A kind of environment-friendly anti-collapse drilling fluid and preparation method thereof

A drilling fluid and environmental protection technology, applied in the field of environmental protection anti-slump drilling fluid and its preparation, can solve the problems of not mentioning environmental protection performance, not providing temperature resistance data, etc. The effect of low filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] 1. Anti-slumping starch, prepared according to the preparation method of Example 3 in the Chinese patent application number 201811204630.5, specifically prepared by the method comprising the following steps:

[0054] (1) the cornstarch of 110g is dissolved in pure ethanol, is configured into weight concentration and is 22% cornstarch suspension, then 55g quaternary ammonium salt cationic agent 2,3-epoxypropyltrimethylammonium chloride and 9g alkaline catalyst sodium hydroxide is dissolved in the cornstarch suspension together, mixes evenly, obtains cornstarch slurry;

[0055] (2) 26g weight concentration is that more than 97% chloroacetic acid is dissolved in ethanol and is configured into the chloroacetic acid solution that weight concentration is 6%; 24g sodium hydroxide is dissolved in ethanol and is configured into the catalyst solution that weight concentration is 6%; Get step ( 1) Pour the prepared cornstarch slurry into a three-necked bottle, add 0.07g epichloroh...

Embodiment 1

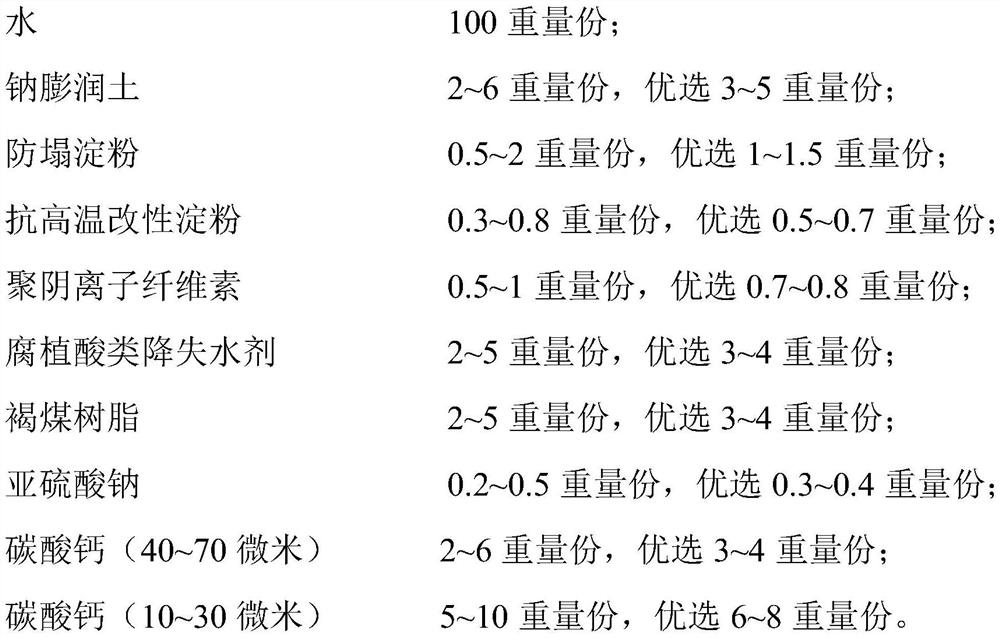

[0062] Preparation of environmentally friendly anti-slump drilling fluid:

[0063] Formula: Calculated based on the amount added to 500g of water, add 20g of sodium bentonite, stir well and then cure at room temperature for 24 hours. Add 5g anti-collapse starch, 2.5g high temperature resistant modified starch SMART, 3.5g PAC-LV, stir well to dissolve the polymer, then add 15g humic acid fluid loss reducer, 15g lignite resin, 1.5g Na 2 SO 3 , 15g of calcium carbonate (40-70 microns), and 30g of calcium carbonate (10-30 microns) were stirred evenly to obtain final product.

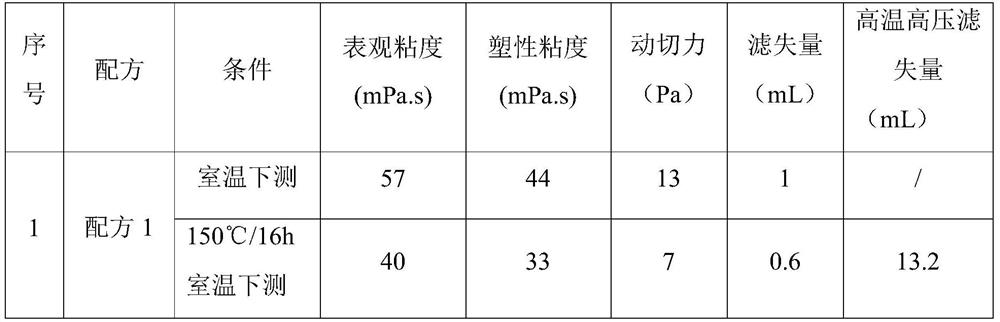

[0064] Performance Testing:

[0065] According to the method in GB / T 16783.1-2014 "Petroleum and Natural Gas Industry Drilling Fluid Field Test Part 1: Water-based Drilling Fluid", the apparent viscosity, plastic viscosity, dynamic shear force and neutral After pressure loss, it is sealed in an aging tank and rolled at 150°C for 16 hours. After cooling to room temperature, the apparent viscosity, plastic ...

Embodiment 2

[0070] Preparation of environmentally friendly anti-slump drilling fluid:

[0071] Formula: Calculated based on the amount added in 500g of water, take 3 parts of 500g of water each, add 15g, 20g, and 25g of sodium bentonite respectively, stir well and then cure at room temperature for 24 hours. Add 5g anti-collapse starch, 2.5gSMART, 3.5gPAC-LV and stir well to dissolve the polymer, then add 15g humic acid fluid loss reducer, 15g lignite resin, 1.5gNa 2 SO 3 , 15g of calcium carbonate (40-70 microns), and 30g of calcium carbonate (10-30 microns) were stirred evenly to make three parts of environmental protection anti-slump drilling fluid.

[0072] Performance Testing:

[0073] According to the method in GB / T 16783.1-2014 "Petroleum and Natural Gas Industry Drilling Fluid Field Test Part 1: Water-based Drilling Fluid", the apparent viscosity, plastic viscosity, dynamic shear force and Medium pressure dehydration, then sealed in aging tank at 150°C for 16 hours, cooled to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com