Solid-solution-doped LLZO inorganic oxide solid electrolyte and preparation method thereof

A technology of inorganic oxides and solid electrolytes, applied in electrolytes, circuits, electrical components, etc., can solve problems such as the need to improve compactness, and achieve the effects of high compactness, high power density, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

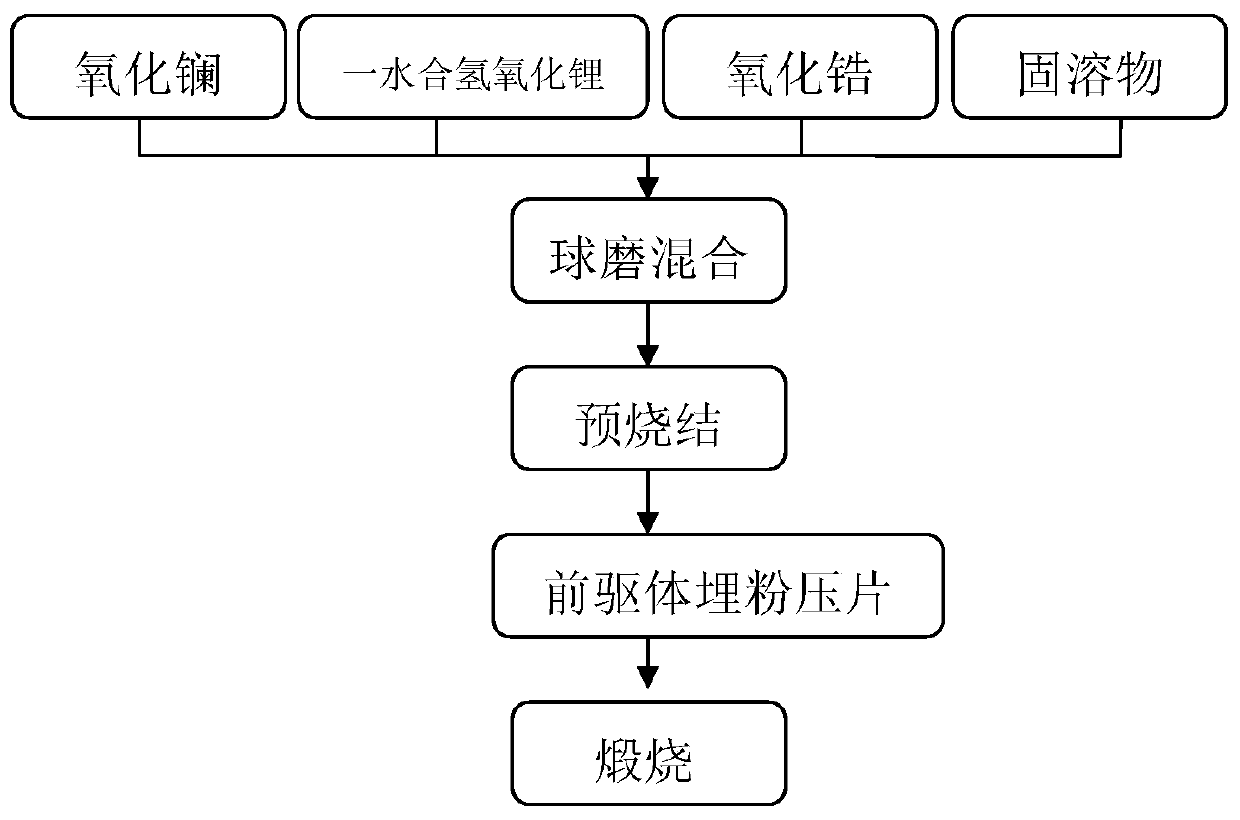

[0053] In a more preferred embodiment, the preparation method includes the following steps:

[0054] (1) the lanthanum trioxide (La 2 o 3 ) was sintered in a muffle furnace at 900°C for 12h, and after sintering, it was mixed with the lithium hydroxide (LiOH) and the zirconium dioxide (ZrO 2 ) mixed, the mixture is also added in proportion to alumina (Al 2 o 3 ), tantalum oxide (Ta 2 o 5 ), niobium oxide (Nb 2 o 5 one or more of );

[0055] (2) the mixture is carried out to wet ball milling;

[0056] (3) drying the raw materials mixed by the ball mill;

[0057] (4) Grinding and refining the dried raw material, and pre-sintering at 950°C for 6 hours to obtain the precursor material;

[0058] (5) adding the tetraethyl orthosilicate to the precursor material, and performing tabletting;

