Sulfur wetting agent for wet chelated iron desulfurization and preparation and use method thereof

A wetting agent, chelated iron technology, applied in chemical instruments and methods, separation methods, disperse particle separation and other directions, can solve the problem of APEO product use restrictions and other problems, achieve low cost, wide source, good biodegradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

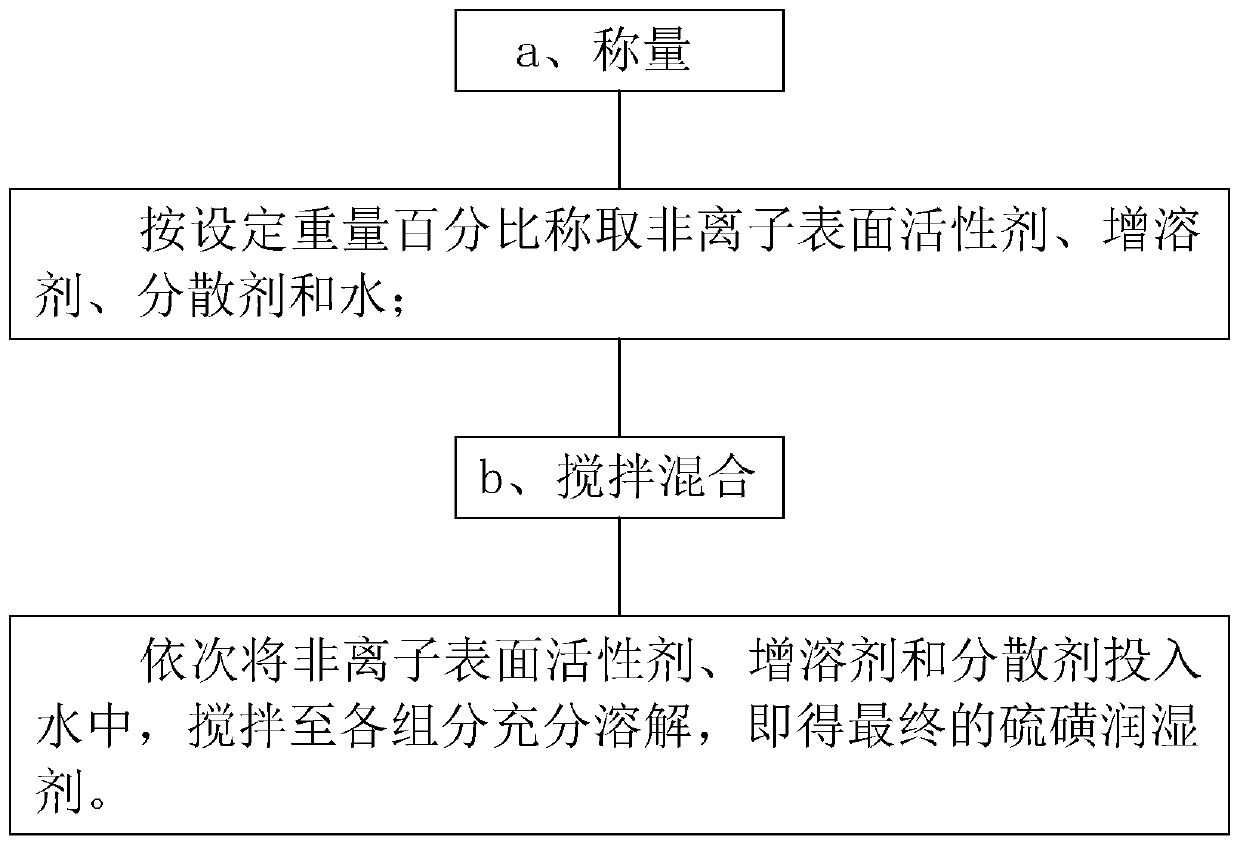

[0056] The preparation method of above-mentioned sulfur wetting agent, see figure 1 , including the following steps:

[0057] a. Weighing: weigh alkyl polyglucoside, cardanol polyoxyethylene ether (BGF-9), oleyl alcohol polyoxyethylene ether, ethanol and water according to the set weight percentage;

[0058] b. Stir and mix: Put alkyl polyglucoside, cardanol polyoxyethylene ether, oleyl alcohol polyoxyethylene ether, and ethanol into water in turn, stir until each component is fully dissolved and becomes transparent, and the final sulfur wetting agent is obtained .

