BiFeO3/RGO composite wave-absorbing material and preparation method thereof

A technology of composite absorbing materials and composite materials, applied in the field of BFO/RGO composite materials, to achieve the effects of impedance matching and electromagnetic wave attenuation characteristics, strong absorption capacity, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of bismuth ferrite sample

[0027] Preparation of bismuth ferrite powder by hydrothermal method: 1.02 g of ferric nitrate nonahydrate and bismuth nitrate pentahydrate with a corresponding molar ratio of 1:1 were mechanically stirred in 60 mL of deionized water for 30 min, and then transferred to a 100 mL poly The reaction was carried out in a tetrafluoroethylene-lined hydrothermal kettle at 160 °C for 8 h. After the reaction was completed and cooled to room temperature, it was washed three times with deionized water and ethanol respectively, and dried in an oven at 45 °C for 6 h to obtain bismuth ferrite powder.

Embodiment 2

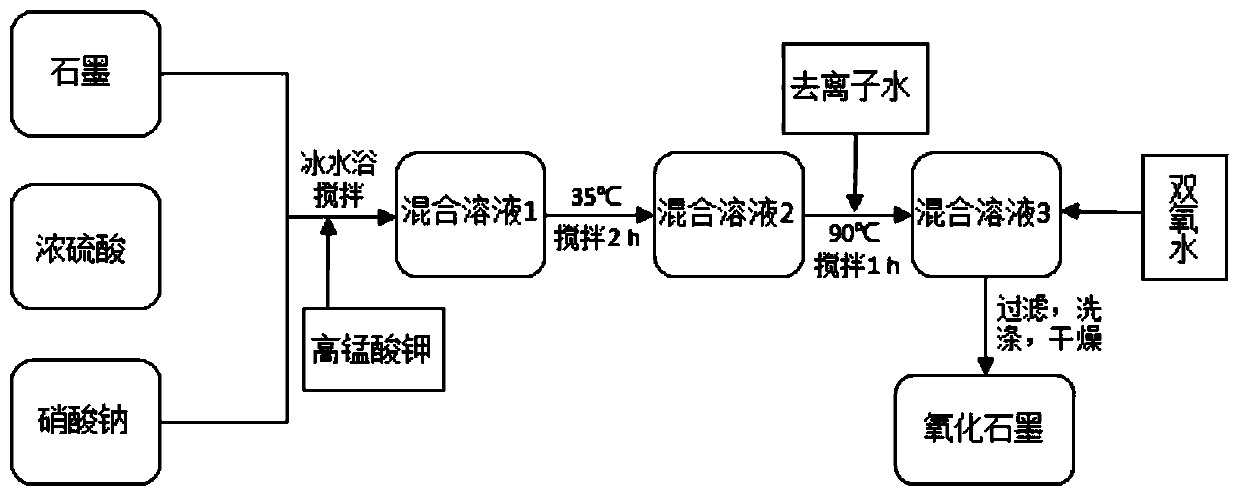

[0028] Example 2 Preparation of graphene oxide samples

[0029] The preparation process is as figure 1 , Weighed 3 g of natural flake graphite and 1.5 g of sodium nitrate in 50 mL of concentrated sulfuric acid solution, and transferred to a three-necked flask, stirred for 0.5 h in an ice bath, and then added 10 g of KMnO 4 Stirring was continued for 2 h, and after the suspension was observed to change from purple to dark green, the temperature was raised to 35°C for 2 h of medium-temperature reaction. Subsequently, the reaction system was fixed in a water bath with a constant temperature of 90 °C. After 2 h of high temperature reaction, 120 mL of deionized water and 10 mL (30%) of hydrogen peroxide solution were added to terminate the reaction and ultrasonic Peel for 1 h. After filtration and washing for 3 times, graphene oxide nanosheets were obtained after drying in an oven at 50 °C for 24 h, and kept for future use.

Embodiment 3

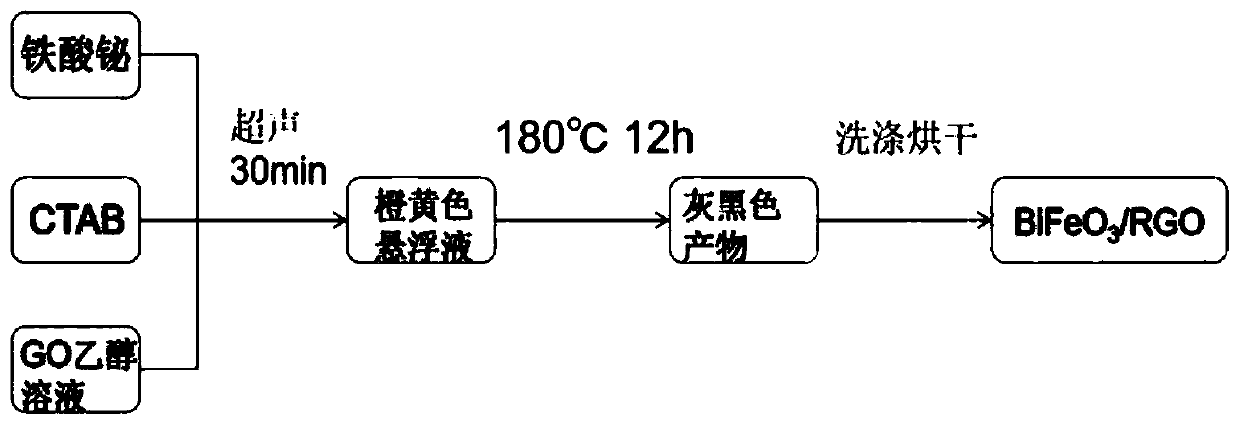

[0030] The preparation of embodiment 3 BFO / RGO composite material

[0031] The preparation process is as figure 2 , add 0.9 g of bismuth ferrite powder and 20 mg of cetyltrimethylammonium bromide into 100 mL of graphene oxide aqueous solution with a concentration of 1 mg / mL, stir and sonicate for 1 h to obtain a yellow-brown stable suspension liquid; then transferred to a 100 mL hydrothermal kettle for reaction at a temperature of 180 °C for 12 h. After cooling to room temperature, the obtained product was washed and filtered three times with deionized water and ethanol, respectively, and dried at 45 °C for 6 h to obtain the BFO / RGO composite material.

[0032] Embodiment 4 and 5 are all prepared by the same preparation method as Embodiment 3. Its composition, dosage and process conditions are shown in Table 1:

[0033] Table 1 Summary of composition, dosage and process conditions of samples 3, 4, and 5 of the example

[0034] raw material Example 3 Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com