Preparation method of rare earth fluoride

A technology of rare earth fluoride and ammonium fluoride, applied in the direction of rare earth metal halides, rare earth metal fluorides, etc., can solve the problems of fast consumption, high cost of materials resistant to hydrogen fluoride gas, and high price of hydrogen fluoride gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a preparation method of rare earth fluoride, comprising the following steps:

[0018] After mixing the rare earth carbonate and ammonium fluoride, the fluorination reaction is carried out, and then raising the temperature to remove the remaining ammonium fluoride to obtain the rare earth fluoride; the molar ratio of the rare earth carbonate to the ammonium fluoride is 1:6-18.

[0019] In the present invention, unless otherwise specified, the preparation raw materials used in the present invention are commercially available products well known in the art.

[0020] The invention mixes the rare earth carbonate and ammonium fluoride to obtain the mixed material. In the present invention, the rare earth elements contained in the rare earth carbonate are preferably lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, yttrium and scandium. at least one...

Embodiment 1

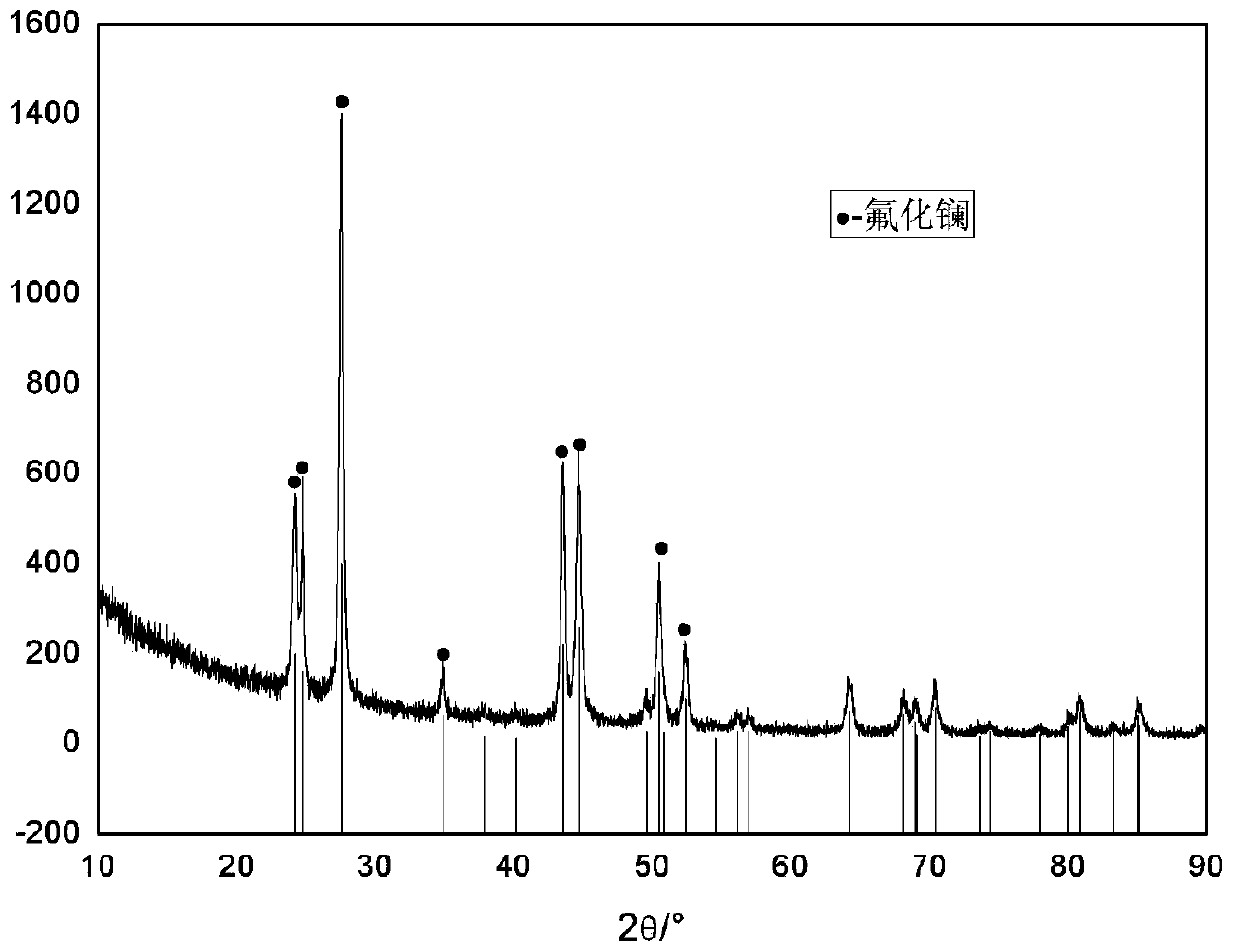

[0032] Mix 100g of lanthanum carbonate and 120g of ammonium fluoride evenly and put them into a corundum crucible, then keep them in a muffle furnace at 150°C for 3h, then raise the temperature to 300°C for 1h to obtain 81g of lanthanum fluoride (the XRD pattern is as follows figure 1 Shown), the product purity is 96.69%.

Embodiment 2

[0034] Mix 200g of lanthanum carbonate and 250g of ammonium fluoride evenly and put them into a corundum crucible, then keep them in a muffle furnace at 120°C for 5h, then raise the temperature to 280°C for 4h to obtain 168.9g of lanthanum fluoride, the product purity is 98.78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com