Electric-insulation coating and preparation method thereof

A radiation heat dissipation and electrical insulation technology, which is applied in the field of composite coatings, can solve the problems of inability to fully exert the radiation heat dissipation performance of coatings, increase thermal resistance, and potential safety hazards, and achieve the effects of improving processing performance, reducing temperature efficiently, and stabilizing coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

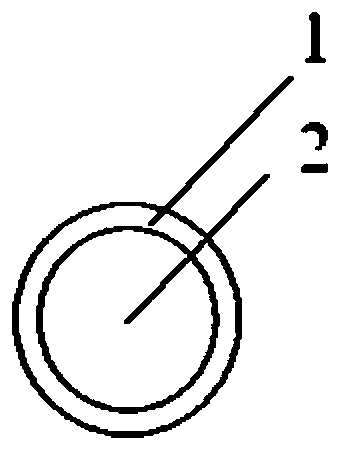

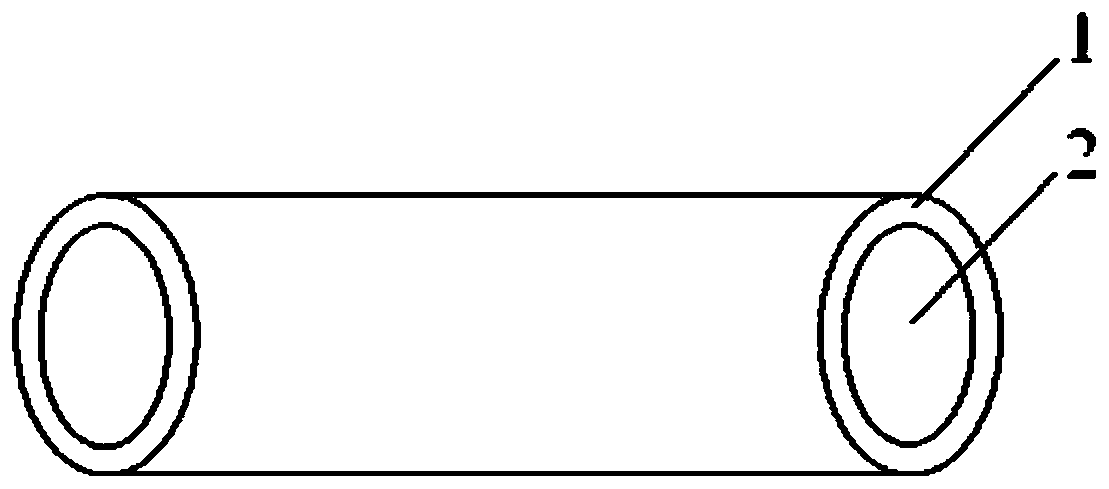

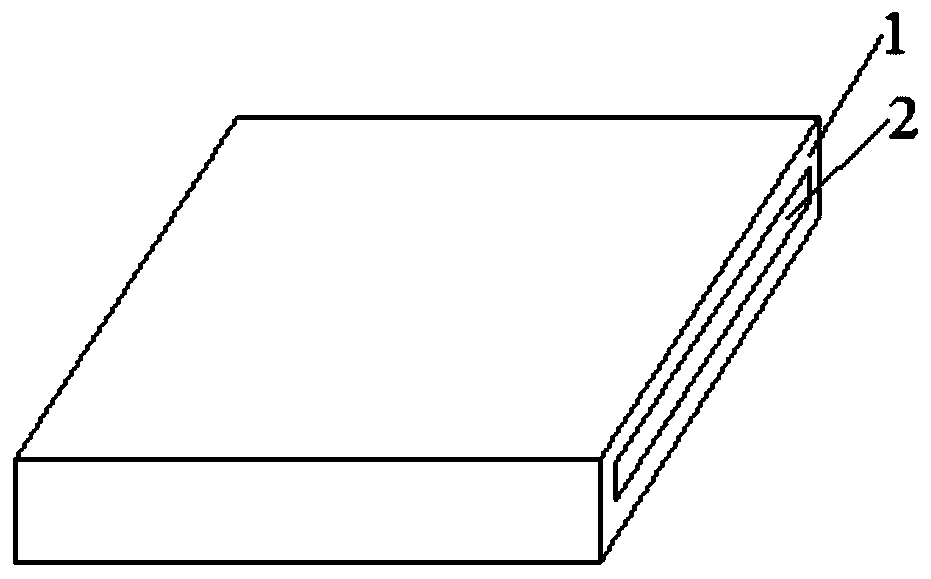

[0040] The electrical insulation radiation heat dissipation coating of this embodiment includes the following raw materials in parts by weight: 100 parts of coating base, 80 parts of composite heat dissipation coating, 5 parts of surfactant, 6 parts of coupling agent, 3 parts of plasticizer, and 16 parts of solvent , 3 parts of dispersant, 2 parts of defoamer. Wherein, the coating matrix is epoxy resin, and the composite heat-dissipating filler is a mixed filler composed of spherical filler and fibrous filler in a weight ratio of 1:1, wherein the core material of the spherical filler is spherical aluminum, and the material of the outer cladding layer is nitrided Silicon, the core material of fibrous filler is carbon nanofiber, the outer cladding layer material is silicon carbide, the surfactant is sodium dodecylbenzenesulfonate, the coupling agent is silane coupling agent, and the plasticizer is o-phthalic acid Diformic acid ester, the solvent is deionized water, the dispers...

Embodiment 2

[0053] The electrical insulating radiation heat dissipation coating of this embodiment includes the following raw materials in parts by weight: 120 parts of coating base, 100 parts of composite heat dissipation coating, 7 parts of surfactant, 9 parts of coupling agent, 2 parts of plasticizer, solvent 20 parts, 2 parts of dispersant, 3 parts of defoamer. Wherein, the coating matrix is silicone rubber, and the composite heat-dissipating filler is a mixed filler composed of spherical filler and flake filler in a weight ratio of 1:1, wherein the core material of the spherical filler is spherical aluminum, and the material of the outer cladding layer is silicon nitride. , the core material of the flaky filler is graphite flakes, the outer cladding material is aluminum nitride, the surfactant is polyvinylpyrrolidone, the coupling agent is silane coupling agent, the plasticizer is alkyl sulfonate, and the solvent is Deionized water, dispersant is fatty acid polyethylene glycol este...

Embodiment 3

[0066] The electrical insulating radiation heat dissipation coating of the present embodiment comprises the following raw materials in parts by weight: 130 parts of coating matrix, 120 parts of composite heat dissipation coating, 9 parts of surfactant, 10 parts of coupling agent, 6 parts of plasticizer, 30 parts of solvent 5 parts, 5 parts of dispersant, 4 parts of defoamer. Wherein, the coating matrix is modified epoxy resin, and the composite heat-dissipating filler is a mixed filler composed of spherical filler, fibrous filler and flake filler in a weight ratio of 1:1:1, wherein the core material of the spherical filler is spherical aluminum, The material of the outer cladding layer is silicon nitride, the core material of the fibrous filler is carbon nanofiber, the material of the outer cladding layer is silicon carbide, the core material of the flake filler is graphite sheet, and the outer cladding material is aluminum nitride. Surfactant is sodium dodecylbenzenesulfona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com