Preparation method of modified starch and application

A modification and starch technology, which is applied in the directions of biochemical equipment and methods, applications, and medical preparations containing active ingredients, etc. problems, to achieve the ideal hypoglycemic effect, regulate body weight and blood lipids, and achieve the effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

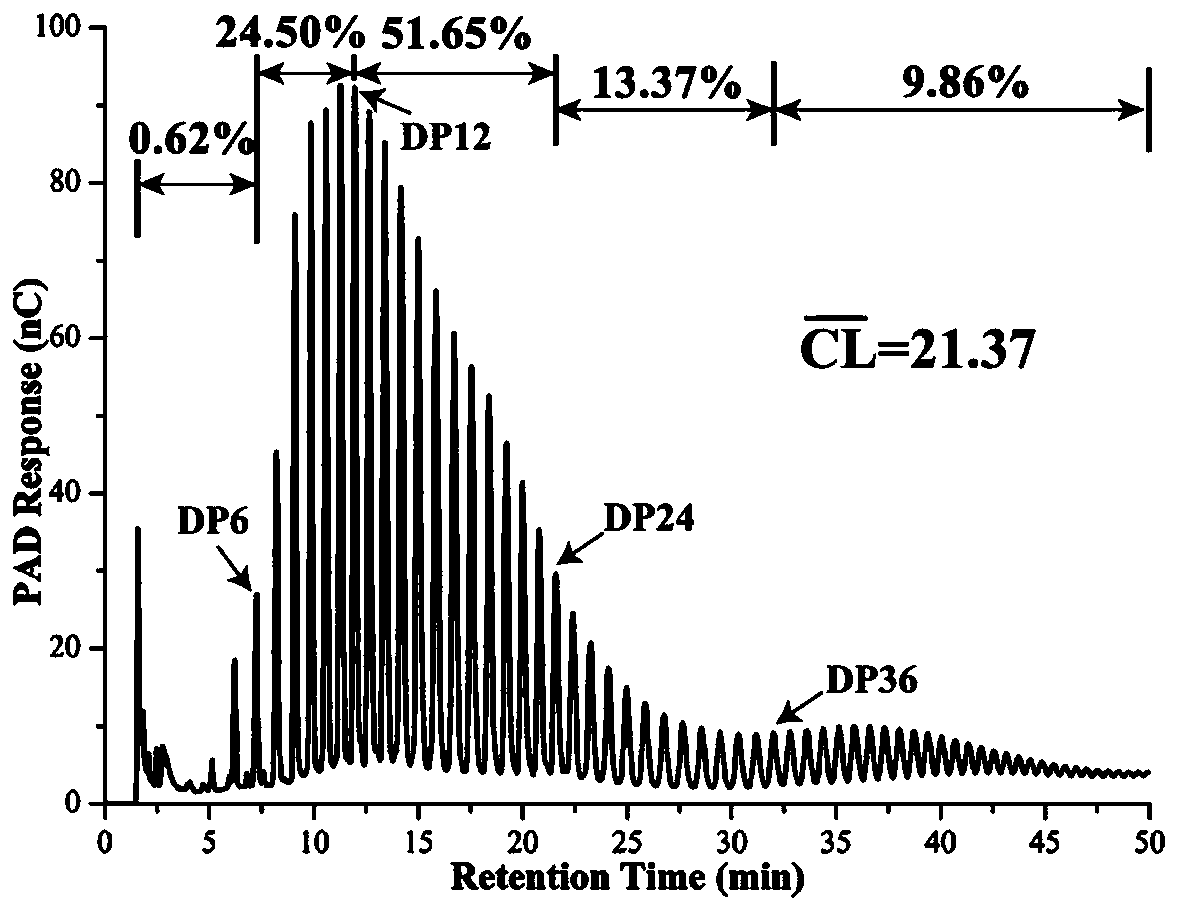

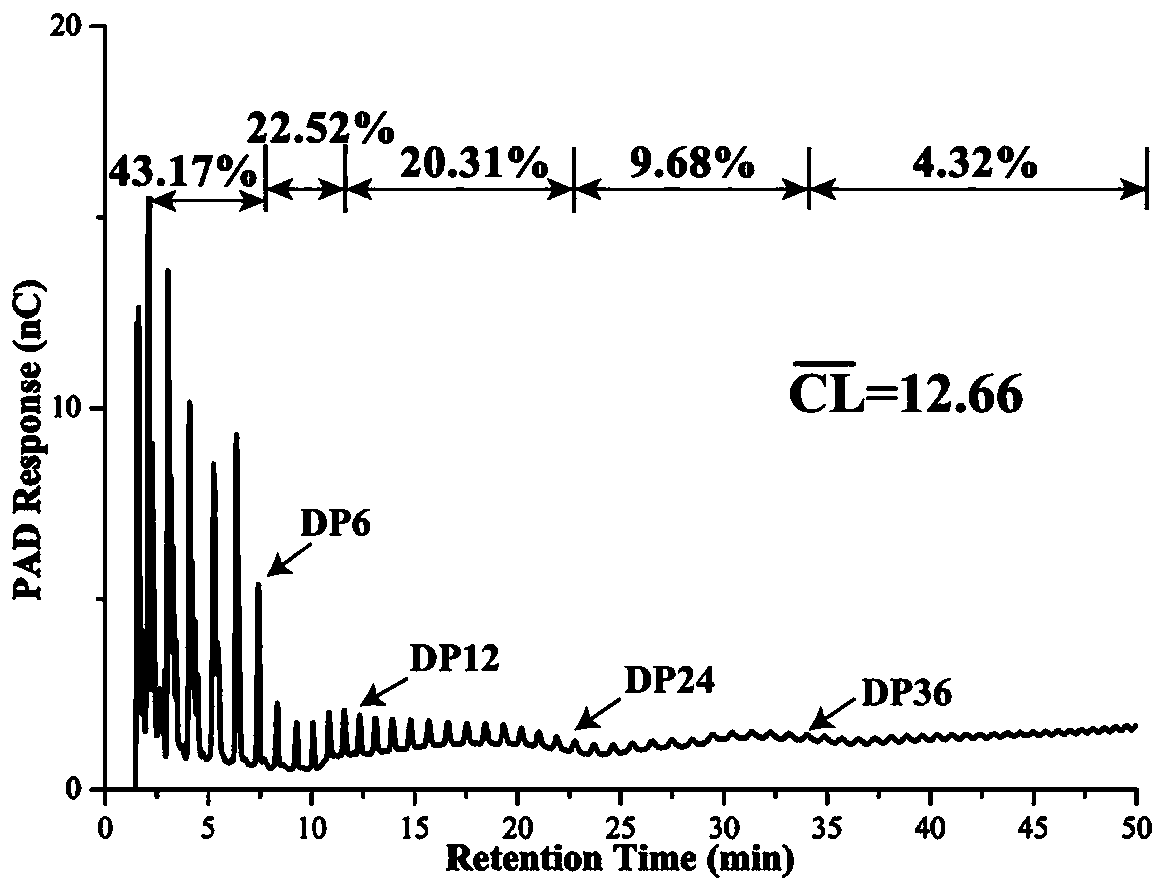

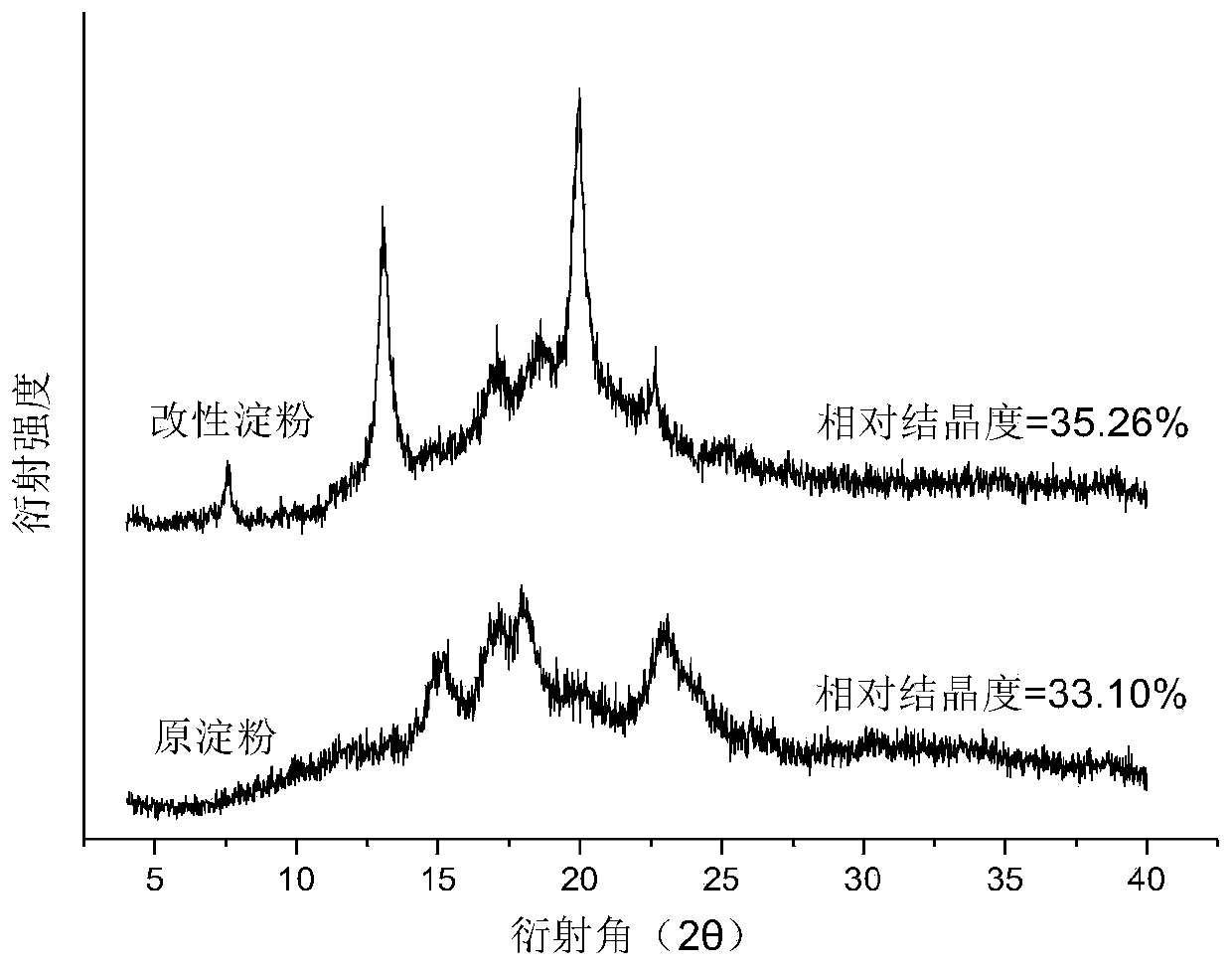

[0034] The invention provides a method for preparing modified starch: adding β-amylase to the starch gelatinization solution for modification, adding branching enzyme to continue the modification after deactivating the enzyme, adding pullulan enzyme to continue the modification after deactivating the enzyme, and deactivating the enzyme Afterwards, the enzymatic hydrolyzate is precipitated with alcohol, and the precipitate is dried to obtain modified starch.

[0035] The source of starch gelatinization liquid can be edible starch such as rice starch, potato starch, yam starch, banana starch. β-amylase from barley (BA, EC 3.2.1.2), branching enzyme from