Sulfur ion implanted nano diamond-graphene composite film electrode and preparation method thereof

A composite technology of nano-diamond and graphene, which is applied in the direction of ion implantation plating, metal material coating process, gaseous chemical plating, etc. The field of precision electrochemical detection, the influence of electrical and electrochemical performance and other issues, to achieve the effect of excellent electrochemical activity, increased electrochemical active area, and wide potential window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

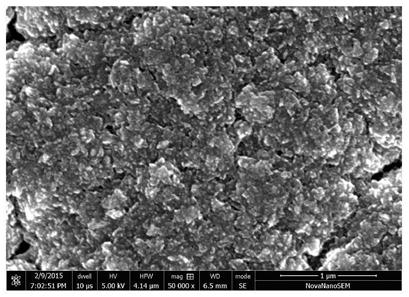

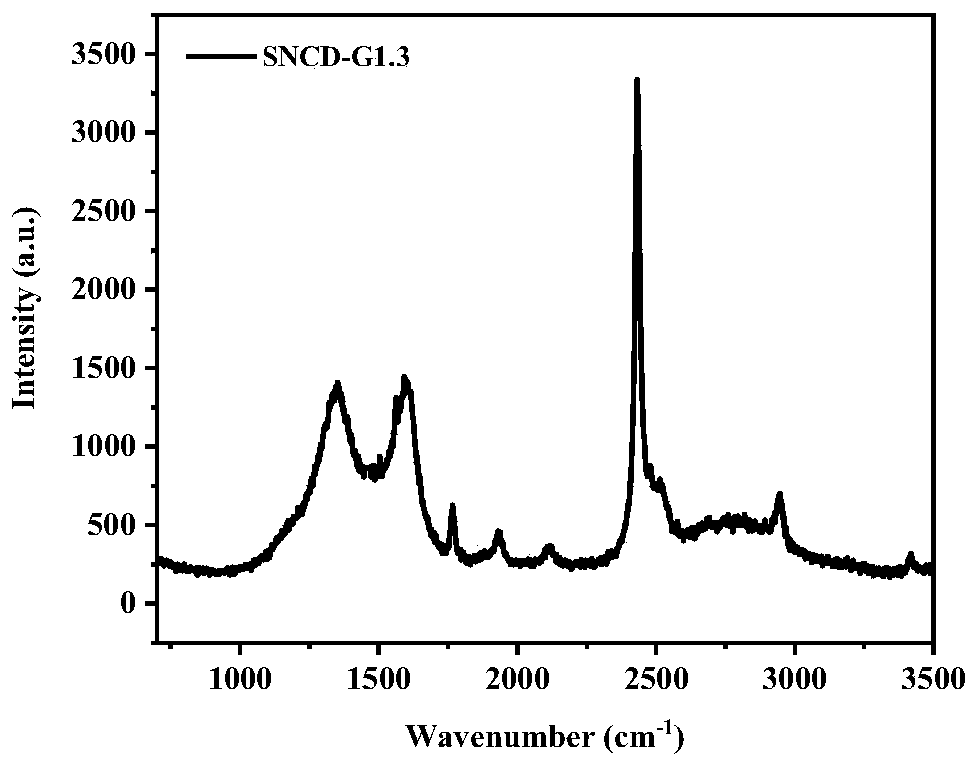

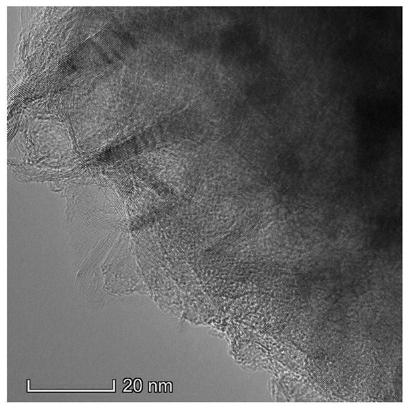

[0042] Diamond powder (purchased from Shanghai Jiye Abrasives Co., Ltd., model w1) and glycerin (glycerin) were mixed in a ratio of 1g:100ml, stirred evenly with a glass rod, placed in an ultrasonic cleaner for ultrasonic dispersion for 5 minutes, and made It is fully and evenly dispersed to form a diamond powder grinding paste, which is reserved for later use; take an appropriate amount of prepared diamond powder grinding paste on the polishing flannelette, and polish the monocrystalline silicon wafer for 30 minutes; Silicon wafers were ultrasonically cleaned in acetone and alcohol solutions for 5 minutes; the cleaned silicon wafers were blown dry with a nitrogen gun, and wrapped with lens cleaning paper for later use.

[0043]Put the seed crystal-finished single crystal silicon substrate into the hot wire chemical vapor deposition equipment, use acetone as the carbon source, and bring the acetone into the reaction chamber by hydrogen bubbling. Among them, the flow ratio of h...

Embodiment 2

[0052] Diamond powder (purchased from Shanghai Jiye Abrasives Co., Ltd., model w1) and glycerin (glycerin) were mixed in a ratio of 1g:100ml, stirred evenly with a glass rod, placed in an ultrasonic cleaner for ultrasonic dispersion for 5 minutes, and made It is fully and evenly dispersed to form a diamond powder grinding paste, which is reserved for later use; take an appropriate amount of prepared diamond powder grinding paste on a polishing flannelette, and polish the monocrystalline silicon wafer for 30 minutes; Silicon wafers were ultrasonically cleaned in acetone and alcohol solutions for 5 minutes; the cleaned silicon wafers were blown dry with a nitrogen gun, and wrapped with lens cleaning paper for later use.

[0053] Put the seed crystal-finished single crystal silicon substrate into the hot wire chemical vapor deposition equipment, use acetone as the carbon source, and bring the acetone into the reaction chamber by hydrogen bubbling. The flow ratio of hydrogen and a...

Embodiment 3

[0062] Diamond powder (purchased from Shanghai Jiye Abrasives Co., Ltd., model w1) and glycerin (glycerin) were mixed in a ratio of 1g:100ml, stirred evenly with a glass rod, placed in an ultrasonic cleaner for ultrasonic dispersion for 5 minutes, and made It is fully and evenly dispersed to form a diamond powder grinding paste, which is reserved for later use; take an appropriate amount of prepared diamond powder grinding paste on a polishing flannelette, and polish the monocrystalline silicon wafer for 30 minutes; Silicon wafers were ultrasonically cleaned in acetone and alcohol solutions for 5 minutes; the cleaned silicon wafers were blown dry with a nitrogen gun, and wrapped with lens cleaning paper for later use.

[0063] Put the seed crystal-finished single crystal silicon substrate into the hot wire chemical vapor deposition equipment, use acetone as the carbon source, and bring the acetone into the reaction chamber by hydrogen bubbling. The flow ratio of hydrogen and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com