A kind of polyimide precursor composition and its preparation method and application

A polyimide precursor and composition technology, applied in the field of flexible materials, can solve the problems of low glass transition temperature, glass transition temperature of polyimide flexible substrate, heat resistance, dimensional stability and mechanical properties reduction, Reduce the film thickness of slurry and other problems, to meet the requirements of manufacturing process and subsequent use, improve the stability of molecular structure and molecular weight, and the effect of excellent heat resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

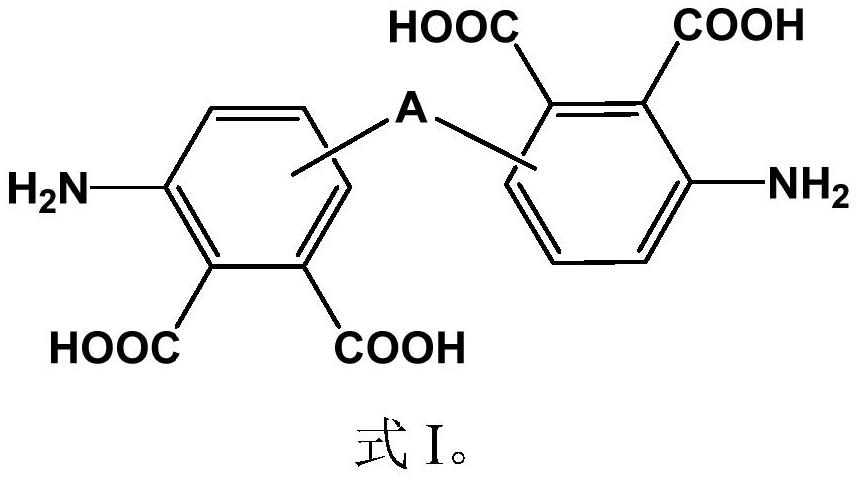

Method used

Image

Examples

Synthetic example 1

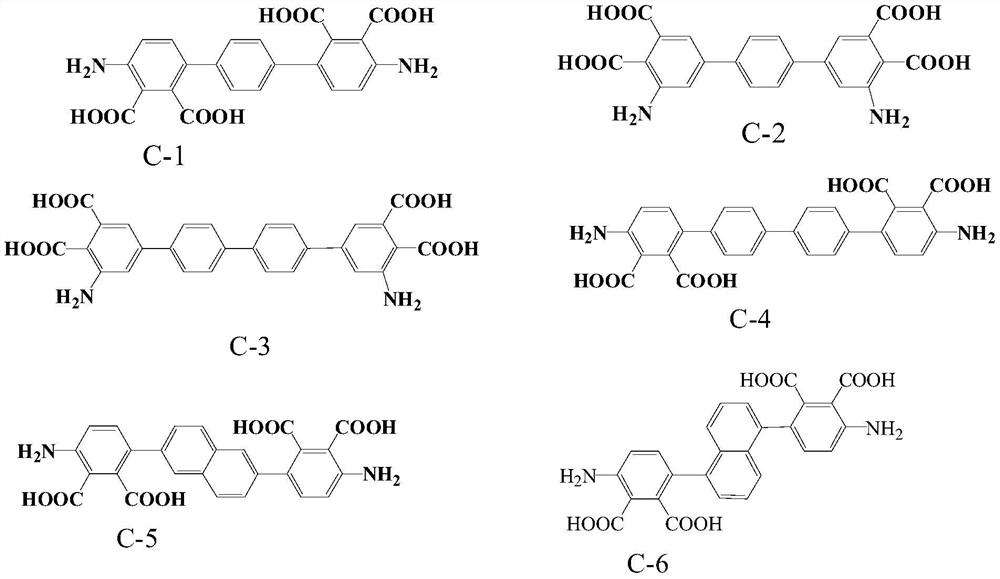

[0071] Preparation of compound C-1

[0072]

[0073] Step 1: Synthesis of Intermediate Compound A1

[0074] 34.5 g of 6-nitro-3-bromo-phthalic xylene and 6 g of NaOH were added to 550 mL of pyridine (py) and 280 mL of pure water, added and stirred, and the system was heated to reflux temperature. Subsequently, 118.5g potassium permanganate was slowly divided into multiple batches, the system was reacted at reflux temperature for 24h, manganese dioxide was filtered while hot, the filtrate was washed with hot water, concentrated, acidified with 2M hydrochloric acid solution, filtered and dried to obtain compound A1 31.3 g, yield 72%. Step 2: Synthesis of Intermediate Compound A2

[0075] 29.0g of 6-nitro-3-bromophthalic acid, 27.94g of pinacol biboronate, 49.1g of potassium acetate and 300mL of DMSO were sequentially added to the four-necked flask, and magnetic stirring was turned on. 7.3 g of 1,1'-bis(diphenylphosphino)ferrocene]dichloride palladium (Pd(dppf)Cl were subse...

Synthetic example 2

[0081] A diamine compound C-2, the structure is as follows:

[0082]

[0083] The difference between the preparation method and Synthesis Example 1 is that the compound 6-nitro-3-bromo-o-xylene in step (1) is used 6-nitro-4-bromo-o-xylene. Replacement; the target product C-2 was finally obtained, the yield was 3.55 g, and the yield was 21.5%.

[0084] The structural test data of the target product C-2 are as follows:

[0085] 1 H-NMR (400MHz, DMSO-d6), δ(ppm): 13.1(2H,s), 12.8(2H,s), 8.6(2H,d), 7.8(2H,d), 7.6(4H,s) , 5.9 (4H, s); elemental analysis (%): C (59.48), H (4.25), N (6.16).

Synthetic example 3

[0087] A diamine compound C-3, the structure is as follows:

[0088]

[0089] The difference between preparation method and synthesis example 1 is that the 6-nitro-3-bromo-o-xylene in step (1) is used 6-nitro-4-bromo-o-xylene. Replace the compound p-dibromobenzene in step (3) with 4,4'-dibromobiphenyl Substitution; the target product C-3 was finally obtained, 4.83 g, and the yield was 25.2%.

[0090] The structural test data of the target product C-3 are as follows:

[0091] 1 H-NMR (400MHz, DMSO-d6), δ(ppm): 13.1(2H,s), 12.8(2H,s), 8.6(2H,d), 7.8(2H,d), 7.6(8H,s) , 5.9 (4H, s); elemental analysis (%): C (64.85), H (4.05), N (5.35).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com