Organic-inorganic perovskite solar cell and preparation and recovery method thereof

A technology of solar cells and inorganic calcium, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as the inability to form thin films, reduce the energy conversion efficiency of metal-organic-inorganic perovskite solar cells, and the inability to eliminate complex preparation techniques, etc. , to achieve the effect of maintaining integrity, excellent photovoltaic efficiency and stability, and excellent photovoltaic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

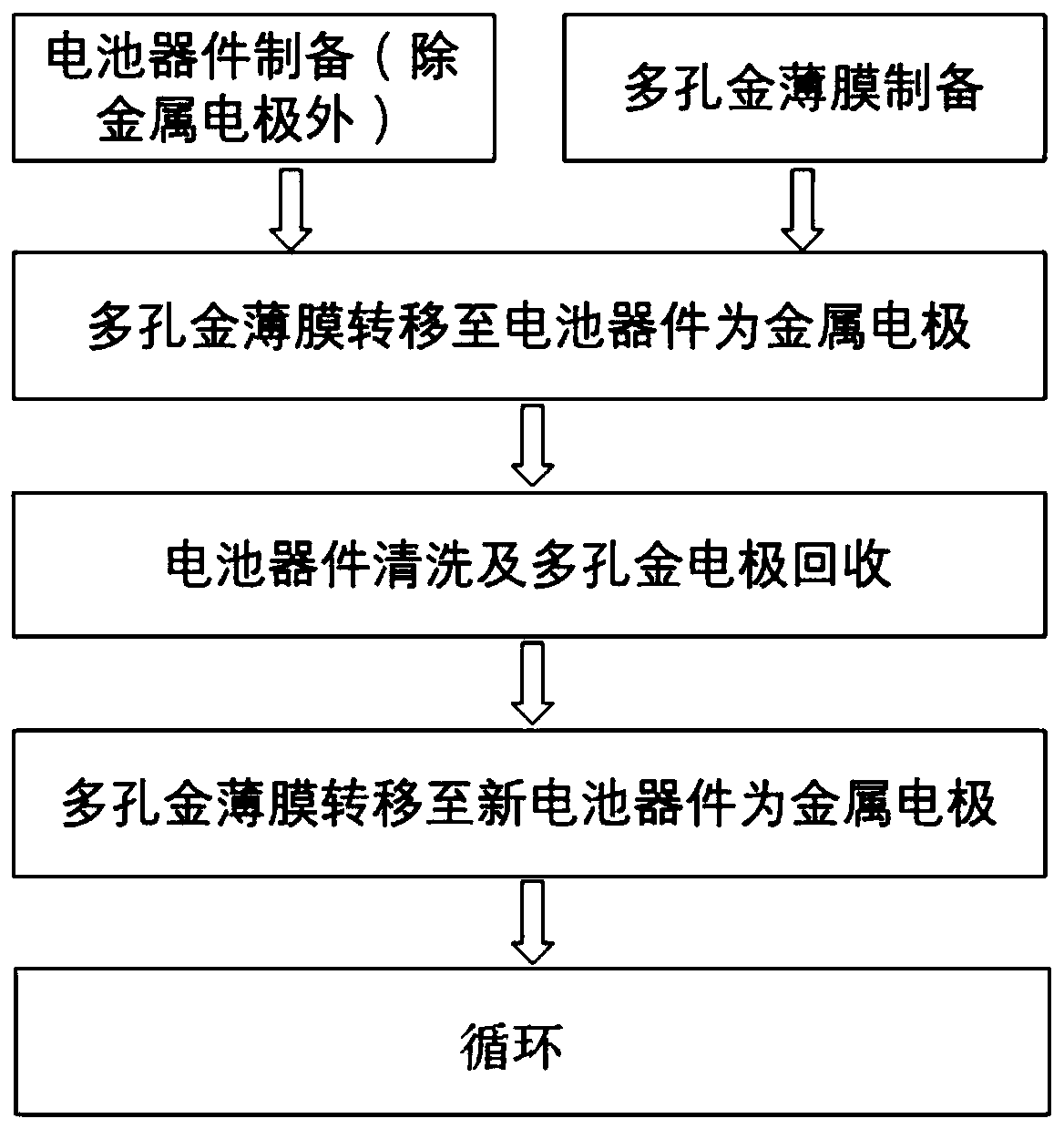

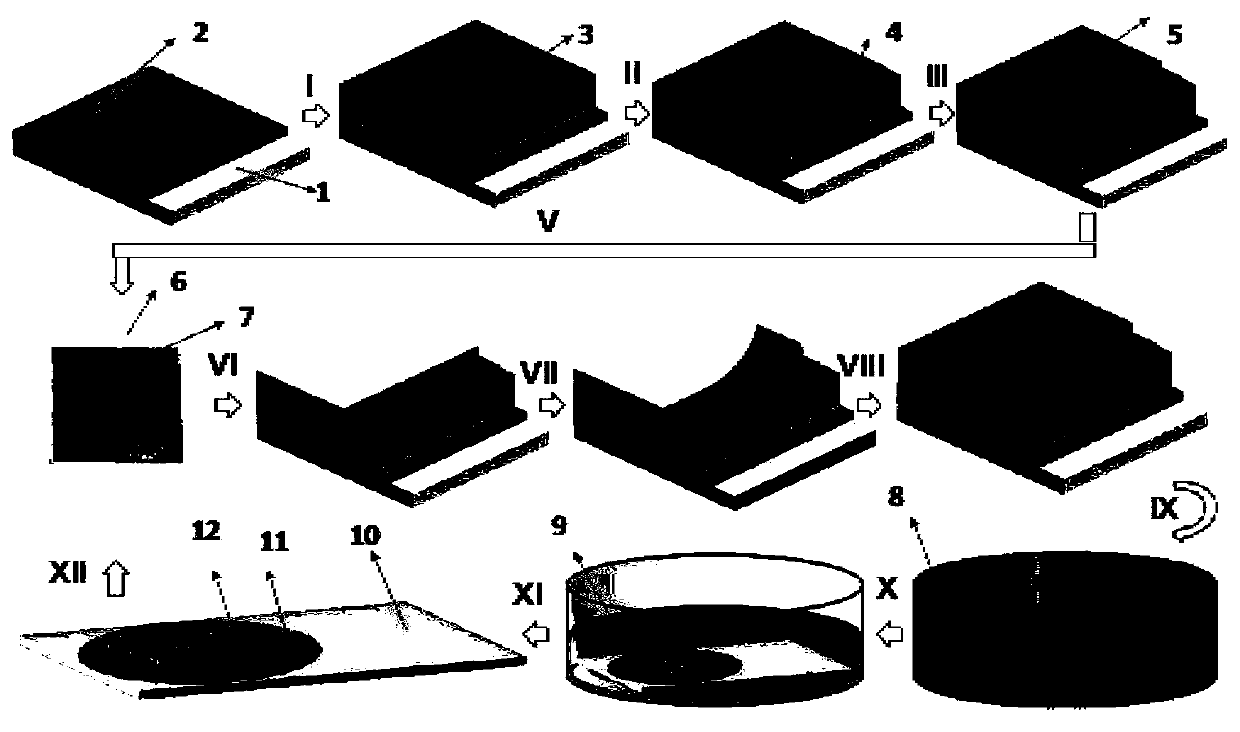

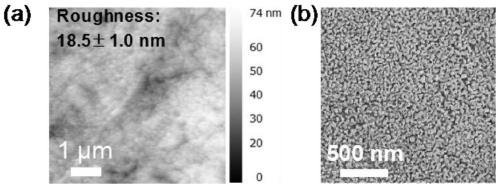

[0054] A preparation method of an organic-inorganic perovskite solar cell is carried out according to the following steps:

[0055] (1) ITO substrate preparation pretreatment

[0056] Spray the zinc oxide powder evenly on the surface of the ITO substrate 1, clean it with hydrochloric acid with a concentration of 6M, and then clean it with a detergent with a concentration of 1 wt% to remove oil stains, and then use acetone, isopropanol and deionized water for ultrasonic cleaning in sequence. Each sonication step was 10 min. Dry the cleaned ITO substrate 1 with an air gun and cut it into 25×25mm 2 The flakes are stored in a dry box, and the detergent is a commercially available conventional detergent;

[0057] (2) Electron transport layer preparation (I)

[0058] The ITO substrate 1 was treated with ozone for 15min, and then 15wt% of SnO 2 The nanoparticle aqueous solution plus deionized water is made into a 5wt% aqueous solution as a spin coating solution. Spin coating is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com