Preparation method and application of sludge-based gas diffusion particle electrode

A particle electrode and gas diffusion technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., to achieve stable effects, alleviate deactivation, and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

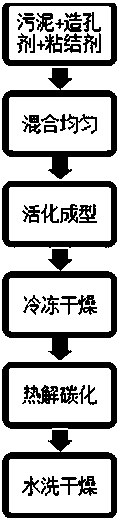

[0026] See attached figure 1 , according to the following steps to prepare the sludge-based gas diffusion particle electrode:

[0027] 1. Mechanical dewatering of sludge

[0028] The mechanically dehydrated sludge was dried at a temperature of 105° C. to a moisture content of 5 wt%, and the dried sludge was pulverized by a pulverizer and sieved with 200 meshes to obtain sludge powder.

[0029] 2. Activation of sludge

[0030] Add 2% sodium carboxymethyl cellulose as binder and 15% polymethyl methacrylate as pore-forming agent to the sludge powder, stir and add sludge 30% by mass of 5 mol / L zinc chloride solution, activated for 18 h.

[0031] 3. Forming of raw sludge ring

[0032] Stir the activated sludge, knead it into a ball, weigh 6 g of sludge and place it in a silica gel mold, freeze at -20°C for 20 minutes, take out the molded sludge ring, and freeze-dry it after the outer diameter is stabilized to 2.0 cm 15h is the sludge raw material ring.

[0033] 4. Pyrolytic c...

Embodiment 2

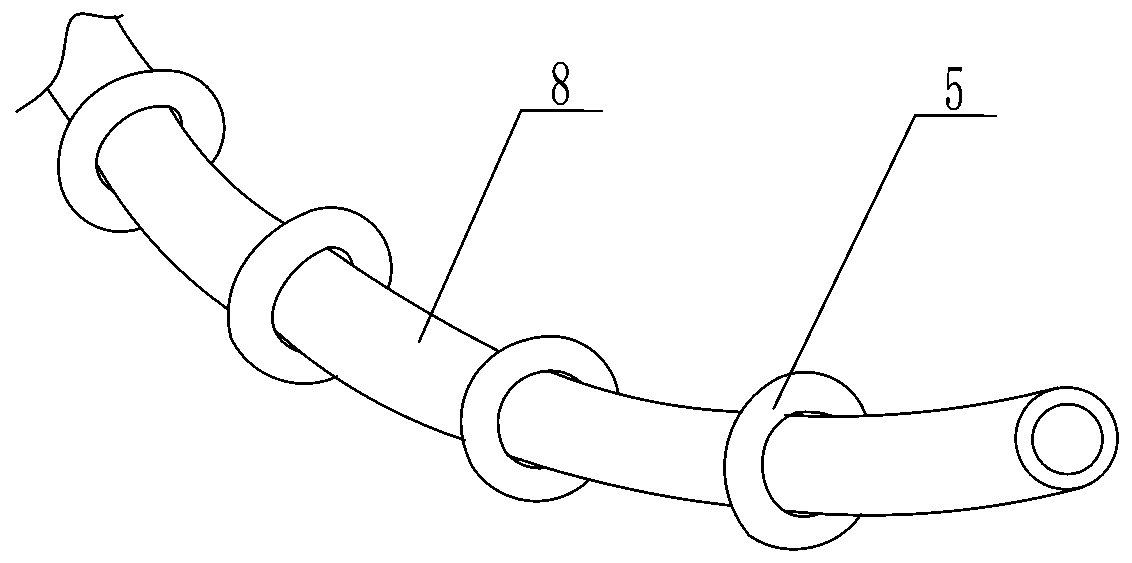

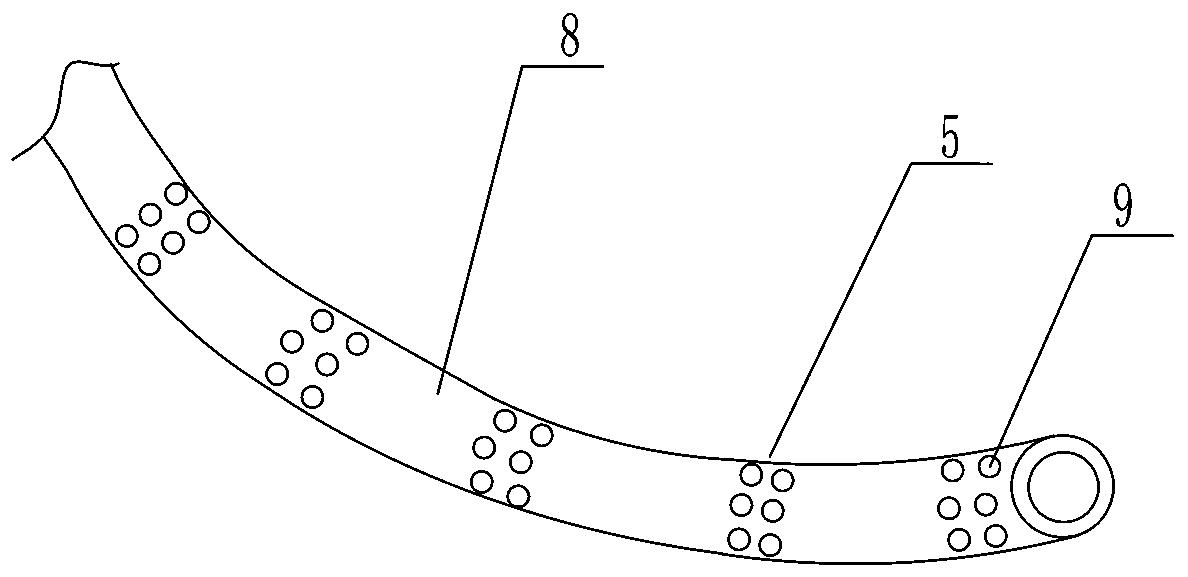

[0038] See attached figure 2 , the carbonized sludge ring 5 prepared in Example 1 was used as sludge-based gas diffusion particle electrodes, and arranged in series on the plastic hose 8 to prepare electrode series with a spacing of 2.5 cm.

[0039] See attached image 3 , the place where the plastic hose 8 is connected to the carbonized sludge ring 5 is provided with several air outlet holes 9 .

[0040] refer to Figure 4 , the particle electrodes with a total mass of 36.8 g were vertically placed in a three-dimensional electrochemical reactor, connected by branch pipes to form two rows, one row of four strings, and each string had four carbonized sludge rings 5 (particle electrodes), and the electrode strings were filled in A catalyst is used between the anode 2 and the cathode 3 connected to the DC stabilized voltage power supply 1 to perform electrocatalytic oxidation treatment on the rhodamine B dye wastewater 6 . The anode 2 of the three-dimensional electrochemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com