Super-hydrophilic anti-fog coating as well as preparation method and application thereof

An anti-fog coating, super-hydrophilic technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of titanium dioxide coating application limitations, etc., achieve good application prospects, long anti-fog time , highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Another aspect of the embodiments of the present invention also provides a method for preparing a super-hydrophilic anti-fog coating, which includes: at least using any one of the physical vapor deposition method, the sol-gel method, and the plasma-enhanced chemical vapor deposition method photocatalytically active TiO 2 Elemental doping is performed to deposit a super-hydrophilic anti-fog coating on the substrate.

[0029] Further, the doped elements include any one or a combination of metal elements and non-metal elements, and are not limited thereto.

[0030] Furthermore, the elements to be doped include any one or a combination of two or more of N, C, S, F, Fe, Cr, Ni, Cu, and are not limited thereto.

[0031] Further, the element doping includes single element doping or multi-element co-doping.

[0032] In some more specific embodiments, the method includes: placing the substrate in a vacuum chamber of a film coating equipment, and then sputtering a Ti target in ...

Embodiment 1

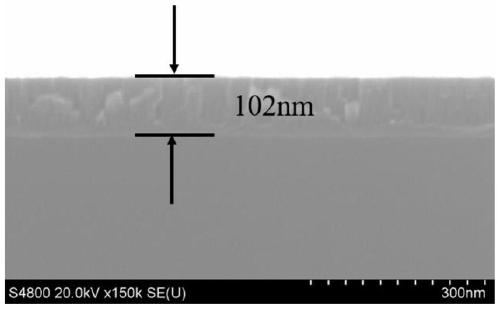

[0051] The N-doped TiO of this embodiment 2 A superhydrophilic anti-fog coating was prepared on a glass substrate by physical vapor deposition, and the N-doped TiO 2 The total thickness of the superhydrophilic anti-fog coating is about 100 nm.

[0052] The N-doped TiO 2 The superhydrophilic anti-fog coating can be prepared according to the following steps:

[0053] (1) Cleaning, degreasing, and surface activation treatment of the glass substrate: firstly, the glass substrate is cleaned and degreased with solvents such as ethanol and acetone, and then placed in the vacuum chamber of the reactive magnetron sputtering equipment, and the Vacuumize the vacuum chamber of the above-mentioned coating equipment, then raise the temperature in the vacuum chamber to 100°C, and pass in argon gas, turn on the ion beam, the ion beam voltage is 1300V, increase the gas ionization rate, and apply - 400V bias voltage to guide argon ions to bombard and activate the metal surface;

[0054] (2)...

Embodiment 2

[0057] The N-C co-doped TiO of the present embodiment 2 A superhydrophilic anti-fog coating was prepared on a glass substrate by physical vapor deposition, and the N-C co-doped TiO 2 The total thickness of the superhydrophilic anti-fog coating is about 150nm.

[0058] The N-C doped TiO 2 The superhydrophilic anti-fog coating can be prepared according to the following steps:

[0059] (1) Cleaning, degreasing, and surface activation treatment of the glass substrate: firstly, the glass substrate is cleaned and degreased with solvents such as ethanol and acetone, and then placed in the vacuum chamber of the reactive magnetron sputtering equipment, and the Vacuumize the vacuum chamber of the above-mentioned coating equipment, then raise the temperature in the vacuum chamber to 100°C, and pass in argon gas, turn on the ion beam, the ion beam voltage is 1300V, increase the gas ionization rate, and apply - 400V bias voltage to guide argon ions to bombard and activate the metal surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com