Ammonium ferrous phosphate as well as preparation method and application thereof

A technology of ammonium ferrous phosphate and ferrous pyrophosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high raw material requirements, difficult doping, and low batch stability of lithium iron phosphate. , to achieve the effect of scientific preparation method, low roasting temperature, uniformity of doping and related performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment discloses a ferrous ammonium phosphate whose general formula is NH 4 FePO 4 .

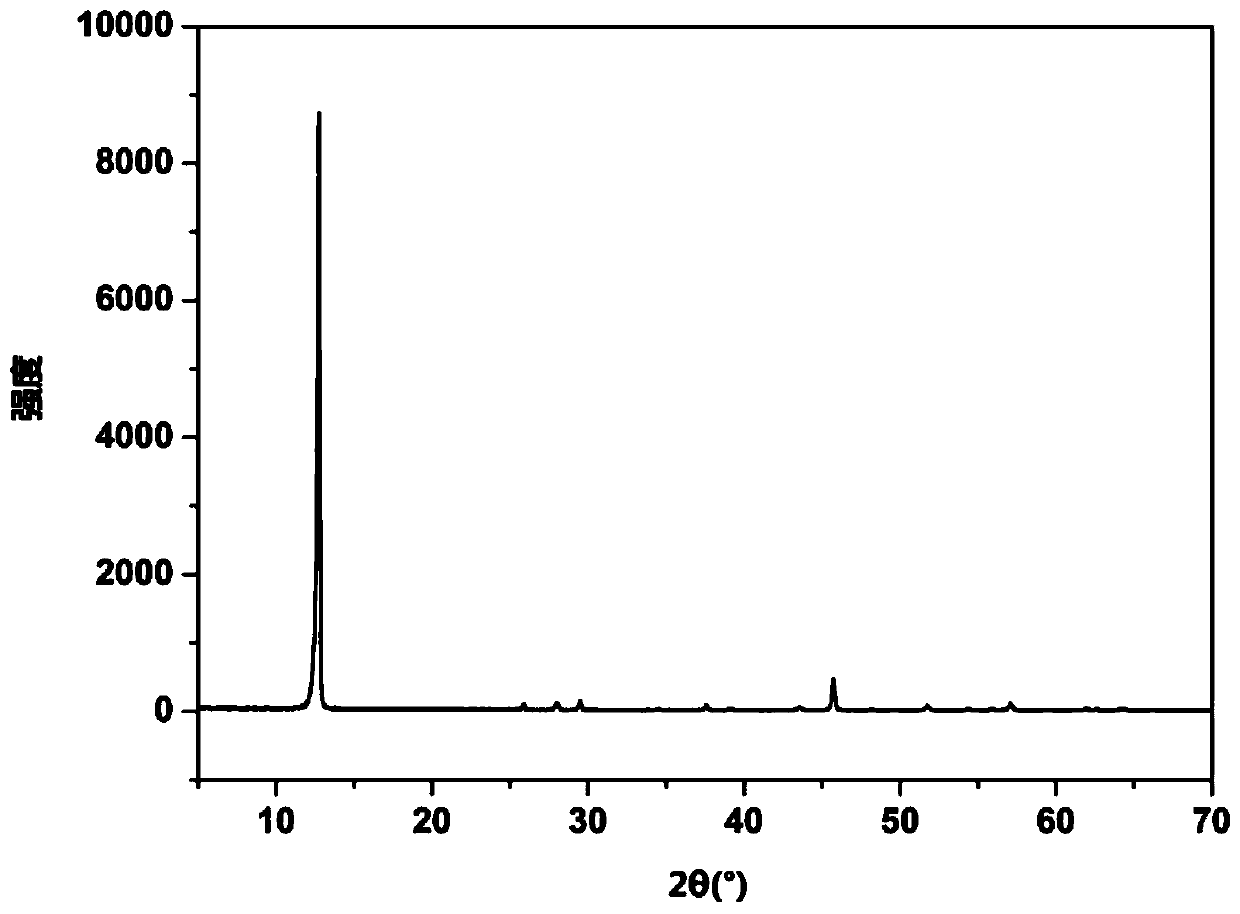

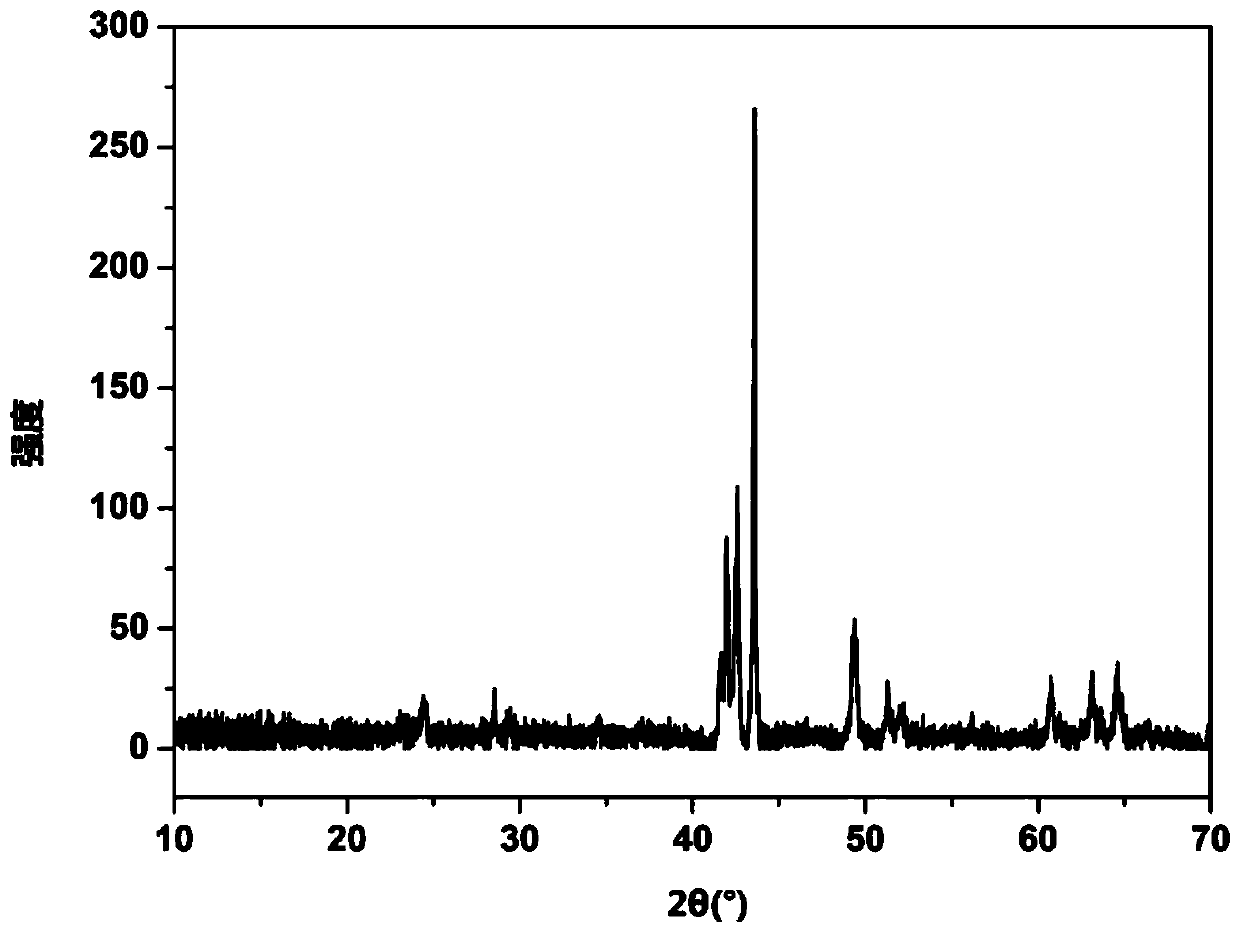

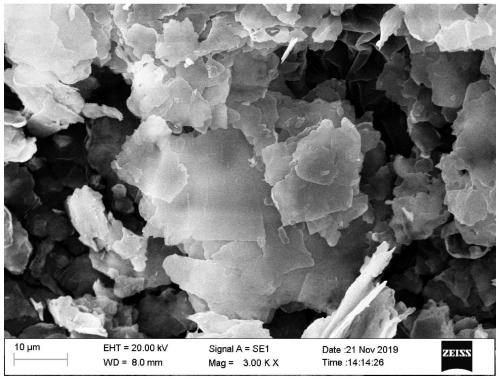

[0051] The preparation method of ferrous ammonium phosphate comprises the following steps: take by weighing 27.8g ferrous sulfate heptahydrate and 11.54g concentrated phosphoric acid (85%) and be dissolved in 200mL secondary water, be placed in 70 ℃ of water baths and stir 30min, stir to Dissolve, pass argon gas for atmosphere protection, prevent ferrous iron from being oxidized by air, use a peristaltic pump to add concentrated ammonia water to the reaction system dropwise, adjust the reaction pH=7, maintain the reaction system pH and continue the reaction for 10 minutes, filter and wash the precipitate 3 times After drying, obtain ferrous ammonium phosphate. Such as figure 1 As shown, the obtained XRD spectrum of ammonium ferrous phosphate is compared with the standard spectrum in the spectral library, and it is determined that the compound obtained is ferrous ammonium p...

Embodiment 2

[0058] This embodiment discloses a ferrous ammonium phosphate whose general formula is NH 4 FePO 4 .

