Wetting dispersant and pendimethalin suspending agent using wetting dispersant

A wetting and dispersing agent, pendimethalin technology, applied in herbicides and algicides, chemicals for biological control, applications, etc., can solve problems such as sanding difficulties, creaming, and material thickening. Achieve good surface activity, improve stability and reduce tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

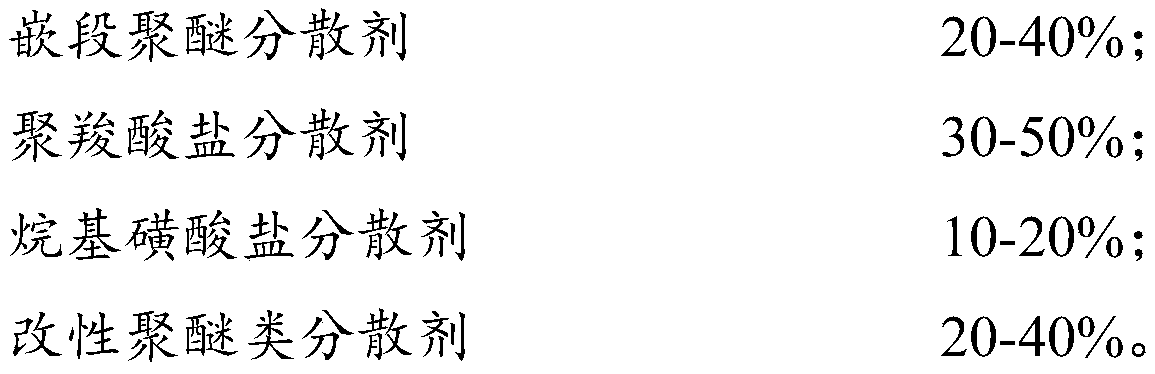

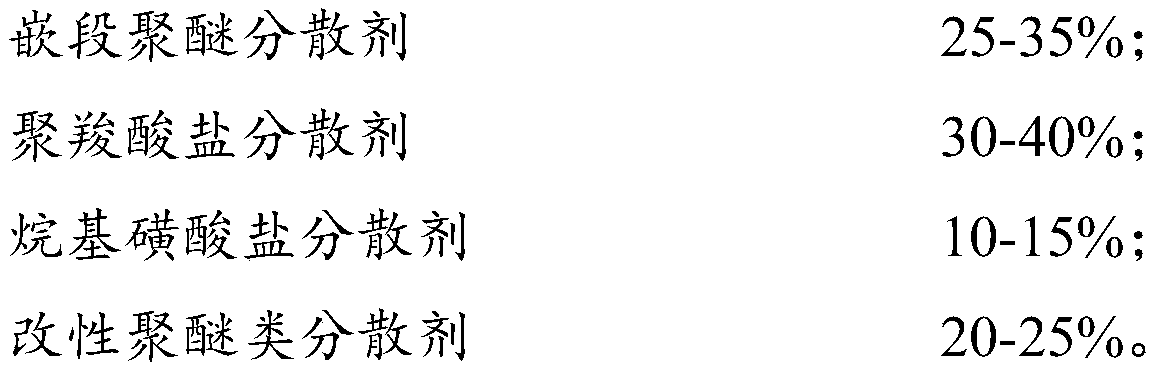

[0031] A wetting and dispersing agent, composed of the following components in mass percentage: 35% of hydroxyl polyethylene oxide block copolymer, 30% of polyacrylic acid sodium salt, 15% of tristyrylphenol sulfonate, alkylphenol modified 20% polyoxyethylene ether mixed evenly.

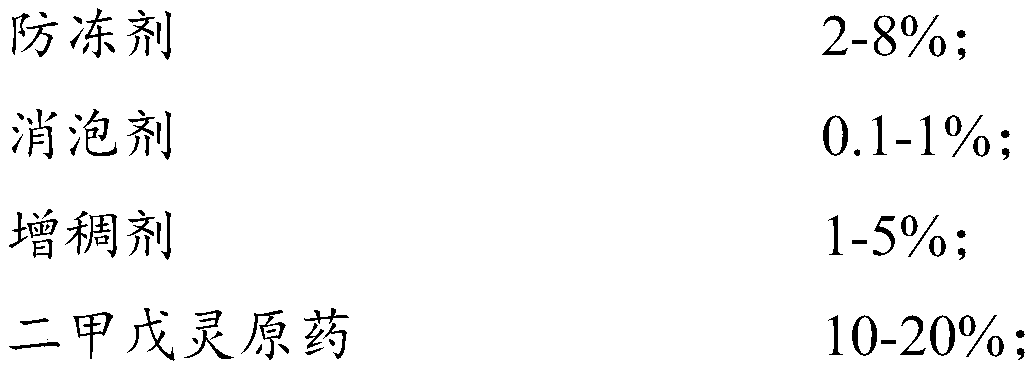

[0032] Adopt this mixed auxiliary agent to process 20% pendimethalin suspending agent, concrete method is: take by weighing 10g mixed wetting and dispersing agent and place in the sample cup of sand mill, add 62.8g tap water, 5g ethylene glycol, 0.2g of defoamer and 2g of xanthan gum were mixed uniformly to form an aqueous solution, and then 2g of white carbon black and 20g of pendimethalin were added and mixed uniformly to form a slurry to be ground. 120 g of zirconia beads were added to the slurry to be ground, and placed on a sand mill for grinding at a speed of 1600 rpm for 1 hour. After 1 hour, the ground slurry was collected to be a 20% pendimethalin suspension concentrate sample.

Embodiment 2

[0034] A wetting and dispersing agent, consisting of the following mass percentage components: 25% fatty alcohol ethylene oxide propylene oxide block copolymer, 40% polyacrylic acid ammonium salt, 10% dodecylbenzenesulfonate, fatty acid Modified polyoxyethylene ether 25% mixed uniformly.

[0035] Adopt this mixed auxiliary agent to process 10% pendimethalin suspending agent, concrete method is: take by weighing 10g mixed wetting and dispersing agent and place in the sample cup of sand mill, add 72.9g tap water, 2g ethylene glycol, 0.1 g of defoaming agent and 2 g of xanthan gum were mixed uniformly to form an aqueous solution, and then 5 g of white carbon black and 10 g of pendimethalin original drug were added and mixed uniformly to form a slurry to be ground. 120 g of zirconia beads were added to the slurry to be ground, and placed on a sand mill for grinding at a speed of 1600 rpm for 1 hour. After 1 hour, the ground slurry was collected to be a 10% pendimethalin suspensio...

Embodiment 3

[0037] A wetting and dispersing agent, consisting of the following components in mass percentage: 30% propylene glycol block polyether, 35% polyacrylic acid sodium salt, 12% alkenyl sulfonate, 23% castor oil modified polyoxyethylene ether and mix well made.

[0038] Adopt this mixed auxiliary agent to process 15% pendimethalin suspending agent, concrete method is: take by weighing 15g mixed wetting and dispersing agent and place in the sample cup of sand mill, add 67.8g tap water, 5g ethylene glycol, Mix 0.2g of defoamer and 2g of xanthan gum to form an aqueous solution, then add 2g of white carbon black and 10g of pendimethalin and mix evenly to form a slurry to be ground. 120 g of zirconia beads were added to the slurry to be ground, and placed on a sand mill for grinding at a speed of 1600 rpm for 1 hour. After 1 hour, the ground slurry was collected to be a 15% pendimethalin suspension concentrate sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com