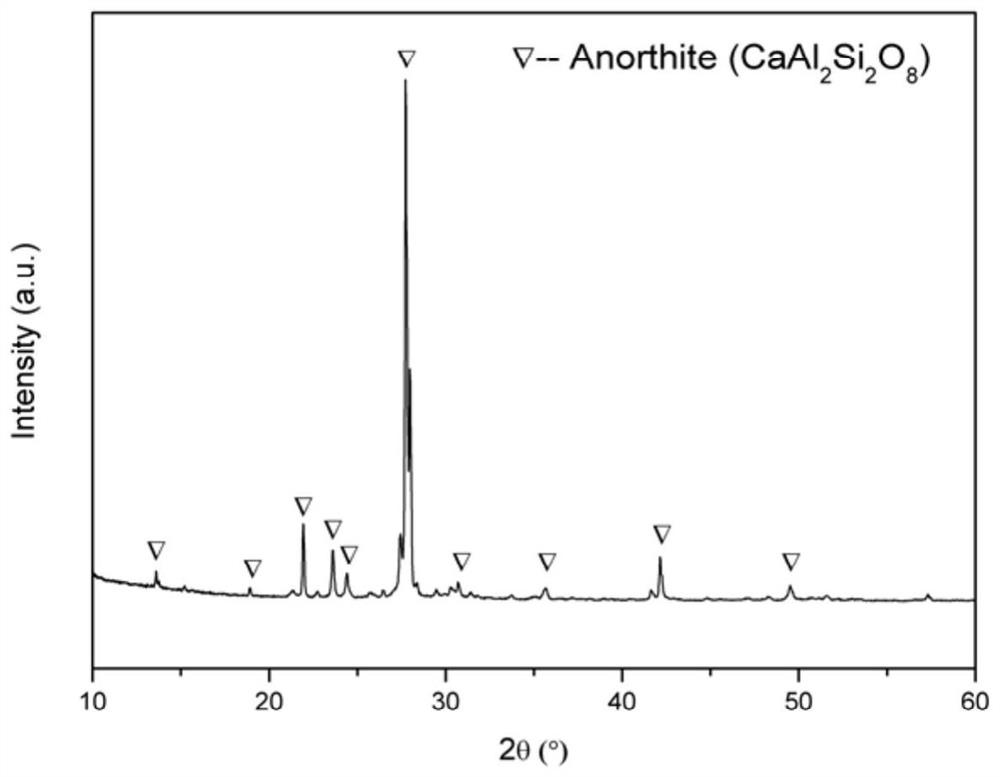

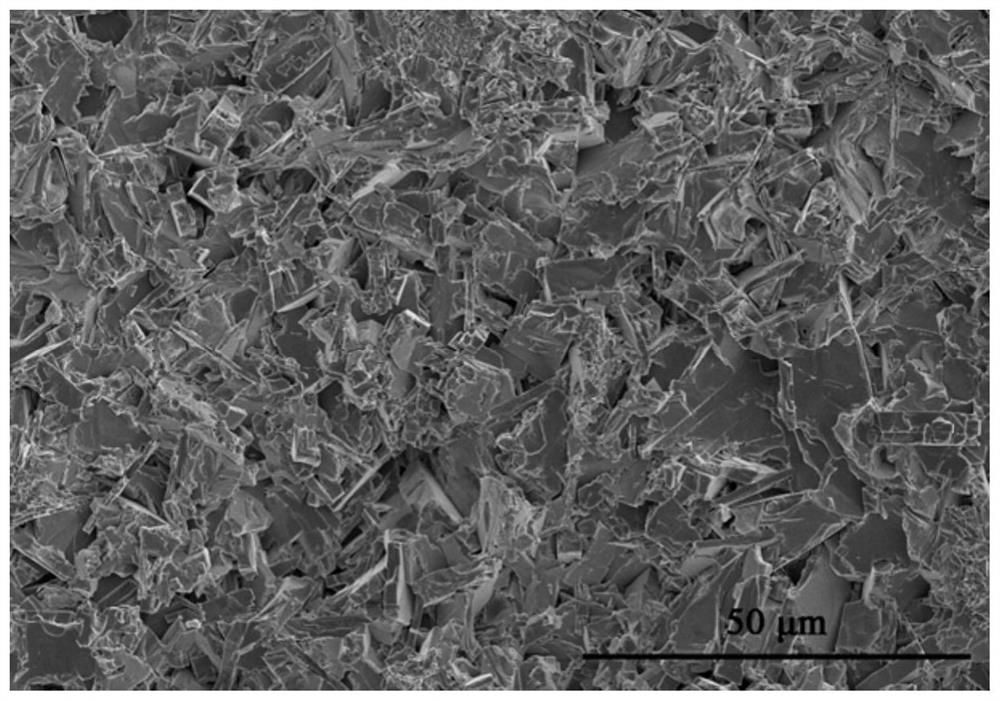

Image

Examples

Embodiment 1

[0022] 1. A non-zirconal calcium-free calcium-zirconal calcium-free glaze which has a raw material group being: 25 wt%, potassium longshine, 20 wt%, quartz 15Wt%, square solution 15 wt%, waterystone 5 wt %, Alumina 8 wt%, zinc oxide 3 wt%, burn talc 5 wt%, glass powder 10 wt%, nuclear agent 1 wt% (TiO 2 0.5 wt% + B 2 O 3 0.5 wt%). Among them, the raw material group of glass powder becomes SiO 2 65 wt%, Al 2 O 3 4 wt%, CAO 8WT%, MGO 3WT%, K 2 O 5WT%, NA 2 O 15 wt%.

[0023] 2. The preparation method of the above-free copium-free calcium long stone-based milk glaze, the steps are as follows:

[0024] (1) The ingredients are made according to the raw material of the above-mentioned emulsion glaze, and the water is hydrodynamic ball mill (according to the mass ratio material: the stone: water = 1: 2: 0.5) 8 h, the grain size D90 is 8.3 μm glaze;

[0025] (2) Adding water to adjust the specific gravity of the glaze pulverizer is 1.75g / cm 3 The flow rate is 25s / 100ml, and the glaz...

Embodiment 2

[0028] 1, the present embodiment has a zirconium calcium long stone-based milk glaze, its feedstock is: 8% by weight of clay, 30 wt%, quartz 15 wt%, square solution 20 wt%, alumina 8.5% by weight, zinc oxide 3 wt% 6Wt%, glass powder 9 wt%, nucleating agent P 2 O 5 0.5 wt%. Among them, the raw material group of glass powder becomes SiO 2 70 wt%, Al 2 O 3 3Wt%, CaO 8Wt%, MgO2WT%, K 2 O 4WT%, NA 2 O 13 wt%.

[0029] 2. The preparation method of the above-free copium-free calcium long stone-based milk glaze, the steps are as follows:

[0030] (1) The ingredients were made according to the raw material of the above emulsion glaze, and the water was hydrodynamic ball mill (according to the mass ratio material: water stone: water = 1: 2: 0.5) 6 h, gave a grain diameter D90 of 9.5 μm;

[0031] (2) Adding water to adjust the specific gravity of the glaze pulp is 1.50g / cm 3 The flow rate is 20s / 100ml, and the glaze paste is applied to the surface of the green manner;

[0032] (3) Burnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com