[0059] The preparation method of ferrous ammonium phosphate comprises the following steps: take by weighing 27.8g ferrous sulfate heptahydrate and 11.54g concentrated phosphoric acid (85%) and be dissolved in 200mL secondary water, be placed in 90 ℃ of water baths and stir 10min, stir to Dissolve, pass argon gas for atmosphere protection, prevent ferrous iron from being oxidized by air, use a peristaltic pump to drop concentrated ammonia water into the reaction system, adjust the reaction pH=6, maintain the reaction system pH and continue the reaction for 30 minutes, filter and wash the precipitate 3 times After drying, obtain ferrous ammonium phosphate.

[0060] The method for preparing lithium iron phosphate by using the above-mentioned ferrous ammonium phosphate comprises the following steps:

[0061] Place the dried ammonium ferrous phosphate in a tube furnace and roas...

Embodiment 3

[0066] This embodiment discloses a ferrous ammonium phosphate whose general formula is NH 4 Fe 0.8 V 0.2 PO 4 .

[0067] The preparation method of ammonium ferrous phosphate comprises the following steps: take by weighing 0.5g vanadyl sulfate, 27.8g ferrous sulfate heptahydrate and 11.54g concentrated phosphoric acid (85%) and dissolve in 200mL secondary water, place it in a 90°C water bath Stir in the medium for 10 minutes, stir until dissolved, pass argon for atmosphere protection, prevent iron and vanadium from being oxidized by air, use a peristaltic pump to drop concentrated ammonia water into the reaction system, adjust the reaction pH=7, maintain the reaction system pH and continue the reaction for 60 minutes. The precipitate was filtered and washed three times and then dried to obtain vanadium-doped ferrous ammonium phosphate.

[0068] The method for preparing lithium iron phosphate by using the above-mentioned ferrous ammonium phosphate comprises the following ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com