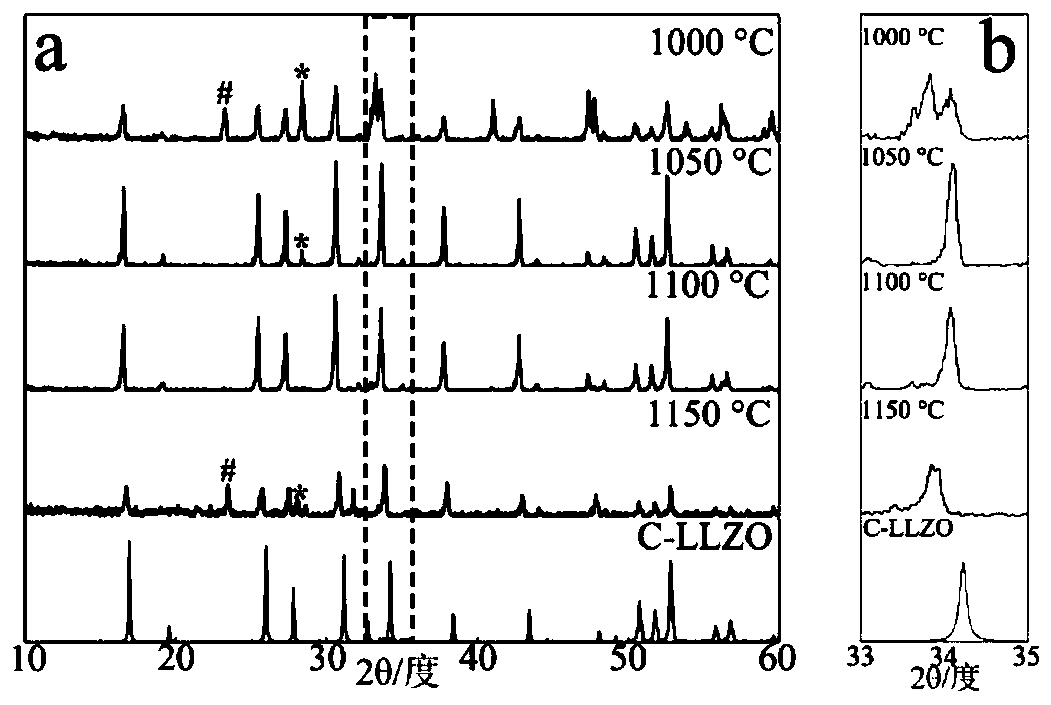

[0059] (6) Calcining the pressed sheet, the calcination temperature is 1000°C, 1050°C, 1100°C or 1150°C, and the calcination time is 12h, to obtain doped Si, and aluminum (Al), tantalum...

Embodiment 1

[0083] Embodiment 1 (doped silicon)

[0084] 5.295gLa 2 o 3 (>99%) was sintered in a muffle furnace at 900°C for 12h, after sintering, with 3.181gLiOH (>99%), 1.324gZrO 2 (>99%) mixing, put into ball mill jar after mixing, take isopropanol as dispersion medium, raw material is carried out wet ball milling 10h (ball mill ball and ball mill jar are all zirconia materials), to ensure that each raw material mixes evenly; Ball-milled and mixed raw materials were dried in a vacuum oven at 80°C for 12 hours; the dried and uniformly mixed raw materials were ground and refined, and pre-sintered at 950°C for 6 hours to obtain precursor materials. The powder tablet press is used for tablet compression (the pressure is 18MPa, and the diameter of the tablet is 13mm); the pressed tablet is subjected to the second step of calcination, and the pressed tablet is covered with precursor material powder during the calcination process to reduce the calcination process. During the sintering proc...

Embodiment 2

[0087] Embodiment 2 (doping Al)

[0088] 4.89gLa 2 o 3 (>99%) was sintered in a muffle furnace at 900°C for 12h, after sintering, with 1.65gLiOH (>99%), 2.46gZrO 2 (>99%), 0.1275g Al 2 o 3 After mixing, put it into a ball mill tank, use isopropanol as the dispersion medium, and wet the raw materials for 10 hours (the balls and the ball mill tank are both made of zirconia) to ensure that the raw materials are mixed evenly; the mixed raw materials are ball milled Dry in a vacuum oven at 80°C for 12 hours; Grind and refine the dried and uniformly mixed raw materials, and pre-sinter at 950°C for 6 hours to obtain the precursor material; weigh a certain mass of the precursor material obtained by pre-sintering, and add positive Ethyl silicate was compressed into tablets by a manual powder tablet press (pressure 18MPa, tablet diameter 13mm); the pressed tablets were calcined in the second step, and different calcination temperatures were set to 1000°C and 1050°C , 1100°C, 1150°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com