Ceramic membrane, and preparation method and application thereof

A technology of ceramic membrane and loaded membrane, which is applied in the field of separation membrane, can solve the problem that the oil removal efficiency and flux of the ceramic membrane cannot be taken into account, and achieve the effects of simple and fast preparation method, good stability and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

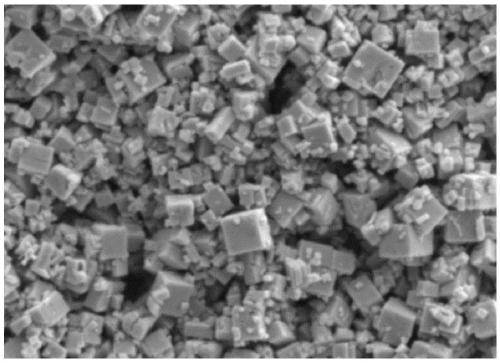

Image

Examples

preparation example Construction

[0046] A second aspect of the present invention provides a method for preparing a ceramic membrane, the method comprising the steps of:

[0047] 1) After uniformly mixing the composition containing alumina and / or zirconia, pore-forming agent and binder, molding and drying;

[0048] 2) coating the mixture containing tungsten-containing compound and organic acid on the product obtained in step 1);

[0049] 3) Sintering the product obtained in step 2) at a high temperature.

[0050]In the present invention, in step 1), molding is used to form the material layer of porous support layer, and in step 2) coating is used to form the material layer of supporting film layer, and in step 3) utilizes above-mentioned material to form mutually stacked porous support layer and the supporting film layer.

[0051] In the above step 1), the alumina and / or zirconia are uniformly mixed with the pore-forming agent and the binder, molded, dried and sintered at high temperature to obtain a porous ...

Embodiment 1

[0079] (1) Weigh 10kg of spherical alumina with a median particle size of 20μm, add pore-forming agent (0.3kg), binder (0.6kg) and tungsten trioxide (1.2kg) with a median particle size of 1.5μm and mix thoroughly Finally, 4.4 kg of water was added and stirred at a low speed for three hours, and then the mud was smelted, and the obtained mixture was placed in a mold and dried at 60° C. for 5 hours to form a porous support layer green body with a thickness of 1.0 cm.

[0080] Wherein, the pore-forming agent is a mixture of starch and charcoal, the starch is amylose, the charcoal is ground through a 500 mesh sieve, and the mass ratio of starch and charcoal is 3:7; the binder is glycerin , a mixture of polylactic acid and polyvinyl alcohol, the average molecular weight of the polylactic acid is 8000, and the molecular weight of the polyvinyl alcohol is 2000; the mass ratio of the glycerin, polylactic acid and polyvinyl alcohol is 5:2: 3.

[0081] (2) Dissolve 100g of sodium tungs...

Embodiment 2

[0087] (1) Weigh 10kg of spherical zirconia with a median particle size of 15μm, add pore-forming agent (0.4kg), binder (0.8kg) and tungsten trioxide (1.2kg) with a median particle size of 1.5μm and mix thoroughly Finally, add 4.3 kg of water and stir at a low speed for three hours to make the mud, place it in a mold and dry it at 60° C. for 5 hours to form a porous support layer green body with a thickness of 0.9 mm. The pore forming agent and the binder composition are the same as in Example 1.

[0088] (2) 100g sodium tungstate is dissolved in 150g of 15% by weight hydrogen peroxide solution, and 50g organic acid solution (the mixed solution of tartaric acid and salicylic acid, the weight ratio of tartaric acid and salicylic acid) is added dropwise by using a syringe pump 1:1 total 20% by weight), stirring while adding dropwise, controlling the dropwise addition time not to exceed 15min, continuing to stir for 2h after the dropwise addition to form a uniform colloidal emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com