Electroplated coating silk-screen printing ink and preparation method thereof

A screen printing ink and electroplating coating technology, applied in ink, household utensils, applications, etc., can solve the problem of being unable to resist strong acid and strong corrosion, and screen printing ink cannot meet high strength, high adhesion, acid resistance, corrosion resistance, and water resistance at the same time Cooking and other problems, to achieve the effect of improving adhesion, improving smoothness, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

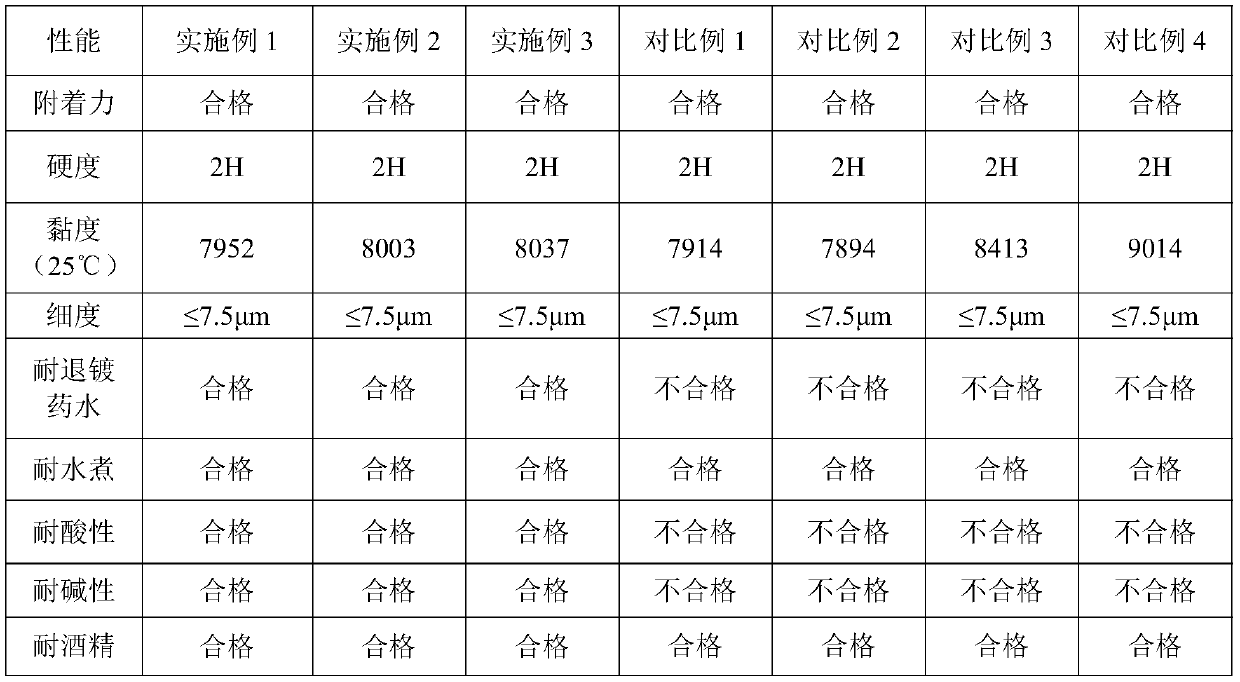

Examples

Embodiment 1

[0031] An electroplating coating screen printing ink, which comprises the following components: epoxy acrylate prepolymer 20Kg; dehydration ricinoleic acid modified epoxy resin 20Kg; isocyanate curing agent 3.5Kg; functional filler (nano silicon dioxide) 0.3Kg ; Functional filler (nano alumina) 0.5Kg; Talc powder 1.5Kg; Carbon black 3.2Kg; Dispersant 0.9Kg; Defoamer (BYK 054) 0.2Kg; Ketone) 2Kg; Solvent (isophorone) 5Kg; Solvent (trimethylbenzene) 8Kg; Solvent (dibasic acid ester) 7Kg.

[0032] The preparation method of above-mentioned epoxy acrylate prepolymer is as follows: Epoxy resin (E44) 40Kg, tetraethylammonium bromide 0.4Kg, p-hydroxyanisole 0.008Kg and acrylic acid 10Kg carry out chemical reaction at 90 ℃, to be reacted When the acid value of the system is less than 3mgKOH / g, just cool down and discharge.

[0033] The preparation method of the above-mentioned dehydrated ricinoleic acid modified epoxy resin is as follows: After mixing 1Kg of epoxy resin (E44) and 20Kg...

Embodiment 2

[0036]A kind of electroplating coating screen printing ink, it comprises following components: epoxy acrylate prepolymer 22.5Kg; Dehydration ricinoleic acid modified epoxy resin 22.5Kg; Isocyanate curing agent 5.5Kg; Functional filler (nano silicon dioxide) 0.8Kg; functional filler (nano alumina) 0.6Kg; talc powder 2.4Kg; carbon black 4.5Kg; dispersant 1.5Kg; defoamer (BYK 054) 0.5Kg; leveling agent (BYK 307) 0.5Kg; Cyclohexanone) 4Kg; Solvent (isophorone) 8Kg; Solvent (trimethylbenzene) 5Kg; Solvent (dibasic acid ester) 9Kg.

[0037] The preparation method of above-mentioned epoxy acrylate prepolymer is as follows: Epoxy resin (E44) 50Kg, tetraethylammonium bromide 0.5Kg, p-hydroxyanisole 0.01Kg and acrylic acid 12Kg carry out chemical reaction at 95 ℃, to be reacted When the acid value of the system is less than 4mgKOH / g, just cool down and discharge.

[0038] The preparation method of the above-mentioned dehydrated ricinoleic acid modified epoxy resin is as follows: After ...

Embodiment 3

[0041] A kind of electroplating coating screen printing ink, it comprises following components: epoxy acrylate prepolymer 25Kg; Dehydration ricinoleic acid modified epoxy resin 25Kg; Isocyanate curing agent 8.5Kg; Functional filler (nano silicon dioxide) 0.6Kg ; Functional filler (nano alumina) 0.9Kg; Talc powder 2.8Kg; Carbon black 6.5Kg; Dispersant 2.5Kg; Defoamer (BYK 054) 0.8Kg; Ketone) 7Kg; Solvent (isophorone) 12Kg; Solvent (trimethylbenzene) 10Kg; Solvent (dibasic acid ester) 7Kg.

[0042] The preparation method of above-mentioned epoxy acrylate prepolymer is as follows: Epoxy resin (E44) 60Kg, tetraethylammonium bromide 0.6Kg, p-hydroxyanisole 0.012Kg and acrylic acid 15Kg carry out chemical reaction at 100 ℃, to be reacted When the acid value of the system is less than 4mg KOH / g, cool down and discharge.

[0043] The preparation method of the above-mentioned dehydrated ricinoleic acid modified epoxy resin is as follows: After mixing 1Kg of epoxy resin (E44) and 20Kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com