Aluminum-based porous coordination polymer and application thereof in adsorption of organic dyes in water

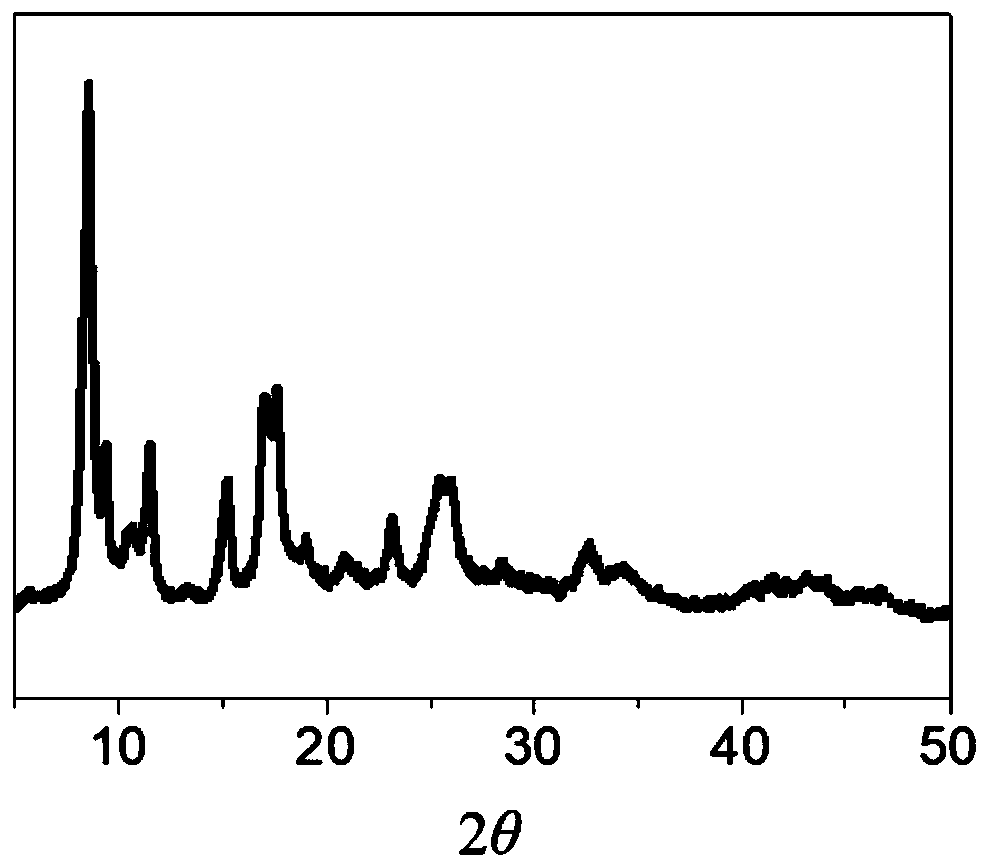

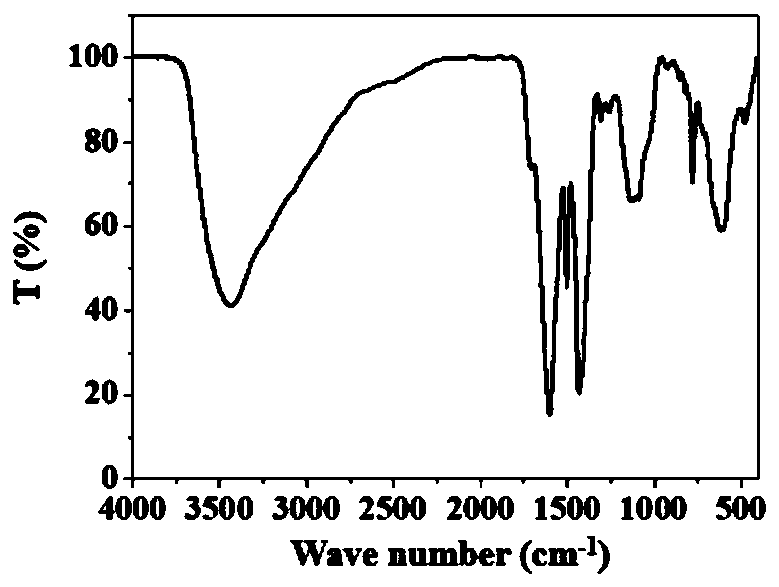

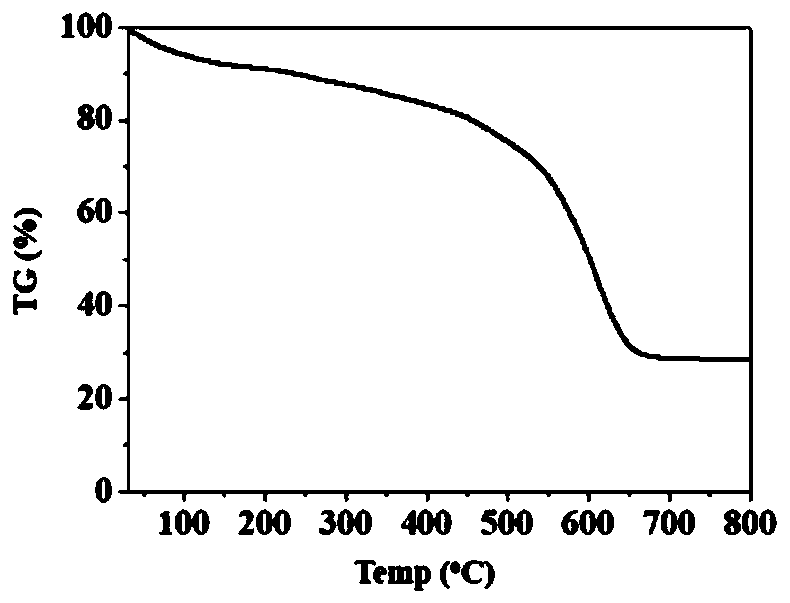

A coordination polymer and aluminum-based porous technology, which is applied in the direction of adsorption of water/sewage treatment, water pollutants, and other chemical processes, can solve the problems of low adsorption capacity, adsorption rate, lack of selectivity, and small specific surface. Achieve the effect of high adsorption capacity, fast adsorption rate and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An aluminum-based porous coordination polymer, the preparation method of which is as follows:

[0045] S1. Put 1.45g of aluminum chloride hexahydrate and 1.26g of 1,2,4-benzenetricarboxylic acid into the polytetrafluoroethylene lining of the hydrothermal reaction kettle, and then add 5mL of N,N-dimethylformaldehyde Amide (DMF) and 20mL of deionized water are mixed as a mixed solvent, and fully stirred to disperse to obtain a clear solution.

[0046] S2. Put the hydrothermal reaction kettle in an oven, react at 120°C for 12 hours, and then slowly lower to room temperature to obtain a white precipitate, which is collected by centrifugation, washed three times with DMF, and then washed three times with methanol. After the mother liquor was removed by centrifugation, the product was obtained by vacuum drying at 80°C with a yield of 65%.

Embodiment 2

[0048] An aluminum-based porous coordination polymer, the preparation method of which is as follows:

