A kind of low-melt viscosity high-pressure waterproof moisture-curing hot-melt adhesive and preparation method thereof

A moisture-curing, low-melt-viscosity technology, applied in adhesive types, adhesives, polyurea/polyurethane adhesives, etc., can solve problems such as high melt viscosity, achieve high bonding strength, overcome internal stress, reduce The effect of crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

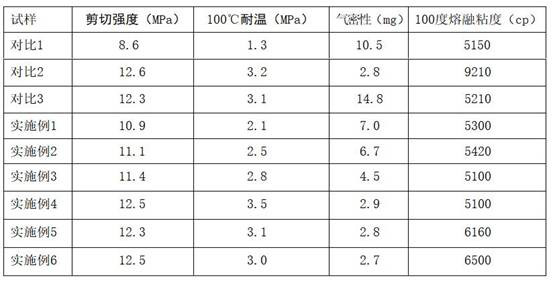

Examples

example 1

[0049]Mix 40g of self-made low molecular weight polyester polyol (average molecular weight at 3000, hydroxyl value (mgKOH / g): 81.2) and 25g of polycaprolactone diol (average molecular weight at 2000, hydroxyl value (mgKOH / g): 56.1) The mixture, 15g of terpene resin was added to the reaction kettle and mixed and stirred at a stirring speed of 300rpm, the temperature was raised to 100-120 ℃, and the stirring was continued; when the mixture in the kettle was homogeneous, the vacuum pump was turned on, and the vacuum was evacuated, and the pressure was controlled at 0.01-0.098 MPa dehydration for two hours; after cooling down to 85-90 °C, add 15 g of diphenylmethane diisocyanate and 0.5 g of dibutyltin dilaurate into the reaction kettle, turn on the vacuum and keep stirring at 85-90 °C for 80 minutes, Stirring speed 150rpm; add 1.5g 1.4-butanediol, vacuumize and stir at 85-90°C for 120 minutes, stirring speed 150rpm; finally add 1g carbonized PMMA filler and 0.5g 4,4'-(oxydi-2, 1-...

example 2

[0051] Mix 45g of self-made low molecular weight polyester polyol (average molecular weight at 3000, hydroxyl value (mgKOH / g): 81.2) and 20g of polycaprolactone diol (average molecular weight at 2000, hydroxyl value (mgKOH / g): 56.1) The mixture, 15g of terpene resin was added to the reaction kettle and mixed and stirred at a stirring speed of 300rpm, the temperature was raised to 100-120 ℃, and the stirring was continued; when the mixture in the kettle was homogeneous, the vacuum pump was turned on, and the vacuum was evacuated, and the pressure was controlled at 0.01-0.098 MPa dehydration for two hours; after cooling down to 85-90°C, add 15 g diphenylmethane diisocyanate and 0.5 g dibutyltin dilaurate into the reaction kettle, turn on the vacuum and keep stirring at 85-90°C for 80 minutes, Stirring speed 150rpm; add 1.5g 1.4-butanediol, vacuumize and stir at 85-90°C for 120 minutes, stirring speed 150rpm; finally add 2g carbonized PMMA filler and 0.5g 4,4'-(oxydi-2, 1-ethaned...

example 3

[0053] Mix 50g of self-made low molecular weight polyester polyol (average molecular weight at 3000, hydroxyl value (mgKOH / g): 81.2) and 15g of polycaprolactone diol (average molecular weight at 2000, hydroxyl value (mgKOH / g): 56.1) The mixture, 15g of terpene resin was added to the reaction kettle and mixed and stirred at a stirring speed of 300rpm, the temperature was raised to 100-120°C, and the stirring was continued; when the kettle was mixed

[0054] After the material is homogeneous, turn on the vacuum pump, evacuate, and control the pressure at 0.01-0.098MPa for dehydration for two hours; after cooling down to 85-90°C, add 15 g of diphenylmethane diisocyanate and 0.5 g of dibutyltin dilaurate to the reaction In the kettle, turn on the vacuum and keep stirring at 85-90°C for 80 minutes at a stirring speed of 150rpm; add 1.5g of 1.4-butanediol, vacuumize and stir at 85-90°C for 120 minutes at a stirring speed of 150rpm; finally add 3g of carbonized PMMA filler and 0.5g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com