Embodiment 2-4

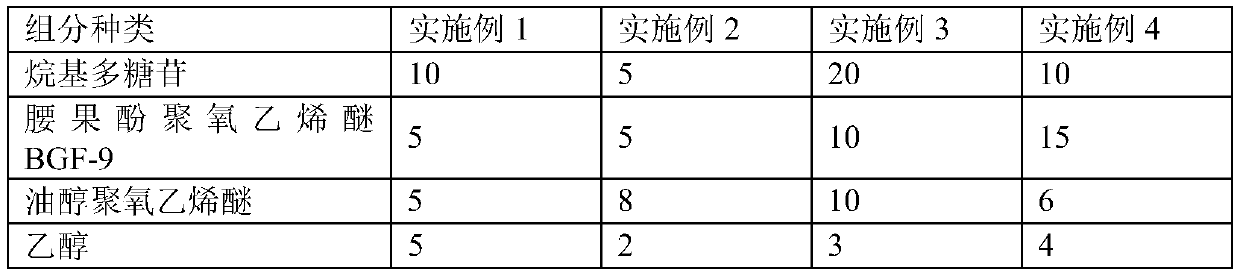

[0060] Examples 2-4 are all based on the method of Example 1, and the component content of the sulfur wetting agent is adjusted, and the specific adjustment is shown in Table 1 below.

[0061] The component table of table one embodiment 1-4

[0062]

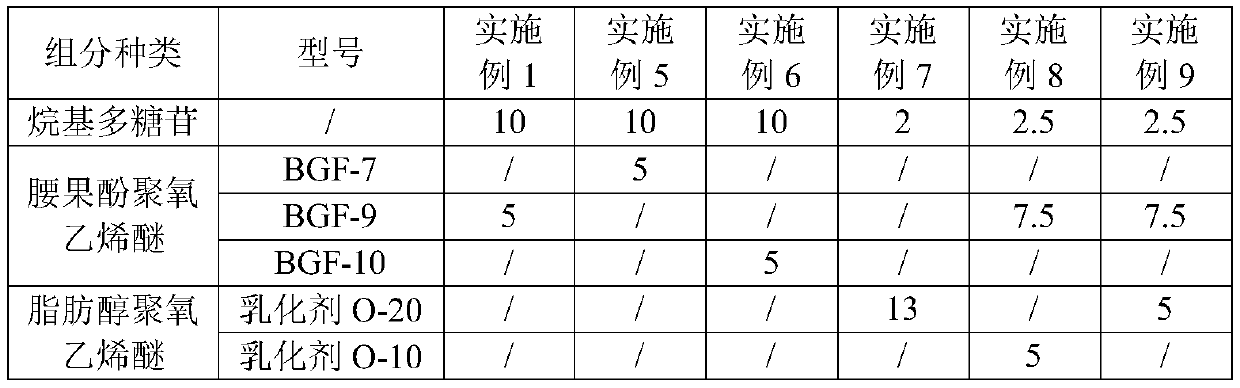

[0063] 2.3, Embodiment 5-9

[0064] Examples 5-9 are all based on the method of Example 1, and the components of the nonionic surfactant are adjusted, and the specific adjustments are shown in Table 2 below.

[0065] The nonionic surfactant component table of table two embodiment 1,5-9

[0066]

Embodiment 1

[0068] Examples 10-13 are all based on the method of Example 1, and the components of the dispersant are adjusted, and the specific adjustments are shown in Table 3 below.

[0069] The nonionic surfactant component table of table three embodiment 1,10-13

[0070] Component type Example 1 Example 10 Example 11 Example 12 Example 13 ethanol 5 / / / / propanol / 1.5 / 0.5 / Butanol / / 2 / / Isobutanol / / 1 1 / tert-butanol / / 1 / / 2-Methyl-2-butanol / / / 1.5 / Ethylene glycol / 3 / / / Propylene Glycol / / 1 / polyvinyl alcohol / / / / 5 N,N-Dimethylformamide / 0.5 / 2 /

[0071] 3. Comparative example

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com