[0049] S1. Put 1.45g of aluminum chloride hexahydrate and 1.01g of 1,2,4-benzenetricarboxylic acid into the polytetrafluoroethylene lining of the hydrothermal reaction kettle, and then add 5mL of N,N-dimethylformaldehyde Amide (DMF) and 25mL of deionized water are mixed as a mixed solvent, and fully stirred to disperse to obtain a clear solution.

[0050] S2. Put the hydrothermal reaction kettle in an oven, react at 125°C for 10 hours, and then slowly lower to room temperature to obtain a white precipitate, which is collected by centrifugation, washed three times with DMF, and then washed three times with methanol. After the mother liquor was removed by centrifugation, the product was obtained by vacuum drying at 80°C.

Embodiment 3

[0052] An aluminum-based porous coordination polymer, the preparation method of which is as follows:

[0053] S1. Put 1.45g of aluminum chloride hexahydrate and 1.51g of 1,2,4-benzenetricarboxylic acid into the polytetrafluoroethylene lining of the hydrothermal reaction kettle, and then add 5mL of N,N-dimethylformaldehyde Amide (DMF) and 15mL of deionized water are mixed as a mixed solvent, and fully stirred to disperse to obtain a clear solution.

[0054] S2. Put the hydrothermal reaction kettle in an oven, react at 115°C for 15 hours, and then slowly lower to room temperature to obtain a white precipitate, which is collected by centrifugation, washed three times with DMF, and then washed three times with methanol. After the mother liquor was removed by centrifugation, the product was obtained by vacuum drying at 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com