Rhodothermus obamensis (BE, EC 2.4.1.18) and pullulanase from Pullulan solutes nagano (PUL, EC 3.2.1.41 ) to modify the molecular chain structure of starch, and other reagents are commercially available.

[0036] The RS content of natural rice starch is extremely low, but Chinese people eat it more often. Using the rice starch t...

Embodiment 4

[0071] 200mg resistant starch, 36mg GSPA S , 135mg microcrystalline cellulose, 4mg magnesium stearate, and 20mg cross-linked polyvinylpyrrolidone are fully mixed, and the 10% polyvinylpyrrolidone solution prepared in 50% ethanol solution is used as a binder to make a soft material. Experience "Hold it into a ball, pinch it and break it";

[0072] Granulation: sieve the soft materials to make wet granules;

[0073] Dry the wet granules, set the drying temperature to 45°C, gradually raise the temperature to 60°C, and dry until the moisture content of the granules is 2%;

[0074] Grain sizing: the dried granules are sieved to obtain granules with suitable particle size;

[0075] Tablet compression: After granulation, add 2-4% magnesium stearate to the granules by external addition method, mix evenly, adjust the pressure of the tablet machine, fill the granules into the tablet mold for tablet compression;

[0076] Inspection: Check the tablet appearance, tablet weight differenc...

Embodiment 5

[0079] 150mg resistant starch, 30mg GSPA S , 150mg microcrystalline cellulose, 8mg magnesium stearate, and 25mg cross-linked polyvinylpyrrolidone are fully mixed, and 15% polyvinylpyrrolidone solution prepared in 50% ethanol solution is used as a binder to make a soft material. Experience "Hold it into a ball, pinch it and break it";

[0080] Granulation: sieve the soft materials to make wet granules;

[0081] Dry the wet granules, set the drying temperature to 45°C, gradually raise the temperature to 60°C, and dry until the moisture content of the granules is 3%;

[0082] Grain sizing: the dried granules are sieved to obtain granules with suitable particle size;

[0083] Tablet compression: After granulation, add 2-4% magnesium stearate to the granules by external addition method, mix evenly, adjust the pressure of the tablet machine, fill the granules into the tablet mold for tablet compression;

[0084] Inspection: Check the tablet appearance, tablet weight difference, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com